A corrosion test device and method for liquid lead or liquid lead-bismuth alloy

A liquid lead-bismuth alloy, corrosion test technology, applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., to achieve the effect of ensuring accuracy and reliability, simple structure, and meeting the needs of high temperature operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

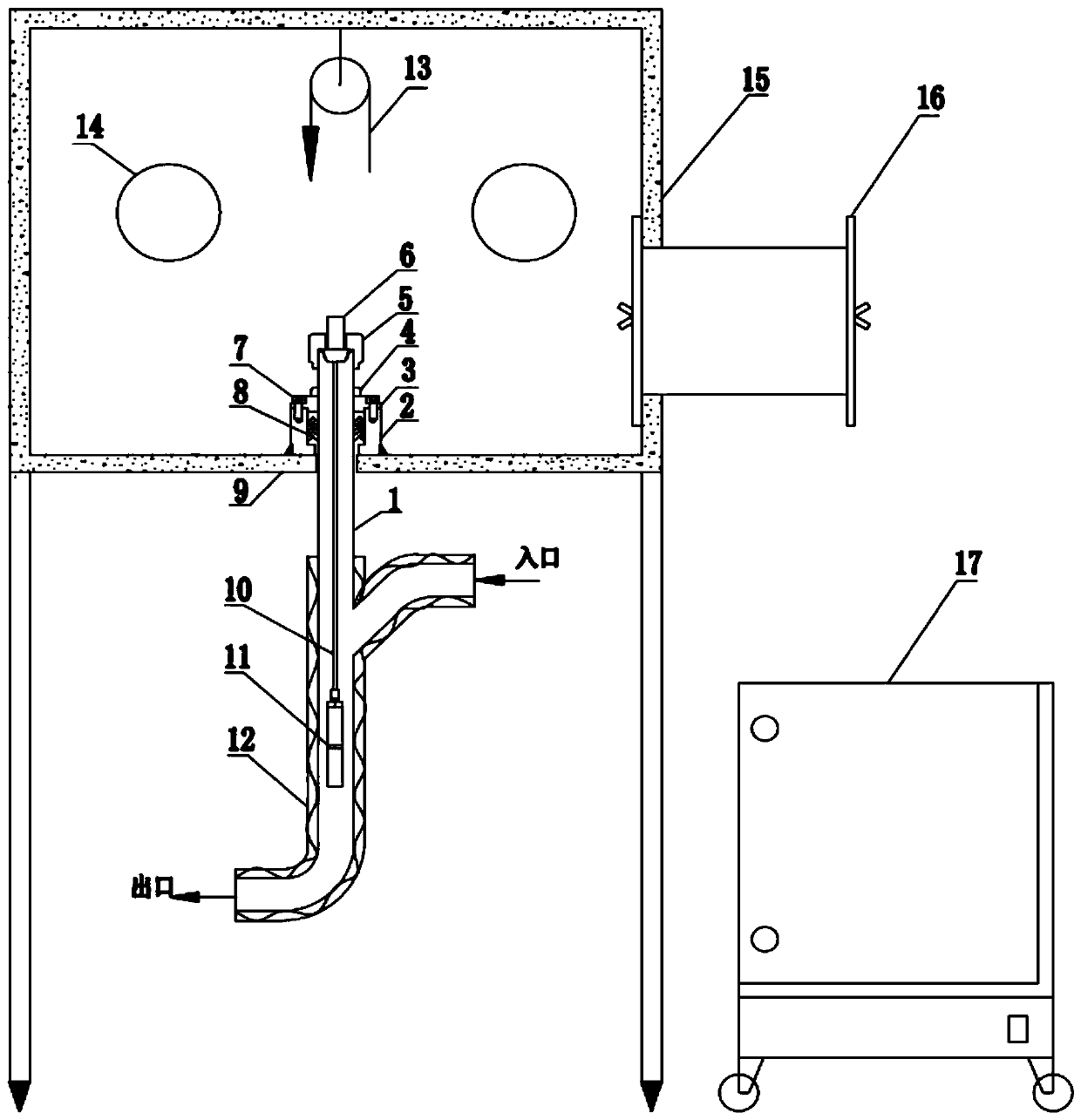

[0057] Such as figure 1 with figure 2 As shown, the present embodiment provides a specific implementation of a corrosion test device for liquid lead or liquid lead-bismuth alloy. The device includes a box, and the box is provided with a box-shaped glove box 15 , also includes a flange 2 fixed on the bottom plate 9 of the glove box 15, the bottom plate 9 is provided with a communication hole, and the communication hole communicates with the central hole of the flange 2;

[0058] Also includes the test section body 1, the upper end of the test section body 1 has a straight pipe section in the shape of a straight pipe, the upper end of the straight pipe section is inserted into the glove box 15 through the communicating hole, and the side of the straight pipe section is also provided with a Introduce the inlet branch pipe of liquid lead or liquid lead-bismuth alloy in the straight pipe section, and the inlet branch pipe is positioned at the bottom of the bottom plate 9;

[005...

Embodiment 2

[0082] The present embodiment is further limited on the basis of embodiment 1, as figure 1 with 2 As shown, for the convenience of lifting and releasing the connecting body of the sealing head 6 and the support bar 10, a lifting device 13 arranged in the glove box 15 is also included, and the lifting device 13 is positioned directly above the sealing head 6, and the lifting device 13 For lifting and releasing the head 6. There are many types of lifting devices 13 in the prior art, and it is preferable to set the lifting device 13 as a ratchet lifting device 13 with a simple structure, light weight, and a purely mechanical structure to facilitate reliable performance in a certain high temperature environment.

[0083] In order to facilitate the transfer operation of the corrosion sample 11, the sampling operation window 14 is arranged on the side of the glove box 15, the transition cabin 16 is arranged on the side of the glove box 15, and the side where the sampling operation ...

Embodiment 3

[0092] The present embodiment provides a kind of concrete test method on the basis of embodiment 1 or 2, comprises the following steps of carrying out in sequence:

[0093] S1. Complete the connection between the test section body 1 and the flange 2, complete the connection between the corrosion sample and the support rod 10, and complete the connection between the support rod 10 and the test section body 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com