Production process of automobile air conditioner condenser coreless flow collecting pipe

A technology of automobile air conditioner and production process, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc. It can solve the problems of unsightly external solder joints of the finished product of the condenser, easy to pollute the environment, crystallization residue, etc., and achieve labor cost saving , Save the spraying step, save the effect of flux consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

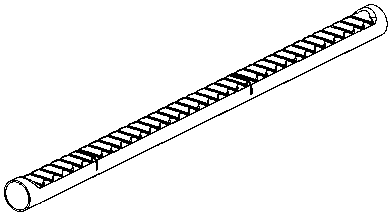

[0022] Embodiment: a kind of such as figure 1 The production process of the coreless header of the automobile air-conditioning condenser shown includes the following steps:

[0023] Step 1: Clean the pure aluminum plate as the substrate with pure water at a temperature of 75-85°C, then blow dry at a drying temperature of 95-100°C, and then cool it to room temperature naturally, and use an aliphatic hydrocarbon solvent on the surface of the dried substrate Wash 2-3 times, rinse again with pure water at a temperature of 50°C, and finally blow dry with a fan for use;

[0024] Step 2: Take two substrates after step 1, sandwich a composite plate between the two substrates to form a three-layer composite structure, wherein the composite plate is made of aluminum powder and flux, and the aluminum powder and flux The component ratio is 7:3;

[0025] Step 3: Pass the three-layer composite structure obtained in Step 2 through a plate rolling machine to obtain an oblate condenser corel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com