Preparing method for tin-based bearing alloy

A tin-based bearing alloy and silicon alloy technology, applied in the field of bearing alloys, can solve the problems of poor adhesion between alloys and steel shells, alloy composition segregation, casting defects, etc., so as to reduce porosity defects, reduce gas content, and improve wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

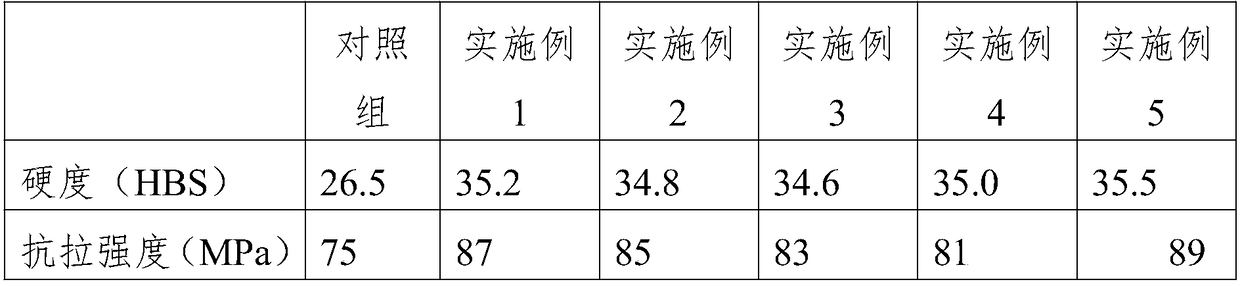

Examples

Embodiment 1

[0021] a. Mix pure tin ingots, pure copper ingots, pure antimony ingots, pure aluminum ingots, pure boron powder, 50% tin-silicon alloy, and 10% tin-titanium alloy according to the mass percentage content of each component in the tin-based bearing alloy : Copper: 4.5%, Antimony: 8%, Titanium: 0.45%, Aluminum: 1.4%, Silicon: 0.7%, Boron: 0.3%, and the rest is tin;

[0022] b. First put 1 / 2 of the pure tin ingot in the above ingredients into the bottom of the crucible, then add 50% tin-silicon alloy, 10% tin-titanium alloy and pure boron powder in turn, heat and melt and then add the remaining pure tin ingot To adjust the temperature, finally add pure copper ingots, pure antimony ingots and pure aluminum ingots;

[0023] c. When the heating temperature rises steadily to 500-550°C, the comprehensive treatment agent can be added immediately for refining and deterioration treatment, and the slag is removed and left to stand for a period of time;

[0024] d. Preheat the steel ingot...

Embodiment 2

[0026] a. Mix pure tin ingots, pure copper ingots, pure antimony ingots, pure aluminum ingots, pure boron powder, 50% tin-silicon alloy, and 10% tin-titanium alloy according to the mass percentage content of each component in the tin-based bearing alloy : Copper: 4.7%, Antimony: 8.5%, Titanium: 0.48%, Aluminum: 1.3%, Silicon: 0.9%, Boron: 0.2%, and the rest is tin;

[0027] b. First put 1 / 2 of the pure tin ingot in the above ingredients into the bottom of the crucible, then add 50% tin-silicon alloy, 10% tin-titanium alloy and pure boron powder in turn, heat and melt and then add the remaining pure tin ingot To adjust the temperature, finally add pure copper ingots, pure antimony ingots and pure aluminum ingots;

[0028] c. When the heating temperature rises steadily to 500-550°C, the comprehensive treatment agent can be added immediately for refining and deterioration treatment, and the slag is removed and left to stand for a period of time;

[0029] d. Preheat the steel ing...

Embodiment 3

[0031] a. Mix pure tin ingots, pure copper ingots, pure antimony ingots, pure aluminum ingots, pure boron powder, 50% tin-silicon alloy, and 10% tin-titanium alloy according to the mass percentage content of each component in the tin-based bearing alloy : Copper: 5.1%, Antimony: 9.5%, Titanium: 0.61%, Aluminum: 1.9%, Silicon: 1.1%, Boron: 0.4%, and the rest is tin;

[0032] b. First put 1 / 2 of the pure tin ingot in the above ingredients into the bottom of the crucible, then add 50% tin-silicon alloy, 10% tin-titanium alloy and pure boron powder in turn, heat and melt and then add the remaining pure tin ingot To adjust the temperature, finally add pure copper ingots, pure antimony ingots and pure aluminum ingots;

[0033] c. When the heating temperature rises steadily to 500-550°C, the comprehensive treatment agent can be added immediately for refining and deterioration treatment, and the slag is removed and left to stand for a period of time;

[0034] d. Preheat the steel ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com