A kind of thermal insulation coating and preparation method thereof

A thermal insulation and coating technology, which is applied in the direction of fireproof coatings, antifouling/underwater coatings, reflection/signal coatings, etc., can solve the problems of weather resistance, insufficient chemical resistance, low requirements for equipment and reaction conditions, and thermal insulation performance. and poor storage stability, to achieve remarkable thermal insulation effects, low requirements for equipment and reaction conditions, and good thermal insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

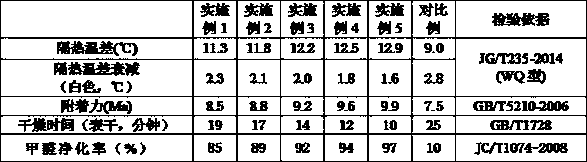

Examples

Embodiment 1

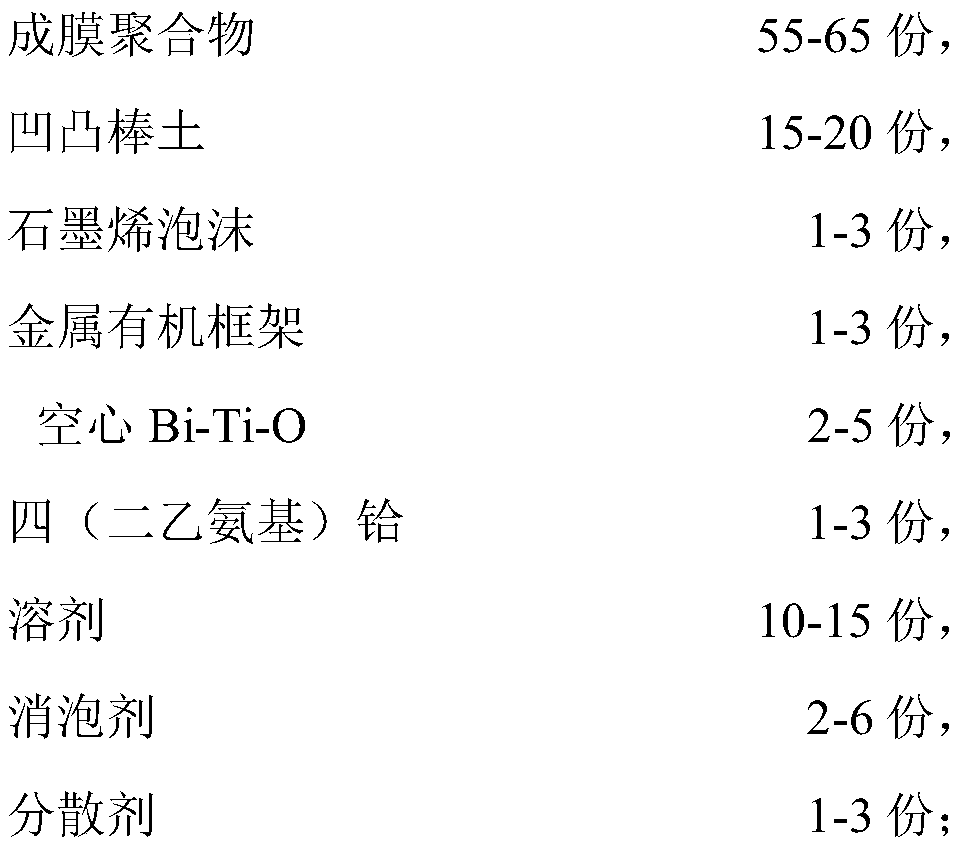

[0035] A thermal insulation coating, made of the following components by weight:

[0036] 55 parts of film-forming polymer,

[0037] Attapulgite 15 parts,

[0038] 1 part graphene foam,

[0039] Metal organic framework MOF-5 1 part,

[0040] Hollow Bi-Ti-O 2 parts,

[0041] Tetrakis(diethylamino) hafnium 1 part,

[0042] 10 parts of water,

[0043] 2 parts of tributyl phosphate,

[0044] Sodium hexametaphosphate 1 part.

[0045] The preparation method of the film-forming polymer comprises the following steps: 10 g of ethyl 2-chloroacrylate, 10 g of tris(2-methoxyethoxy) vinyl silane, 10 g of 2-ethyl cyanoacrylate, Add 0.3 g of azodiisobutyronitrile into 80 g of dimethyl sulfoxide, stir and react at 55°C for 2 hours under a nitrogen atmosphere, then precipitate in acetone, and place it in a vacuum drying oven at 70°C for 10 hours to obtain the compound film polymer.

[0046] The preparation method of the hollow Bi-Ti-O comprises the following steps: adding 0.5 g of bis...

Embodiment 2

[0049] A thermal insulation coating, made of the following components by weight:

[0050] 58 parts of film-forming polymer,

[0051] Attapulgite 16 parts,

[0052] Graphene foam 2 parts,

[0053] Metal organic framework ZIF-8 2 parts,

[0054] Hollow Bi-Ti-O 3 parts,

[0055] Tetrakis(diethylamino)hafnium 2 parts,

[0056] 12 parts of propylene glycol methyl ether,

[0057] Antifoaming agent Deqian 3100 3 parts,

[0058] Polycarboxylate sodium salt 2 parts.

[0059] The preparation method of the film-forming polymer comprises the following steps: 10 g of ethyl 2-chloroacrylate, 10 g of tris(2-methoxyethoxy) vinyl silane, 10 g of 2-ethyl cyanoacrylate, Add 0.35 g of nitrogen diisoheptanonitrile into 85 g of N,N-dimethylformamide, stir and react at 58°C for 2.3 hours under a nitrogen atmosphere, then precipitate in acetone, and dry in a vacuum oven at 72°C After 12 hours, a film-forming polymer was obtained.

[0060] The preparation method of the hollow Bi-Ti-O comprise...

Embodiment 3

[0063] A thermal insulation coating, made of the following components by weight:

[0064] 60 parts of film-forming polymer,

[0065] Attapulgite 18 parts,

[0066] Graphene foam 2 parts,

[0067] Metal organic framework HKUST-1 2 parts,

[0068] Hollow Bi-Ti-O 3 parts,

[0069] Tetrakis(diethylamino)hafnium 2 parts,

[0070] 13 parts of ethanol,

[0071] Defoamer BYK088 5 parts,

[0072] Sodium hexametaphosphate 2 parts.

[0073] The preparation method of the film-forming polymer comprises the following steps: 10 g of ethyl 2-chloroacrylate, 10 g of tris(2-methoxyethoxy) vinyl silane, 10 g of 2-ethyl cyanoacrylate, Add 0.4 g of N-diisoheptanonitrile to 95 g of N-methylpyrrolidone, stir and react at 60°C for 2.6 hours under a nitrogen atmosphere, then precipitate in acetone, and place it in a vacuum drying oven at 76°C for 13 hours to obtain Film-forming polymers.

[0074] The preparation method of the hollow Bi-Ti-O comprises the following steps: adding 0.5 g of bismu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com