Halogen-free resin composition and flexible copper clad laminate prepared thereby

A technology of resin composition and mixture, which is applied in the direction of epoxy resin glue, synthetic resin layered products, adhesive types, etc., can solve the problems that flexible copper clad laminates cannot meet the technical requirements, and achieve excellent toughening effect and reaction Excellent activity and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

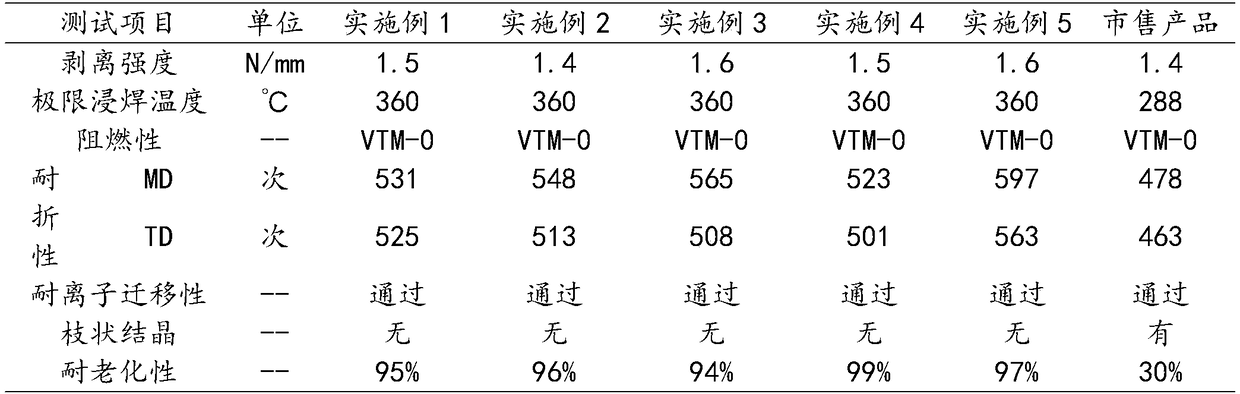

Examples

Embodiment 1

[0035] 1. Halogen-free resin composition

[0036] 1. The halogen-free resin composition includes 5 parts of polyurethane modified epoxy resin (HyPox UA10), 20 parts of phenolic novolak epoxy resin, 40 parts of polyurethane and polyamide block copolymer, 10 parts of MQ resin, dicyandiamide 5 parts of amine, 0.2 part of 2-methylimidazole, 15 parts of phosphorus-containing flame retardant SPB-1001.

[0037] 2. The amine value of the polyurethane and polyamide block copolymer is 12mgKOH / g, wherein the number average molecular weight of the polyurethane segment is 1500, and the glass transition temperature Tg is -40°C; the number average molecular weight of the polyamide segment is 3000, the glass transition temperature Tg is 10°C; polyamide segments account for 60% of the total moles of polyurethane and polyamide segments in the copolymer, and polyurethane segments account for 40% of the total moles of polyurethane and polyamide segments in the copolymer %.

[0038] 3. Dissolvin...

Embodiment 2

[0042] 1. Halogen-free resin composition

[0043] 1. The halogen-free resin composition includes 7 parts of polyurethane modified epoxy resin (HyPox UA11), 25 parts of bisphenol A novolac epoxy resin, 45 parts of polyurethane and polyamide block copolymer, 12 parts of MQ resin, 5 parts of m-phenylenediamine, 0.3 parts of 2-undecylimidazole, and 18 parts of phosphorus-containing flame retardant (OP-935).

[0044] 2. The amine value of the polyurethane and polyamide block copolymer is 15mgKOH / g, wherein the number average molecular weight of the polyurethane segment is 1800, and the glass transition temperature Tg is -35°C; the number average molecular weight of the polyamide segment is 3500, the glass transition temperature Tg is 15°C; polyamide segments account for 70% of the total moles of polyurethane and polyamide segments in the copolymer, and polyurethane segments account for 30% of the total moles of polyurethane and polyamide segments in the copolymer %.

[0045] 3. D...

Embodiment 3

[0049] 1. Halogen-free resin composition

[0050] 1. The halogen-free resin composition includes 9 parts of polyurethane modified epoxy resin (NPER-133L), 28 parts of o-cresol novolac epoxy resin, 55 parts of polyurethane and polyamide block copolymer, 17 parts of MQ resin, 8 parts of 4,4'-diaminodiphenylsulfone, 0.5 parts of 2-phenylimidazole, and 20 parts of phosphorus-containing flame retardant (OP-930).

[0051] 2. The amine value of the polyurethane and polyamide block copolymer is 18mgKOH / g, wherein the number average molecular weight of the polyurethane segment is 2200, and the glass transition temperature Tg is -20°C; the number average molecular weight of the polyamide segment is 4500, the glass transition temperature Tg is 20°C; polyamide segments account for 80% of the total moles of polyurethane and polyamide segments in the copolymer, and polyurethane segments account for 20% of the total moles of polyurethane and polyamide segments in the copolymer %.

[0052] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com