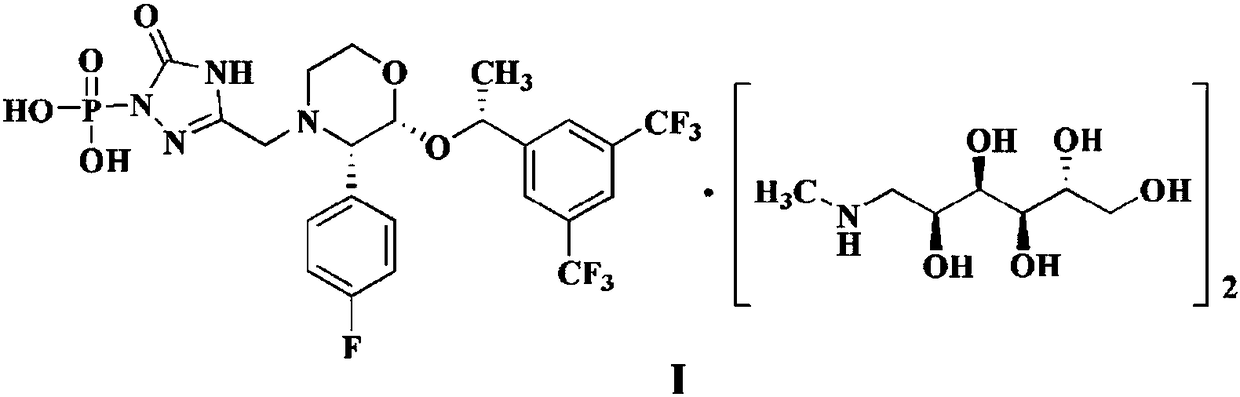

Preparation method of fosaprepitant dimeglumine pharmaceutical salt

A fosaprepitant and intermediate technology, applied in a new field of preparation of fosaprepitant dimeglumine, to achieve the effects of enlarged production scale, good appearance and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

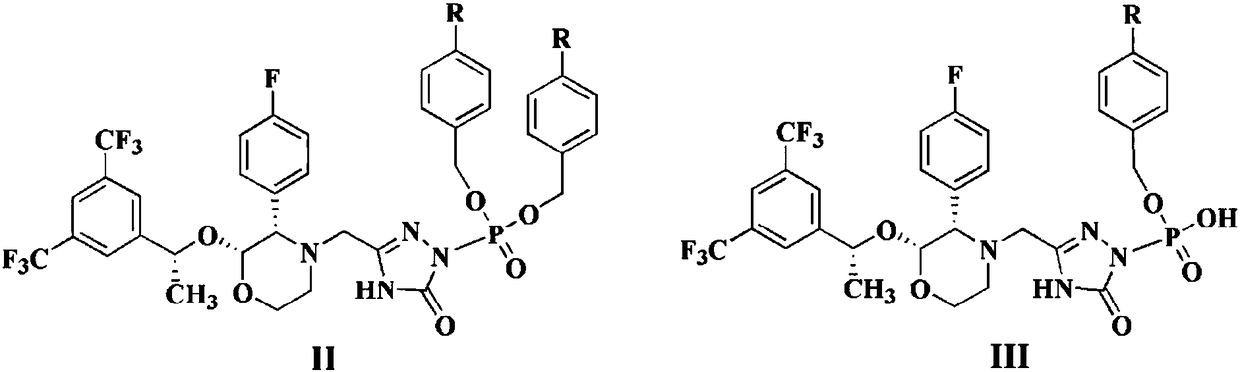

[0025] Example 1: [3-[2(R)-[(1R)-1-[3,5-bis(trifluoromethyl)phenyl]ethoxy]-3(S)-(4-fluorobenzene Base)-4-morpholin-4-yl]methyl]-5-oxo-4,5-dihydro-[1,2,4]-triazol-1-yl]dibenzyl phosphate (IIa) preparation of

[0026] 300ml of tetrahydrofuran, 14.0g of aprepitant, and 22.3g of tetrabenzyl pyrophosphate were sequentially added into the reaction flask, protected by nitrogen, and cooled to 0-10°C. Add 33.6 kg of sodium hexamethyldisilazane solution while controlling the temperature at 0-10°C. After the addition was completed, the reaction was incubated for 1 hour. The reaction was quenched with saturated sodium bicarbonate solution and extracted with methyl tert-butyl ether. The organic layer was washed with 0.5M potassium bisulfate solution, saturated sodium bicarbonate solution and saturated sodium chloride solution, and dried over anhydrous sodium sulfate. Filter and concentrate to obtain a yellow oil. Add 300ml of cyclohexane and stir at 5-15°C for 2-3 hours. After filtra...

Embodiment 2

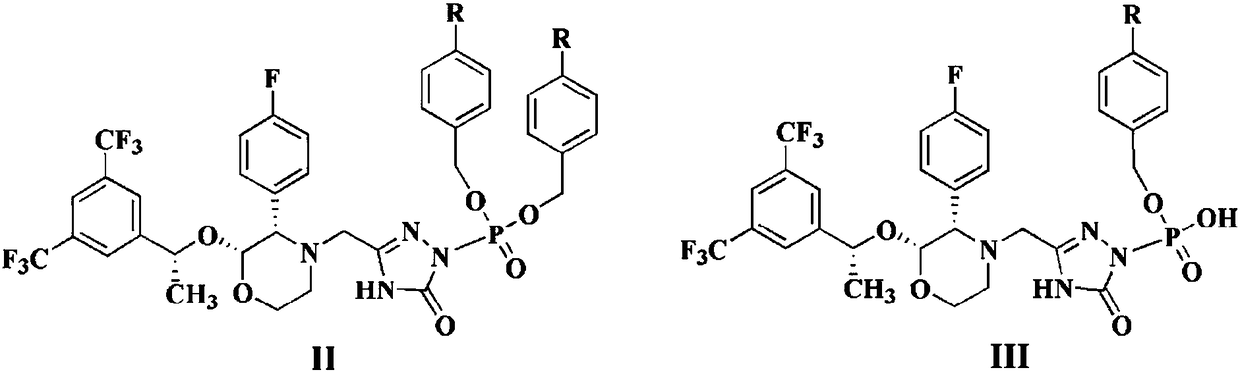

[0027] Example 2 [3-[2(R)-[(1R)-1-[3,5-bis(trifluoromethyl)phenyl]ethoxy]-3(S)-(4-fluorophenyl )-4-morpholin-4-yl]methyl]-5-oxo-4,5-dihydro-[1,2,4]-triazol-1-yl]monobenzyl phosphate (IIIa) preparation

[0028] Add 50ml of methanol and 10.0g of intermediate IIa to the reaction flask, stir at 40-50°C for 8 hours, cool to 0-5°C, keep stirring for 2-3 hours, filter, and vacuum-dry the filter cake for 2-3 hours to obtain White solid 8.0g, yield 89.8%.

Embodiment 3

[0029] The preparation of embodiment 3 fosaprepitant dimeglumine crude product

[0030] Add 5.0g of intermediate IIa, 2.8g of N-methyl-D glucamine, 0.5g of 10% palladium carbon, 1.9g of triethylsilane and 50ml of methanol into the reaction flask, and stir at room temperature for 2 hours. After the reaction, remove the palladium carbon by filtration, add 150ml of isopropanol to the filtrate, stir and crystallize, filter, and vacuum-dry the filter cake for 5-6 hours to obtain 5.1 g of white solid, with a yield of 80.7%. HPLC purity 99.5%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com