Triphenylamino dendrimer ligand substituted silicon phthalocyanine and its preparation method and application

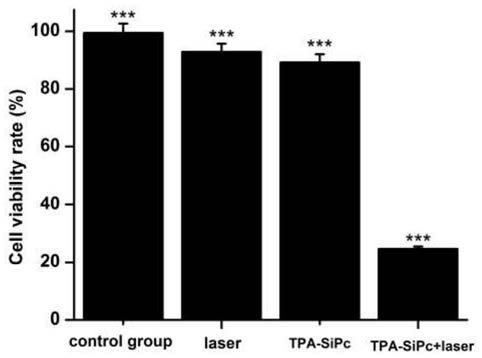

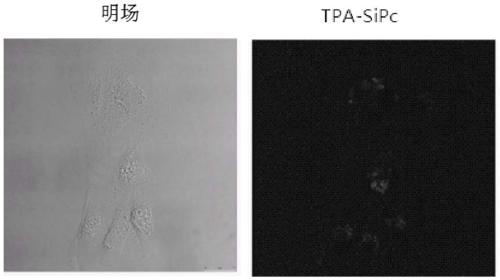

A technology of triphenylamine-based and silicon phthalocyanine, which is applied in the field of triphenylamine-based dendritic ligands substituted for silicon phthalocyanine and its preparation, to achieve the effects of inhibiting aggregation behavior and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

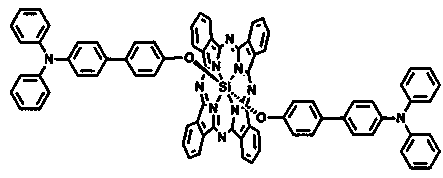

[0022] 1) Dichlorosilicon phthalocyanine (SiPcCl 2 )Synthesis

[0023] Add 1,3-diiminoisoindoline (7.28 g, 50.15 mmol), silicon tetrachloride (8.3 mL) and quinoline (83 mL) respectively into a three-necked flask, stir and reflux for 30 min at 220 °C , cooled to room temperature, poured into 500mL methanol solution, stirred and stood for about 1h, filtered, and the filter residue was washed with 35 mL each of acetone, methanol, dichloromethane, methanol and other solvents, and after drying, 3.6759 g of purple solid was obtained. The yield was 48.62%.

[0024] ) Synthesis of 4'-(diphenylamino)-[1,1'-biphenyl]-4-ol (abbreviated as TPA-OH in the present invention)

[0025] 4-Bromotriphenylamine (1.260 g, 3.89 mmol), 4-hydroxyphenylboronic acid (0.532 g, 3.86 mmol), tetrakis(triphenylphosphine) palladium Pd(PPh 3 ) 4 (0.140 g, 0.120 mmol), after anhydrous and anaerobic operation, inject THF (50 mL) and 2M K 2 CO 3 (25 mL) and the reaction mixture was stirred and refluxed at ...

Embodiment 2

[0031] The specific steps are the same as in Example 1: in process 2), 4-bromotriphenylamine was changed to (2.52 g, 7.98 mmol), 4-hydroxyphenylboronic acid was changed to (1.06 g, 7.72 mmol), and the reaction temperature was changed to 90°C; The time was changed to 36 h. Other reaction conditions were the same, and 0.62 g of tan powder was obtained with a yield of 23.8%.

[0032] The specific steps are the same as in Example 1: in process 3), dichlorosilicon (IV) phthalocyanine is changed to (0.40 g, 0.654 mmol), TPA-OH is changed to (0.66 g, 1.96 mmol)), and the reaction temperature is changed to 150 o C, the reaction time was changed to 96 h. 8 mg of blue powder was obtained with a yield of 1%.

Embodiment 3

[0034] Concrete steps are the same as embodiment one: K in process 3) 2 CO 3 (0.09 g, 0.654 mmol) was changed to NaH (0.01 g, 0.654 mmol), and other reaction conditions were the same. 5.6 mg of blue powder was obtained with a yield of 1.4%.

[0035] Process 3) K 2 CO 3 (0.09 g, 0.654 mmol) was changed to pyridine (0.05 g, 0.654 mmol), and other reaction conditions were the same. 5.8 mg of blue powder was obtained with a yield of 1.46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com