Method for inhibiting aggregation of proteins in aqueous solution and modifying physical property of proteins, product obtained therethrough and application of product

A technology for inhibiting protein and aqueous solutions, applied in the fields of application, protein food processing, protein food ingredients, etc., can solve the problems of application limitations, achieve the effects of protein molecular configuration stability, surface activity retention, and foaming improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

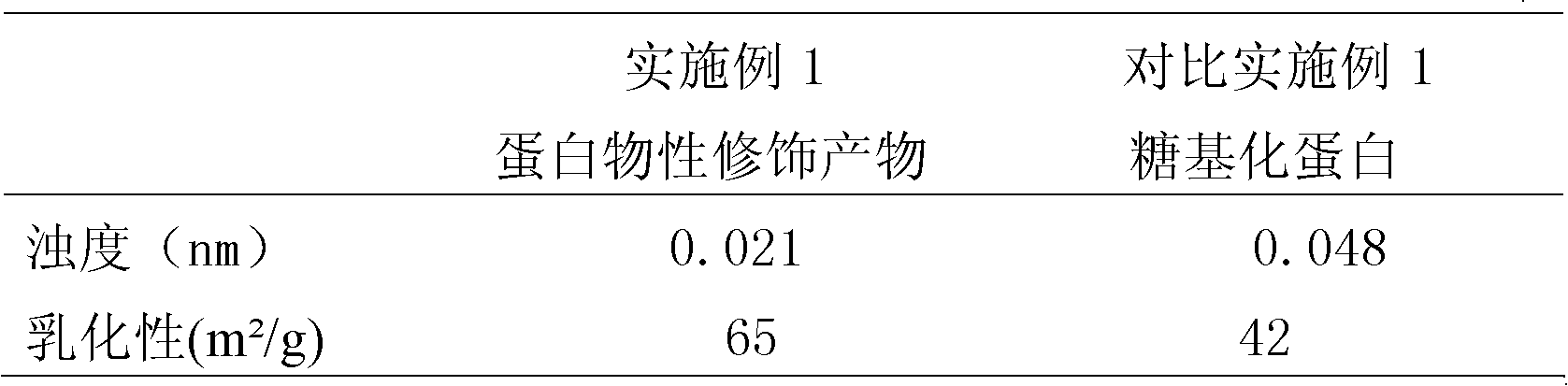

Embodiment 1

[0030] Accurately weigh 0.5g of soybean 7S globulin, dissolve it in 10mL of 0.01mol / L sodium phosphate buffer solution with pH 6.5, weigh 1.5g of dextran and 1.5g of polyethylene glycol (PEG3000) into the buffer and mix evenly. React in a constant temperature magnetic stirrer at 95°C for 6h. After the reaction, quickly cool to room temperature (25°C) in an ice bath to terminate the reaction. The product is centrifuged at 5000rpm for 20min and dialyzed at 4°C for 48h to remove the inert crowding reagent polyethylene glycol and other small particles. Molecular matter. The product is freeze-dried to obtain a product with modified protein properties.

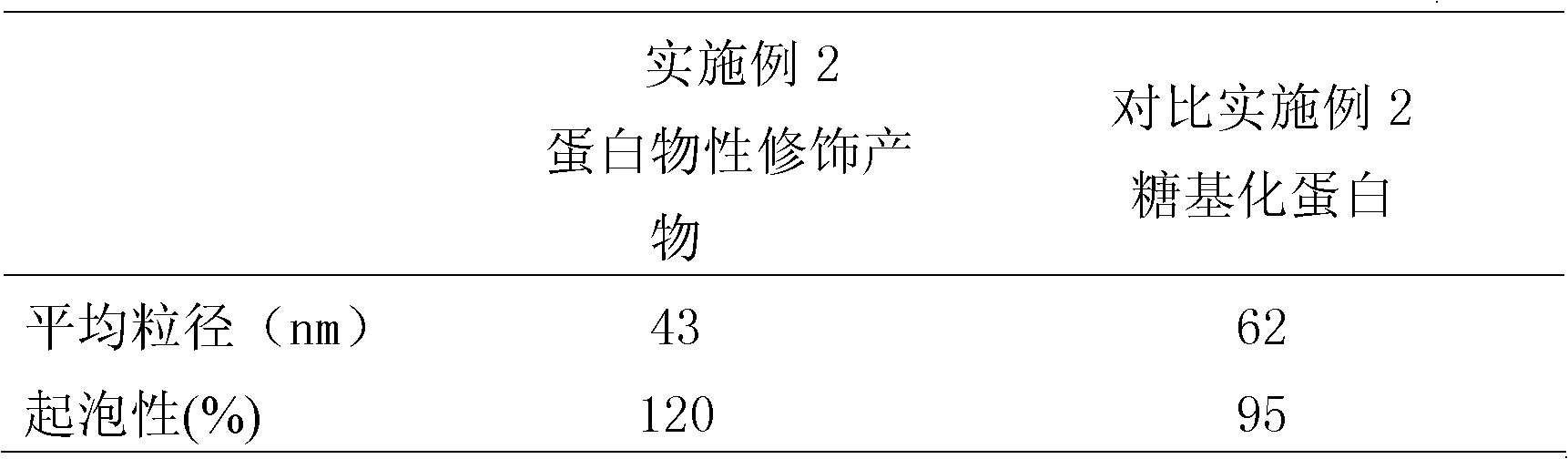

Embodiment 2

[0038] Accurately weigh 0.1g of soybean 7S globulin, dissolve it in 10mL of 0.01mol / L sodium phosphate buffer solution with pH 6, weigh 0.5g of dextran and 1.5g of polyethylene glycol (PEG2000) into the buffer and mix well, React in a constant temperature magnetic stirrer at 80°C for 10 hours. After the reaction is completed, quickly cool to room temperature (25°C) in an ice bath to terminate the reaction. The product is centrifuged at 4000 rpm for 30 minutes and dialyzed at 4°C for 24 hours to remove the inert crowding reagent polyethylene glycol and other small particles. Molecular matter. The product is freeze-dried to obtain a product with modified protein properties.

Embodiment 3

[0045] Accurately weigh 0.6g soybean protein isolate, dissolve it in 20mL 0.01mol / L sodium phosphate buffer solution with pH 8, weigh 3g carrageenan and 5g polyethylene glycol (PEG3350) and add them to the buffer, mix well, and stir magnetically at constant temperature The reaction was carried out at 60°C for 30 hours. After the reaction was completed, the reaction was quickly cooled to room temperature (25°C) in an ice bath to terminate the reaction. The product was centrifuged at 4000 rpm for 30 minutes and dialyzed at 4°C for 30 hours to remove the inert crowding agent polyethylene glycol and other small molecules. The product is freeze-dried to obtain a product with modified protein properties. After purification, the product is used as a new type of emulsifier in meat products such as ham sausage, which can produce better emulsification and thermal stability than ordinary soybean protein isolate, making the flavor and taste of ham sausage better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com