A ceramic filter element, its preparation method and application

A ceramic filter element and filter element technology, applied in the field of water purification, can solve the problems of long sintering time of green body, increased energy consumption, and increased process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

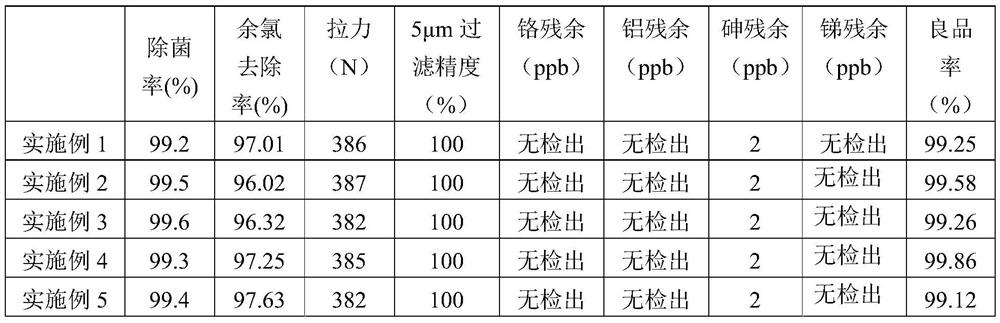

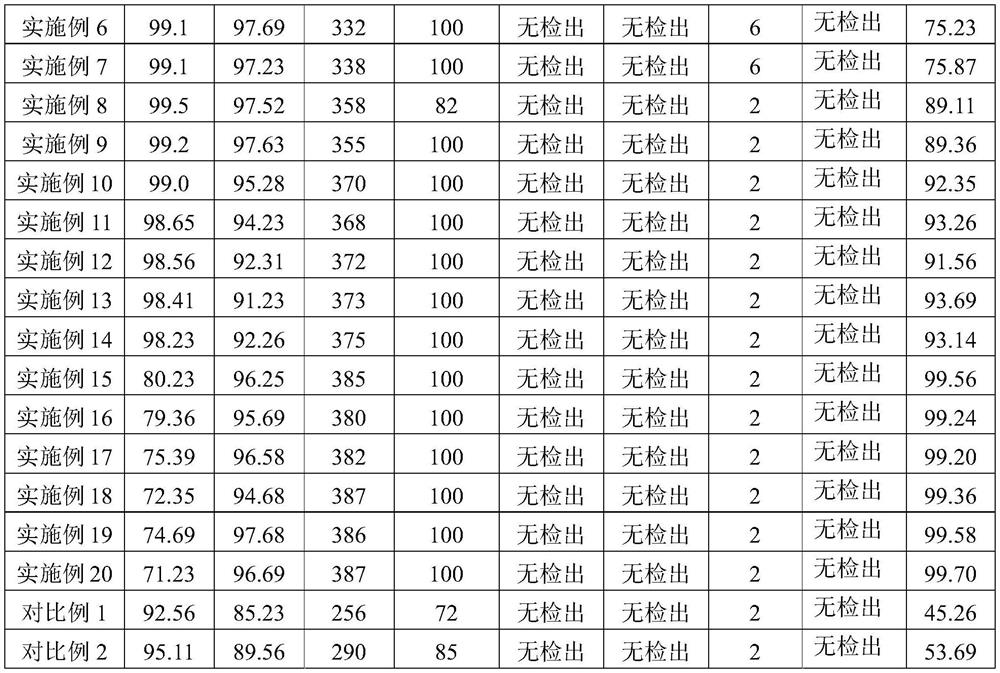

Examples

Embodiment 1

[0055] In this embodiment, a method for preparing a ceramic filter element is provided, and the method for preparing a ceramic filter element includes the following steps:

[0056] (1) 80 parts by weight of 200 mesh diatomite, 5 parts by weight of silver-loaded titanium dioxide, 5 parts by weight of titanium dioxide and 10 parts by weight of Na 2 O 3SiO 2 Mix under stirring for 10 minutes, and then carry out carbon dioxide air-curing molding under the conditions of carbon dioxide purity of 99% and blowing pressure of 0.5 MPa to obtain a green filter element;

[0057] (2) Divide the filter element green body obtained in step (1) into six sections for sintering according to the sintering temperature. In the first section, the sintering temperature is raised from 25°C to 110°C at a heating rate of 1°C / min, and kept for 2 hours. In the first stage, the sintering temperature is raised from 110°C to 350°C at a rate of 1°C / min, and held for 1 hour; in the third stage, the sintering ...

Embodiment 2

[0059] (1) 70 parts by weight of 100 mesh diatomite, 10 parts by weight of silver-loaded titanium dioxide, 5 parts by weight of titanium dioxide and 15 parts by weight of Na 2 O SiO 2 Mix under stirring for 10 minutes, and then carry out carbon dioxide air-hardening method under the conditions of carbon dioxide purity of 90% and blowing pressure of 1 MPa to obtain a green filter element;

[0060] (2) Divide the filter element green body obtained in step (1) into six sections for sintering according to the sintering temperature. In the first section, the sintering temperature is raised from 25°C to 110°C at a heating rate of 5°C / min, and kept for 2 hours. In the first stage, the sintering temperature was raised from 110°C to 350°C at a rate of 5°C / min, and held for 2 hours; in the third stage, the sintering temperature was raised from 350°C to 780°C at a rate of 5°C / min, and held for 2 hours The first stage raises the sintering temperature from 780°C to 1100°C at a heating rat...

Embodiment 3

[0062] (1) 70 parts by weight of 200 mesh diatomite, 10 parts by weight of silver-loaded titanium dioxide, 5 parts by weight of titanium dioxide and 15 parts by weight of 3Na 2 O SiO 2 Mix under stirring for 10 minutes, and then carry out carbon dioxide air-curing molding under the conditions of carbon dioxide purity of 60% and blowing pressure of 0.1 MPa to obtain a green filter element;

[0063] (2) Divide the filter element green body obtained in step (1) into six sections for sintering according to the sintering temperature. In the first section, the sintering temperature is raised from 25°C to 110°C at a heating rate of 15°C / min, and kept for 2 hours. The first stage raises the sintering temperature from 110°C to 350°C at a heating rate of 15°C / min, and keeps it for 1 hour. The first stage raises the sintering temperature from 780°C to 1100°C at a heating rate of 15°C / min, and keeps it for 5 hours. The sintering temperature was lowered from 500°C to 80°C at a heating ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com