Method for preparing needle-like yttrium oxide

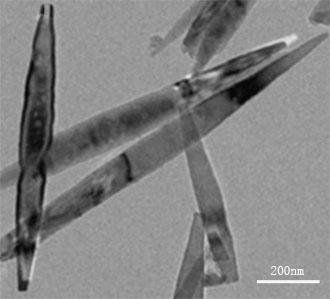

A needle-shaped yttrium oxide technology, which is applied in the field of preparation of needle-shaped yttrium oxide, can solve the problems such as the preparation method of dispersive needle-shaped yttrium oxide, and achieve the effect of unique shape, easy operation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of acicular yttrium oxide, comprising the steps of:

[0027] (1) Take yttrium nitrate or yttrium chloride, prepare yttrium salt solution with a concentration of 0.1mol / L with deionized water, take ammonium carbonate and prepare an alkali solution with a concentration of 0.1mol / L with deionized water, and take complex Disodium ethylenediamine tetraacetate is mixed with deionized water to be the complexing agent solution that concentration is 0.05mol / L;

[0028] (2) Slowly add the complexing agent solution obtained in step (1) into the yttrium salt solution, and react in a water bath at 40°C for 3 hours while stirring slowly to obtain the first intermediate product, wherein the moles of the complexing agent The amount is 0.1 times the molar amount of yttrium ion;

[0029] (3) Add the first intermediate product and the alkali solution obtained in step (1) into the hydrothermal reaction kettle, control the molar ratio of yttrium ion to ammonium carbona...

Embodiment 2

[0033] A preparation method of acicular yttrium oxide, comprising the steps of:

[0034] (1) Take yttrium nitrate or yttrium chloride, and prepare an yttrium salt solution with a concentration of 0.05mol / L with deionized water, and prepare an alkali solution with a concentration of 0.1mol / L with ammonium bicarbonate and deionized water, and take the Mixture disodium edetate is mixed with deionized water to be the complexing agent solution that concentration is 0.02mol / L;

[0035] (2) Slowly add the complexing agent solution obtained in step (1) dropwise into the yttrium salt solution, and react in a water bath at 60°C for 1.5 hours while stirring slowly to obtain the first intermediate product, in which the complexing agent The molar weight is 0.5 times the molar weight of yttrium ion;

[0036] (3) Add the first intermediate product and the alkali solution obtained in step (1) to the hydrothermal reaction kettle, control the molar ratio of yttrium ion to ammonium bicarbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com