A kind of encapsulation method and encapsulation structure

A packaging material and a part of the technology, applied in the field of a method and the packaging structure using this method, can solve the problems of wet process implementation obstacles, wet process complexity, danger, etc., achieve a firm and stable packaging structure, and avoid packaging Ineffectiveness, the effect of strengthening the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

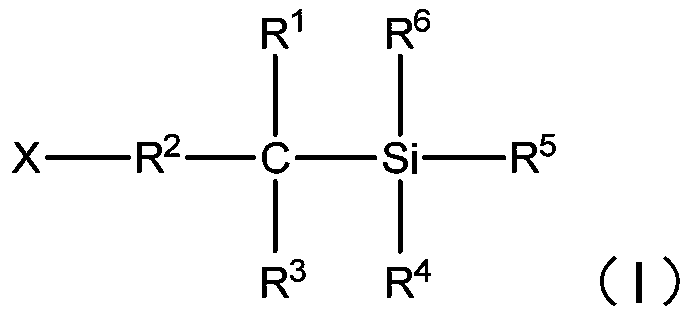

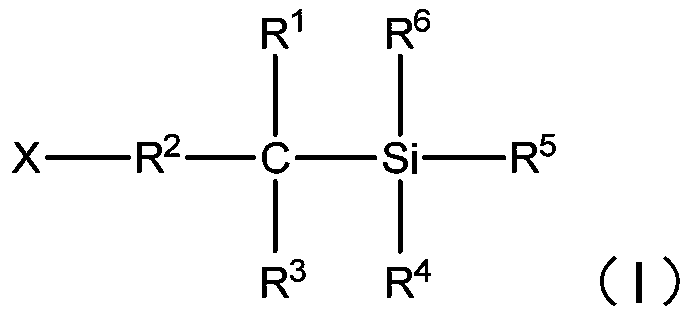

[0037] The specific embodiment of the present invention comprises the following steps:

[0038] S1: Send the semiconductor substrate sample into the vacuum chamber, expose at least a part of the surface of the substrate, turn on the vacuum system, pump the vacuum chamber to the back pressure, and make the vacuum degree of the backside 0.1-10000Pa; as a preference, the backside vacuum The degree is 1-100Pa. This step can provide a clean process environment for subsequent processes.

[0039] S2: Activation and cleaning of the substrate surface: the gas used for plasma activation is introduced into the vacuum chamber, specifically, it may contain oxygen, nitrogen, carbon monoxide, carbon dioxide, hydrogen, argon or helium, and preferably contains oxygen or argon. At the same time, turn on the radio frequency power supply, the radio frequency power is 10-10000W, the pulse voltage frequency is 1-10000Hz, and the duty cycle is 1-100%; as a preference, the radio frequency power is ...

Embodiment 1

[0058] S1: After the substrate (polyimide substrate) is sent into the vacuum chamber, the vacuum system is turned on, and the vacuum chamber is pumped to the back pressure, so that the vacuum degree of the back of the vacuum chamber is 100Pa, providing a clean process for the subsequent process environment.

[0059] S2: Plasma activation: Oxygen is introduced into the vacuum chamber; at the same time, the radio frequency power supply is turned on, the radio frequency power is 800W, the pulse voltage frequency is 150Hz, and the duty cycle is 50%; plasma is generated by excitation.

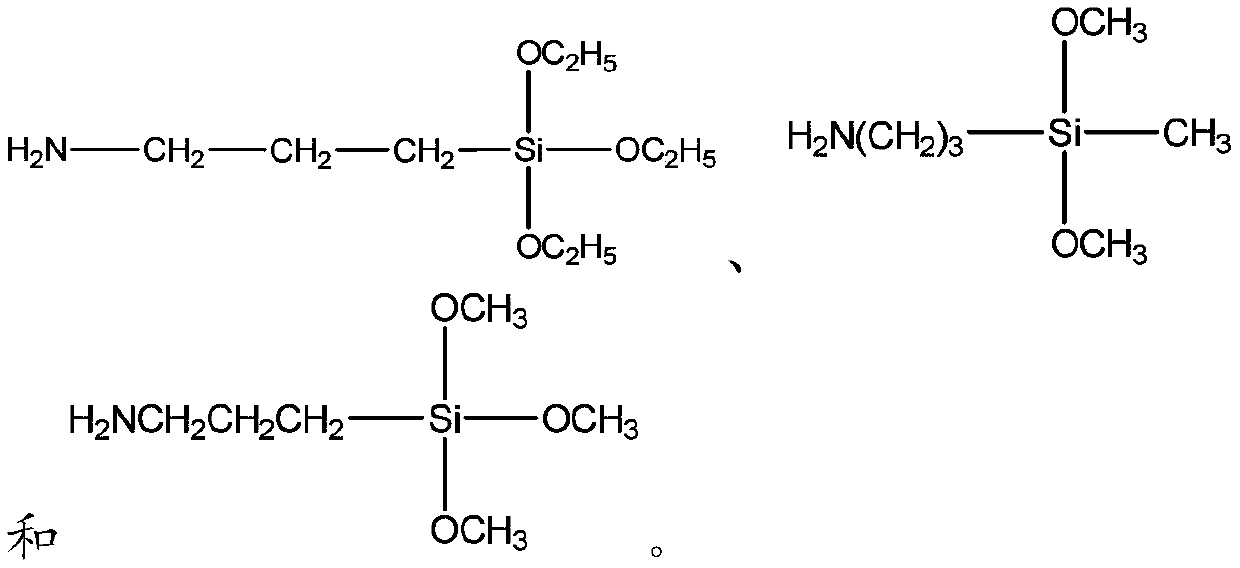

[0060] S3: Plasma deposition: the following chemicals (compound 1) are introduced into the plasma chamber:

[0061]

[0062] After the gas flow is stable, when the pressure is stabilized in the range of 1-10000T, turn on the radio frequency plasma, the radio frequency power is 7000W, the pulse frequency is 500KHz, the pulse voltage frequency is 1000KHz, and the duty cycle is 50%. Through the abov...

Embodiment 2

[0065]S1: After sending the orthosilicate coated substrate (TEOS coated substrate) into the vacuum chamber, the vacuum system is turned on, and the vacuum chamber is pumped to the back pressure, so that the vacuum degree of the back of the vacuum chamber is 50Pa, which is for the subsequent Process provides a clean process environment.

[0066] S2: Plasma activation: argon gas is introduced into the vacuum chamber; at the same time, the radio frequency power supply is turned on, the radio frequency power is 50W, the pulse voltage frequency is 100Hz, and the duty cycle is 80%, to generate plasma.

[0067] S3: Plasma deposition: the following chemicals (compound 2) are introduced into the plasma chamber:

[0068]

[0069] After the gas flow is stable, when the pressure is stable within the range of 1-10000T, turn on the radio frequency plasma, the radio frequency power is 2000W, the pulse frequency is 200KHz, the pulse voltage frequency is 300KHz, and the duty cycle is 15%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com