A method for preparing high-performance graphene by a multi-step weak oxidation-reduction method

A weak oxidation and reduction technology, which is applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of complex preparation process, harsh conditions, and high energy consumption, so as to improve preparation efficiency, improve dispersibility, and good compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

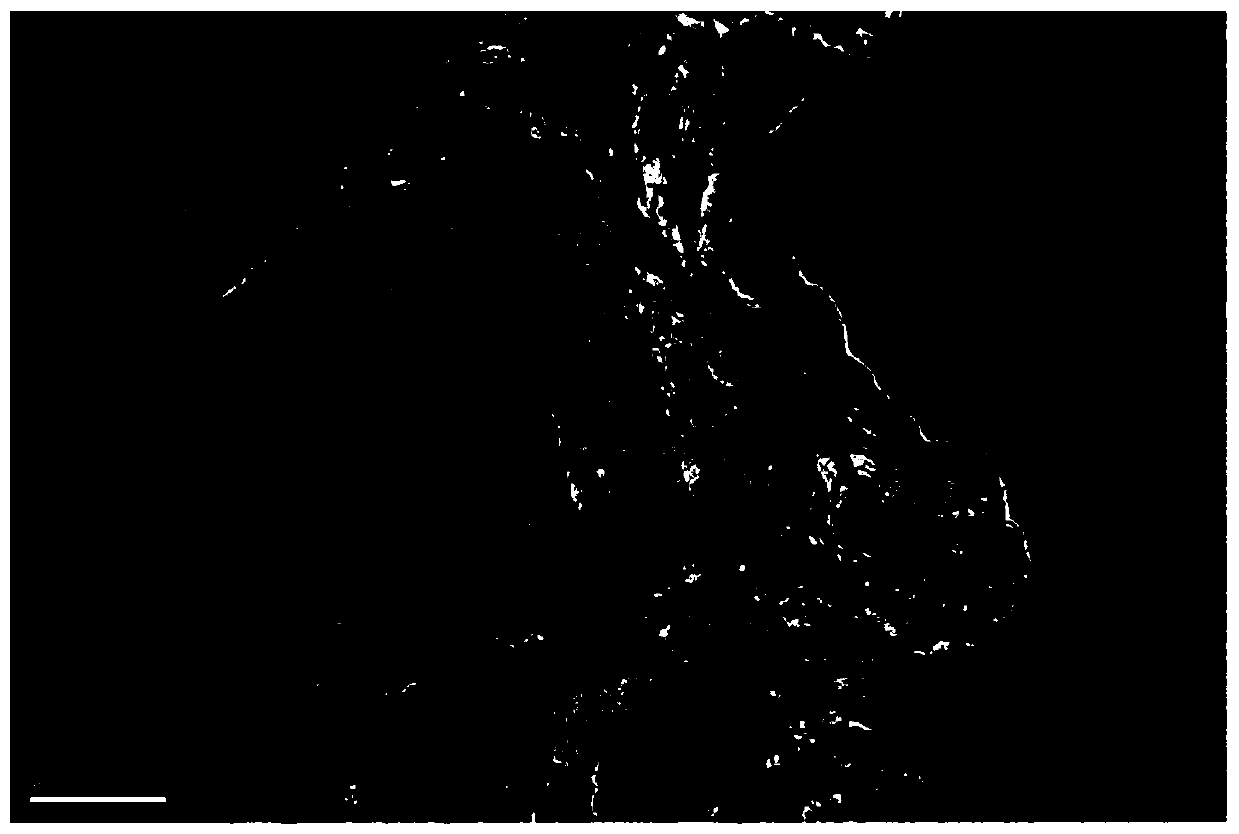

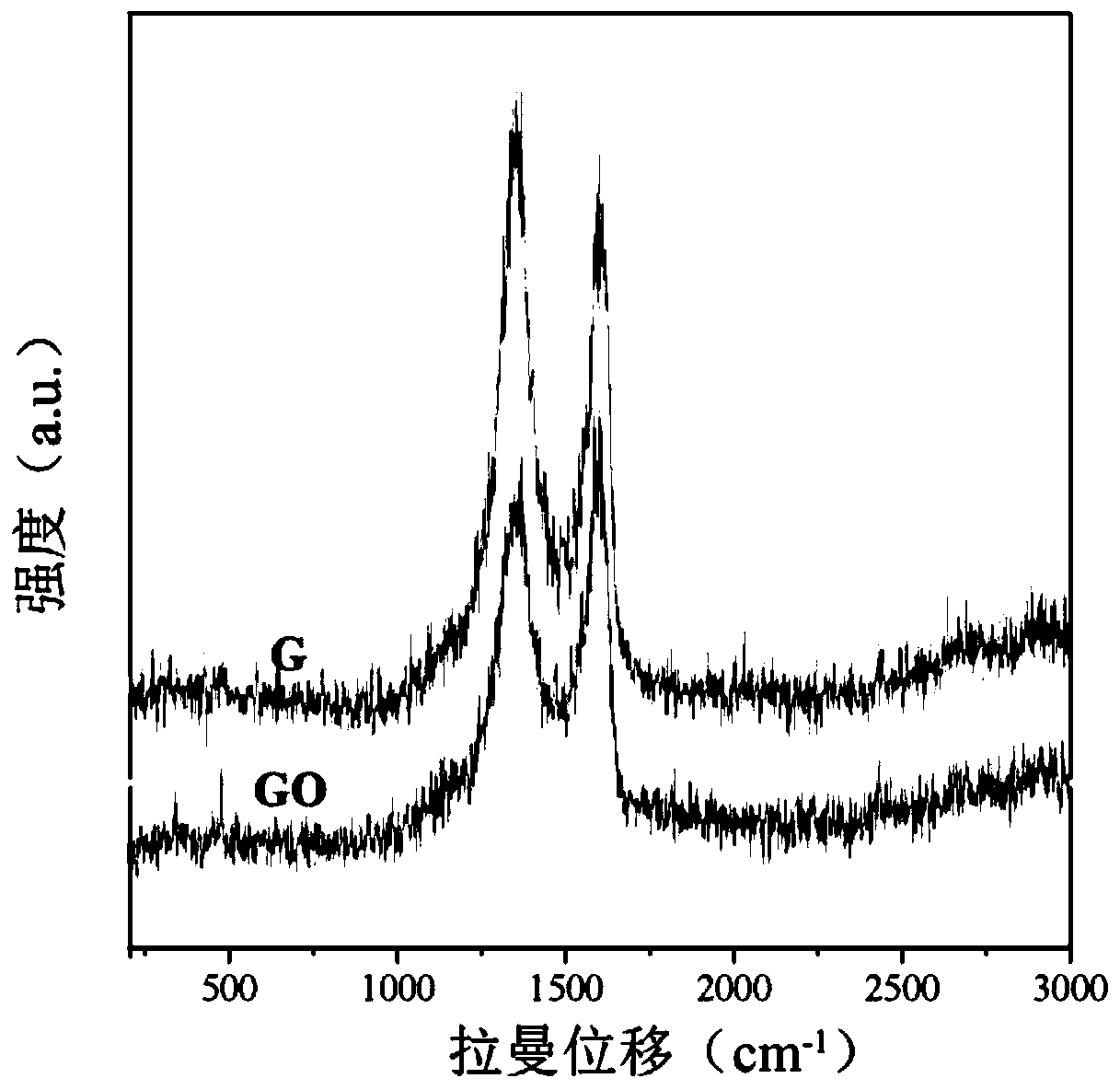

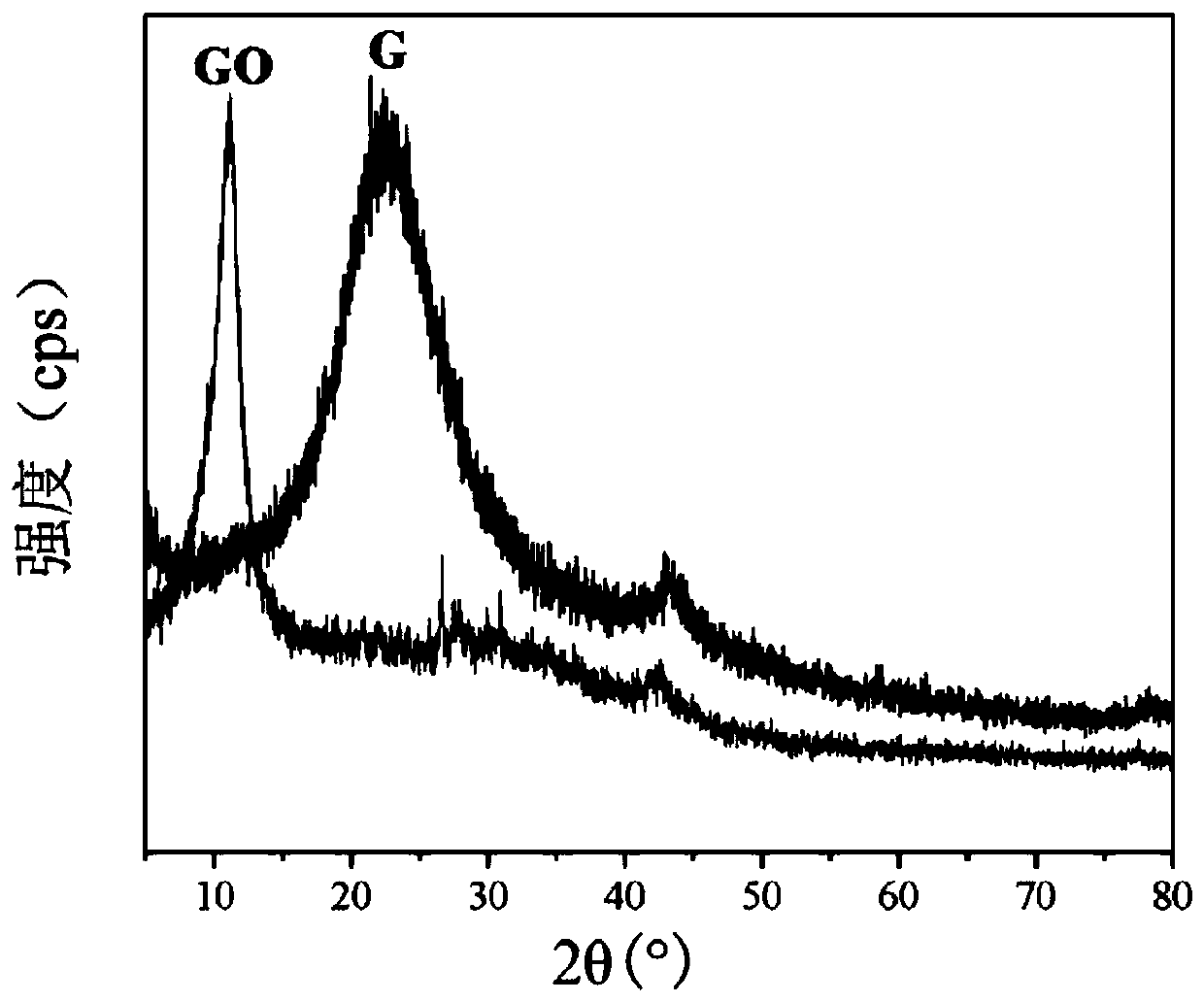

Image

Examples

Embodiment 1

[0038] A method for preparing high-performance graphene by a multi-step weak oxidation-reduction method, the steps are as follows:

[0039] 1) After ball milling 10 g of flake graphite for 4 hours, put it into a mixed solution of 50 g of 10% acetic acid solution and 50 g of 30% hydrogen peroxide solution, and soak in airtight at room temperature for 12 hours;

[0040] 2) Add a mixture of 1 g of ammonium nitrate and ammonium persulfate to the solution obtained after airtight immersion in step 1), the mass ratio of ammonium nitrate and ammonium persulfate is 10:1, stir evenly and put it into a high-pressure closed hydrothermal kettle , 150°C for 6 hours;

[0041] 3) Cool the mixed solution after the intercalation treatment in step 2) to room temperature, add deionized water, and use a pressure of 15 MPa to subject the mixed solution to high-pressure treatment, and then perform ultrasonic stripping treatment for 3 hours, and the ultrasonic power is 800W;

[0042] 4) The mixed so...

Embodiment 2

[0053] A method for preparing high-performance graphene by a multi-step weak oxidation-reduction method, the steps are as follows:

[0054] 1) After ball milling 5g of flake graphite for 3 hours, put it into a mixed solution of 10g of 8% acetic acid solution and 30g of 25% hydrogen peroxide solution, and soak for 8 hours at room temperature;

[0055] 2) Add a mixture of 0.5 g of ammonium nitrate and ammonium persulfate to the solution obtained after airtight soaking in step 1), the mass ratio of ammonium nitrate and ammonium persulfate is 8:1, stir well and put it into a high-pressure airtight hydrothermal kettle medium, 120°C for 4 hours;

[0056] 3) Cool the mixed solution after the intercalation treatment in step 2) to room temperature, add deionized water, and use a pressure of 12 MPa to perform high-pressure treatment on the mixed solution, and then perform ultrasonic stripping treatment for 1 hour, and the ultrasonic power is 1000W;

[0057] 4) The mixed solution after ...

Embodiment 3

[0062] A method for preparing high-performance graphene by a multi-step weak oxidation-reduction method, the steps are as follows:

[0063] 1) After ball milling 20g of flake graphite for 4 hours, put it into a mixed solution of 50g of 15% acetic acid solution and 150g of 20% hydrogen peroxide solution, and soak for 14 hours at room temperature;

[0064] 2) Add a mixture of 1 g of ammonium nitrate and ammonium persulfate to the solution obtained after airtight soaking in step 1), the mass ratio of ammonium nitrate and ammonium persulfate is 9:1, stir evenly and put it into a high-pressure closed hydrothermal kettle , 140°C for 5 hours;

[0065] 3) Cool the mixed solution after the intercalation treatment in step 2) to room temperature, add deionized water, and use a pressure of 14MPa to subject the mixed solution to high-pressure treatment, and then perform ultrasonic stripping treatment for 4 hours, and the ultrasonic power is 1200W;

[0066] 4) The mixed solution after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com