Preparation method of corrosion-resistant high-strength metal fiber felt

A technology of metal fiber felt and metal fiber, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problem of mechanical quality of metal fiber felt, poor corrosion resistance, short service life and instability, and poor filtration accuracy High-level problems, to achieve the effect of easy large-scale promotion and application, good mechanical quality, and process specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

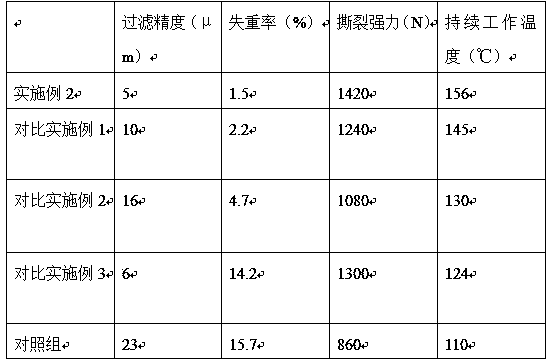

Examples

Embodiment 1

[0031] A method for preparing a corrosion-resistant high-strength metal fiber felt, comprising the steps of:

[0032] (1) Metal fiber preparation:

[0033] Metal fibers or metal alloys are made into metal fibers after cluster drawing processing, and then the metal fibers are cut into short lengths to make chopped metal fibers for use;

[0034] (2) Preparation of semi-finished metal fiber felt:

[0035] According to the requirements of filtration accuracy, mix the chopped metal fibers prepared in step (1) through the felting machine cloth method to make a single-layer loose and porous metal fiber felt, and then mix the above-mentioned single-layer metal fiber felt according to the requirements After one or more layers of superimposed processing, the semi-finished metal fiber felt is obtained for use;

[0036] (3) Sintering treatment:

[0037] Put the semi-finished metal fiber mat obtained in step (2) into a constant temperature box for preheating treatment, and perform ultra...

Embodiment 2

[0053] A method for preparing a corrosion-resistant high-strength metal fiber felt, comprising the steps of:

[0054] (1) Metal fiber preparation:

[0055] Metal fibers or metal alloys are made into metal fibers after cluster drawing processing, and then the metal fibers are cut into short lengths to make chopped metal fibers for use;

[0056] (2) Preparation of semi-finished metal fiber felt:

[0057] According to the requirements of filtration accuracy, the chopped metal fibers obtained in step (1) are mixed through the felting machine to make a single-layer loose and porous metal fiber felt, and then the above-mentioned single-layer metal fiber felt is mixed according to the requirements. After one or more layers of superimposed processing, the semi-finished metal fiber felt is obtained for use;

[0058] (3) Sintering treatment:

[0059] Put the semi-finished metal fiber mat obtained in step (2) into a constant temperature box for preheating treatment, and perform ultras...

Embodiment 3

[0075] A method for preparing a corrosion-resistant high-strength metal fiber felt, comprising the steps of:

[0076] (1) Metal fiber preparation:

[0077] Metal fibers or metal alloys are made into metal fibers after cluster drawing processing, and then the metal fibers are cut into short lengths to make chopped metal fibers for use;

[0078] (2) Preparation of semi-finished metal fiber felt:

[0079] According to the requirements of filtration accuracy, the chopped metal fibers obtained in step (1) are mixed through the felting machine to make a single-layer loose and porous metal fiber felt, and then the above-mentioned single-layer metal fiber felt is mixed according to the requirements. After one or more layers of superimposed processing, the semi-finished metal fiber felt is obtained for use;

[0080] (3) Sintering treatment:

[0081] Put the semi-finished metal fiber felt obtained in step (2) into a constant temperature box for preheating treatment, and perform ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com