High tenacity polyester yarns

a high-tenacity, polyester technology, applied in the direction of yarn, monocomponent polyester artificial filament, transportation and packaging, etc., can solve the problems of poor uniformity, inability to achieve the effect of high-tenacity polyester yarns, and high cost of employing means to obtain polymers with iv of 0.7 and above,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

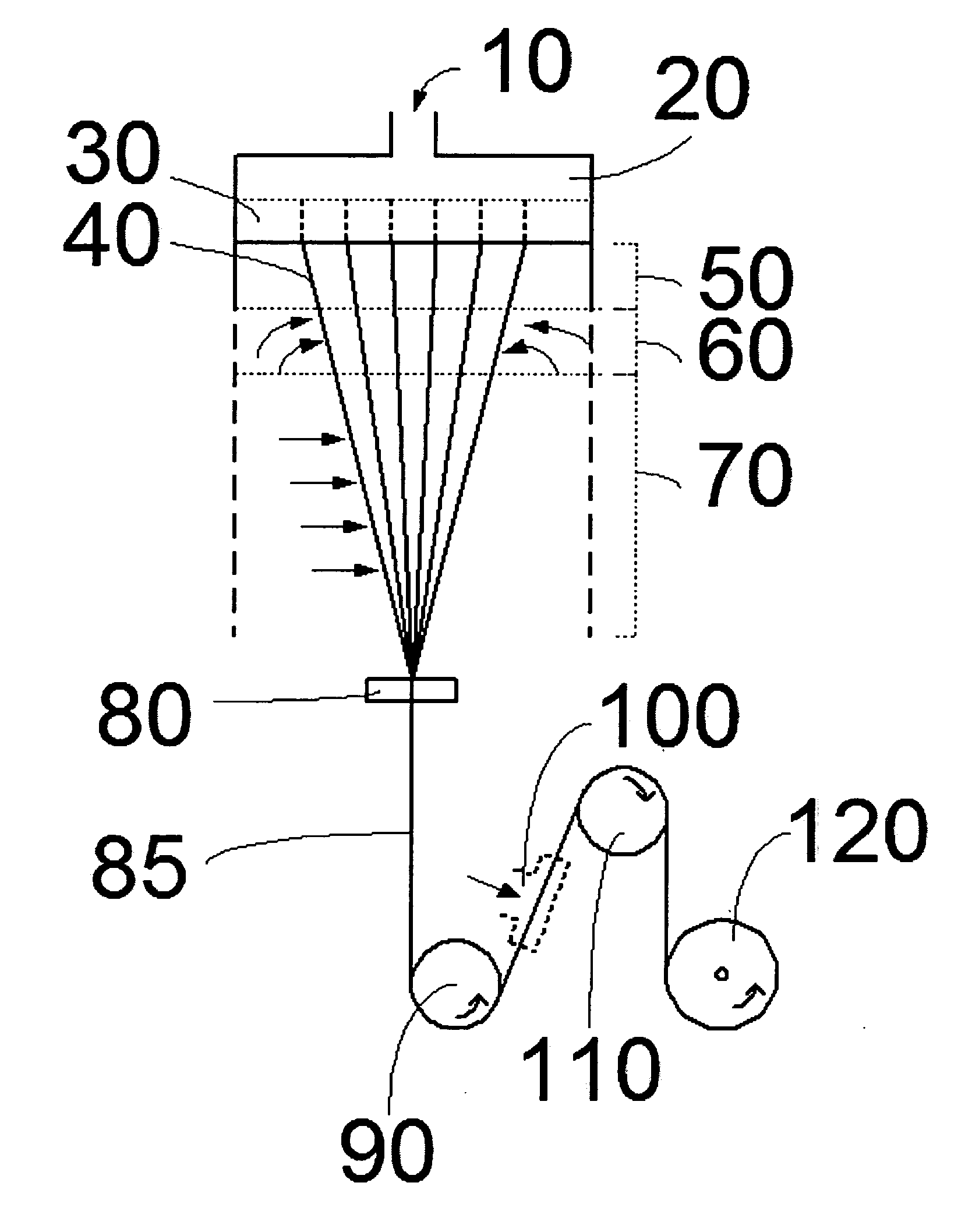

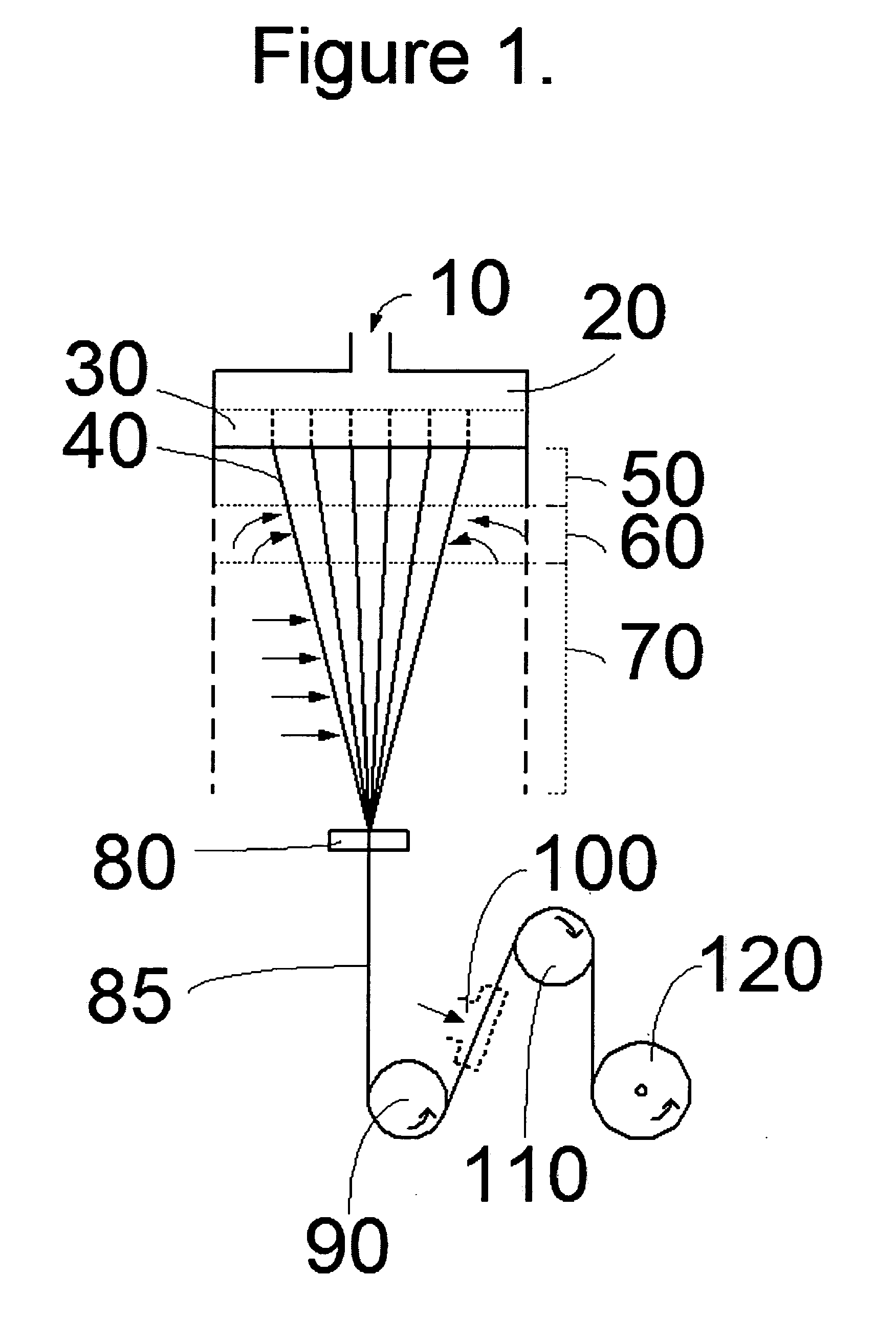

[0036] In this example two POY samples of the invention were made. Sample A is a 34 filament and 148 denier yarn which was prepared using the apparatus and process schematically represented in FIG. 1. Sample B is a 34 filament 305 denier yarn prepared using the same apparatus and process. Both samples A and B were produced from polyethylene terephthalate polymer containing about 120 ppm chain brancher (trimethyl trimellitate). This polymer had an LRV of about 20.8. The hybrid quench portion of the apparatus of FIG. 1 had a quench delay 50 of about 5 inches (12.7 cm) and a radial quench zone of about 4 inches (10.1 cm) and a take-up roll 120 speed set to obtain an elongation at break of about 150% (in the range of 3000 to 3200 meters per minute). The properties obtained for these two invention samples of POY are shown in Table 1. Included in Table 1 are the properties of 5 comparative POY samples of the prior art which are commercially available. The invention samples, POY A and POY ...

example 2

[0037] In this example two POY samples of the invention were made. Sample C is a 34 filament and 148 denier yarn which was prepared using the apparatus and process schematically represented in FIG. 1. Sample D is a 34 filament 305 denier yarn prepared using the same apparatus and process. Both samples C and D were produced from polyethylene terephthalate polymer containing about 120 ppm chain brancher (trimethyl trimellitate). This polymer had an LRV of about 25; a higher LRV than used in Example 1. The hybrid quench portion of the apparatus of FIG. 1 had a quench delay 50 of about 5 inches (12.7 cm) and a radial quench zone of about 4 inches (10.1 cm) and a take-up roll 120 speed set to obtain an elongation at break of about 150% (in the range of 2950 to 3000 meters per minute). The properties of these two invention samples of POY obtained are shown in Table 2.

TABLE 2# ofTake-upfila-speedTBEBTBNYarnDeniermentsLRV(mpm)(g / den)(%)(g / den)Sample C1483426.830007.28152.96.02Sample D3053...

example 3

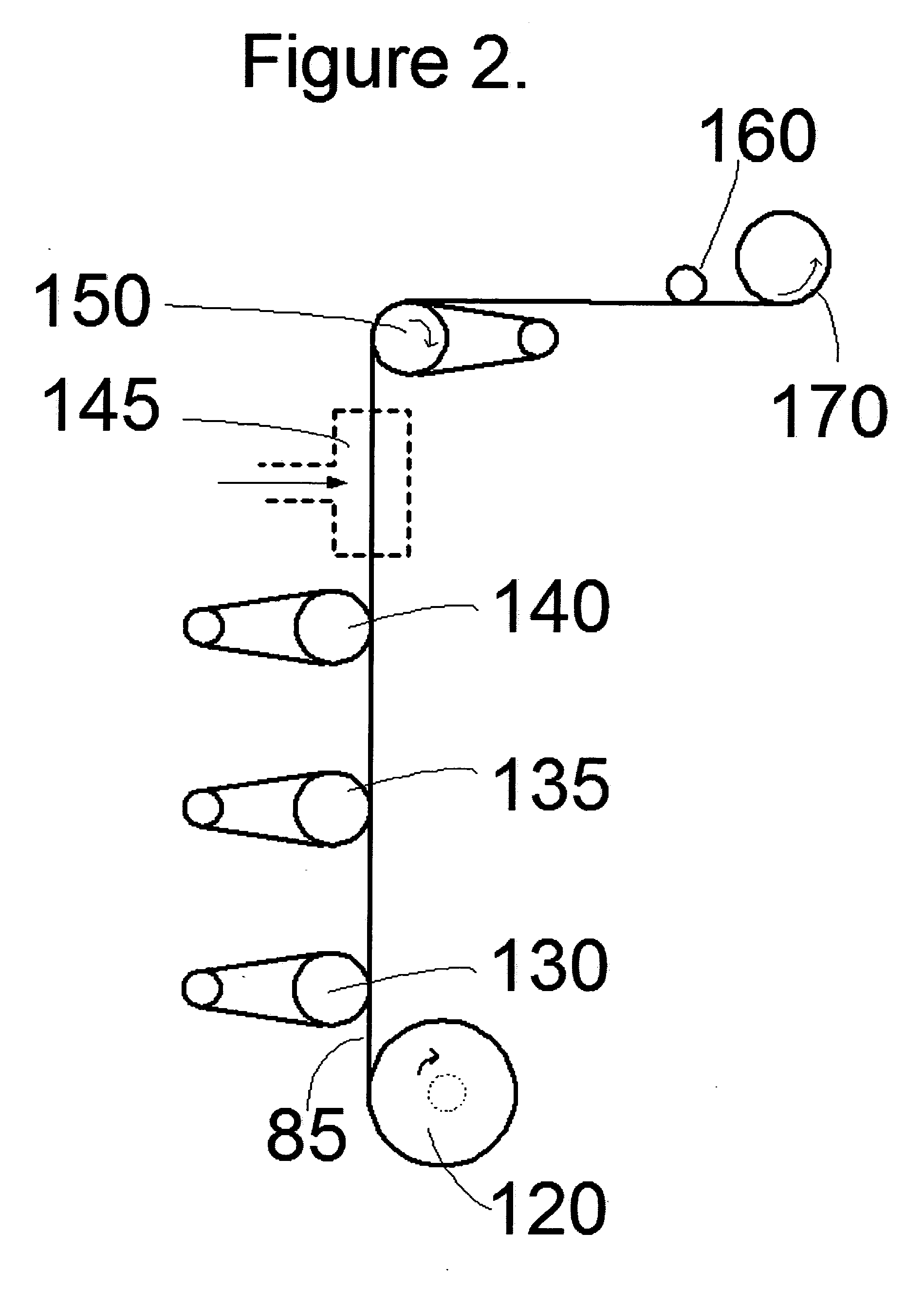

[0038] In this example the POY samples of the invention from both Examples 1 and 2 and the commercially available comparative yarns of the prior art were drawn using the apparatus and process schematically represented in FIG. 2. The drawn multifilament were prepared using a speed of 750 meters per minute for godet 140, a temperature of 80° C. for godet 135 and a temperature of 190° C. for godet 140. Shown in Table 3. are the total draw ratio, the relaxation ratio, the tenacity and elongation properties, along with the toughness factor TF for the yarns obtained.

TABLE 3TotalDrawRelaxationTenacityEBBOSYarnRatioRatio(g / den)(%)TF(%)Sample A2.450.9178.1013.820.71.3inventionComparative 12.100.9177.5314.314.40.7Comparative 22.100.9177.4812.016.11.0Comparative 32.150.9177.2613.416.71.0Sample B2.350.9007.5617.318.80.3inventionComparative 42.150.9316.8116.215.80.7Comparative 52.100.8906.9714.914.80.5Sample C2.350.9108.8115.521.81.6inventionSample D2.350.8978.2117.220.30.7invention

[0039] As b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com