Heat-conducting structure of aluminum alloy-inlaid graphene-based composite substrate and manufacturing method of heat-conducting structure

A composite material, graphene-based technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of low longitudinal thermal conductivity of graphene-based heat dissipation materials and limit the comprehensive heat dissipation capacity, so as to improve heat transfer efficiency, expand application scope, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

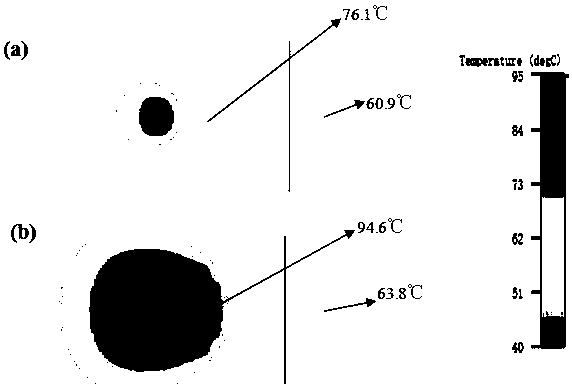

Embodiment 1

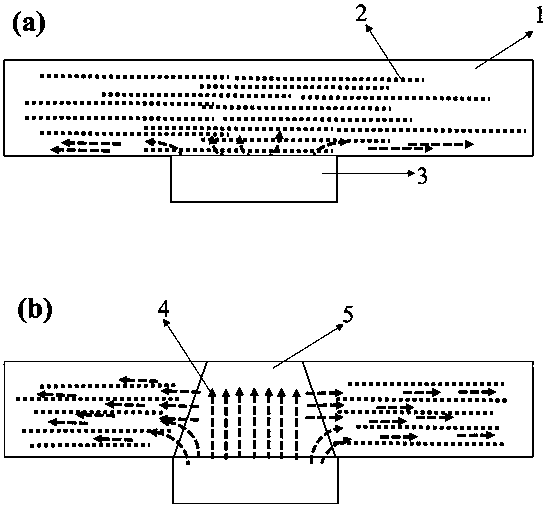

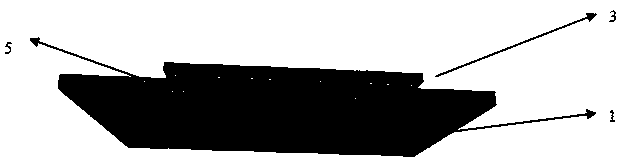

[0035] This embodiment provides a method for manufacturing an aluminum alloy inlaid in a graphene-based composite material substrate, and the specific implementation steps are as follows:

[0036]1) Select a graphene-based composite material with an area of 200×150mm and a thickness of 10mm. In this composite material, graphene accounts for 90v%, copper accounts for 10v%, and the graphene is oriented along the XY plane direction, and the plane heat of the substrate The conductivity is ~1200W / (m.K), and the vertical thermal conductivity is ~5W / (m.K). Using a CNC machine tool and a milling cutter, drill a through hole with a trapezoidal side section on the graphene-based composite material substrate. The height of the hole is the same as the thickness of the substrate. The size of the upper surface of the hole is 15×15mm, and the size of the lower surface is 20mm. ×20mm, the position of the hole is in the middle of the graphene substrate.

[0037] 2) Preparation of aluminum a...

Embodiment 2

[0044] This embodiment provides a method for manufacturing an aluminum alloy inlaid in a graphene-based composite material substrate, and the specific implementation steps are as follows:

[0045] 1) Select a graphene composite substrate with an area of 200×150mm and a thickness of 10mm. The material contains 15v% copper and the rest is graphene. The graphene is oriented along the XY plane direction, and the plane thermal conductivity of the substrate is ~1100W / (m.K), the vertical thermal conductivity is ~5~7W / (m.K). Using a CNC machine tool and a milling cutter, drill two holes with a trapezoidal side section on the graphene-based composite material substrate. The height of the holes is the same as the thickness of the substrate. The size of the upper surface of the other hole is 10×10mm, and the size of the lower surface is 25×25mm.

[0046] 2) Preparation of aluminum alloy blocks: 6061 aluminum material is selected, and the aluminum alloy blocks are prepared by wire-cutt...

Embodiment 3

[0052] This embodiment provides a method for manufacturing an aluminum alloy inlaid in a graphene-based composite material substrate, and the specific implementation steps are as follows:

[0053] 1) Select a graphene / carbon composite substrate with an area of 200×200mm and a thickness of 5mm, in which the graphene volume fraction is 90%, the carbon nanotube volume content is 10%, and the graphene is oriented along the XY plane direction. And the plane thermal conductivity of the substrate is ~1300W / (m.K), and the vertical thermal conductivity is ~3~6W / (m.K). Using a CNC machine tool and a milling cutter, a through-hole with a trapezoidal side section is drilled on the graphene-based composite substrate. The size of the upper surface of the hole is 15×15mm, and the size of the lower surface is 20×20mm.

[0054] 2) Preparation of aluminum alloy blocks: 6061 aluminum material is selected, and the aluminum alloy blocks are prepared by wire-cutting of CNC machine tools. A margin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com