Brushless motor

A brushless motor and component technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as hidden dangers of motor safety, fan blade falling off, fan blade axial displacement, etc., to improve work stability, prevent falling off, Avoid the effect of axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present application will be further elaborated below in conjunction with the accompanying drawings and embodiments.

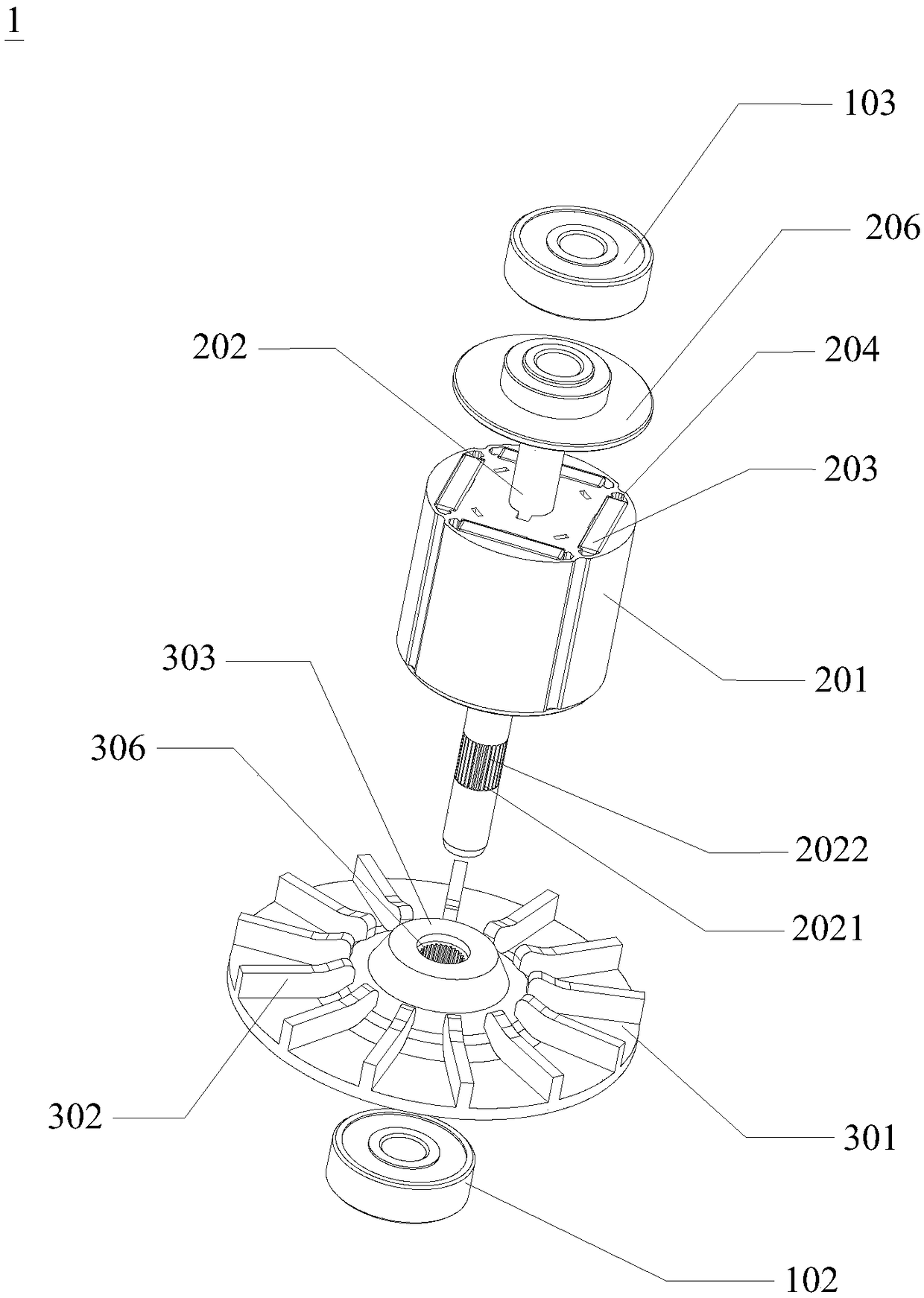

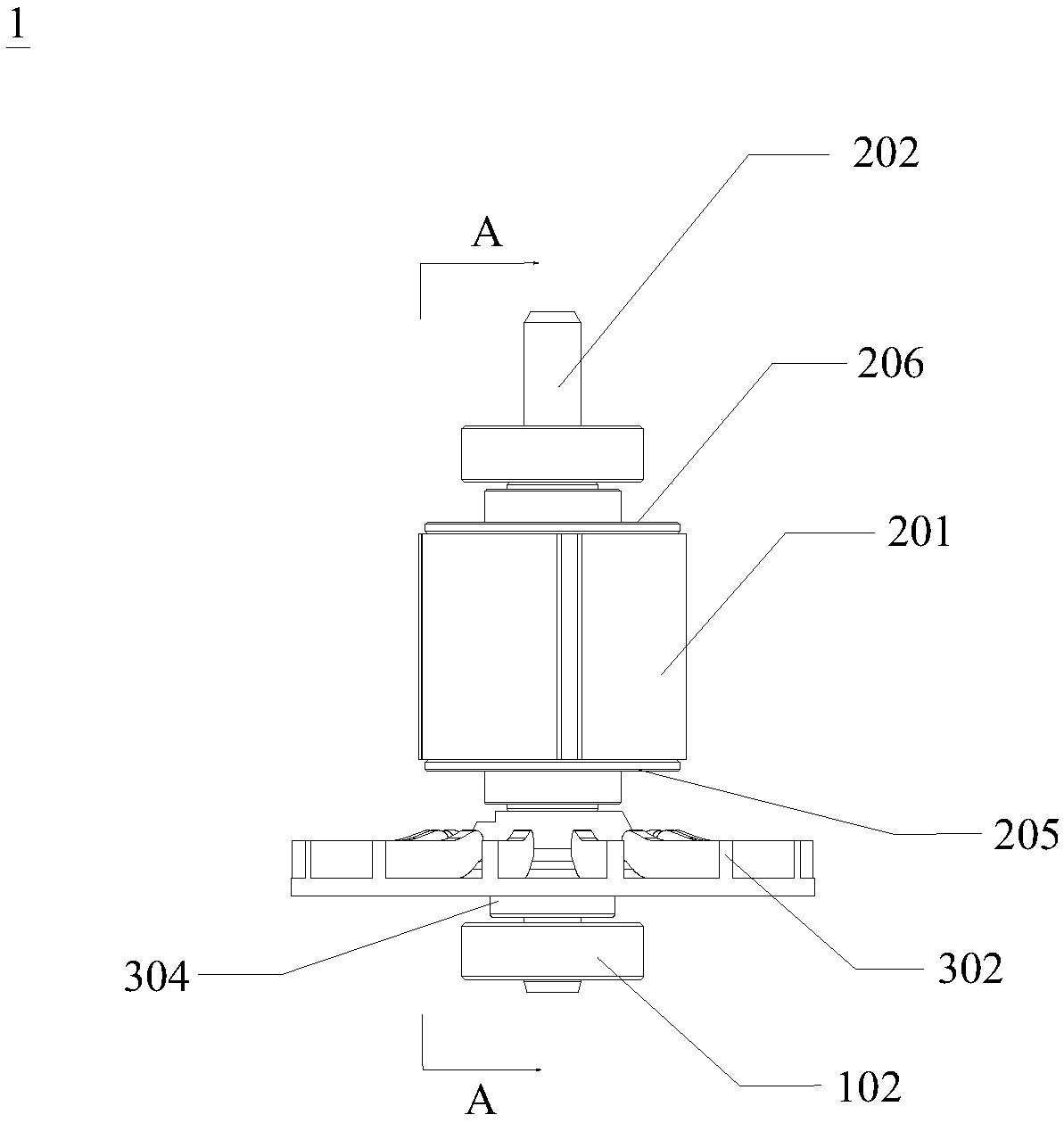

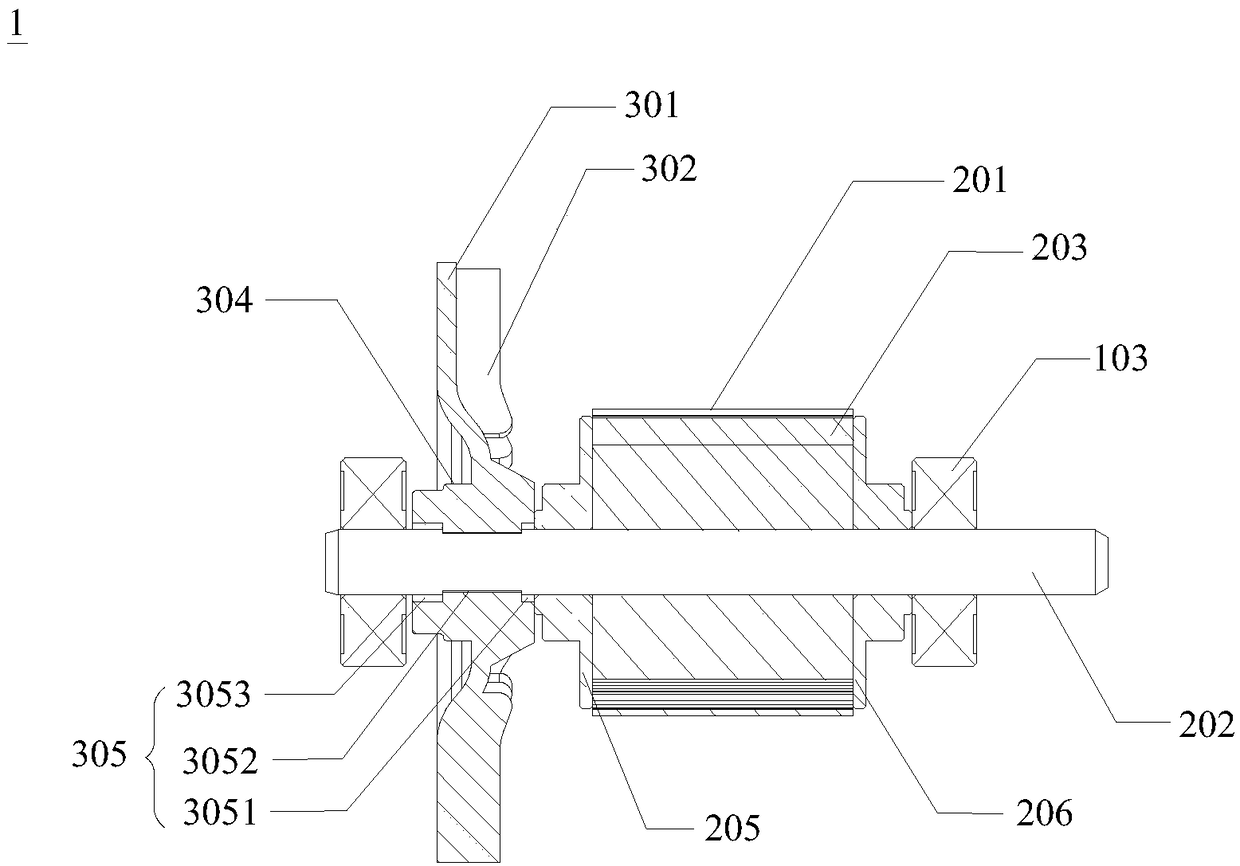

[0025] see Figure 1 to Figure 8 , Figure 1 to Figure 8 A specific embodiment of the brushless motor 1 of the present invention is shown. To show the rotor assembly more clearly, Figure 1 to Figure 3 The middle stator assembly is not shown. In the embodiment shown in the drawings, the brushless motor 1 includes a stator assembly, a rotor assembly disposed in the stator assembly, and a shaft core 202 fixed on the rotor assembly. The fan blade 30; wherein, the shaft core 202 is formed with a straight knurled portion 2021, and the through hole 305 of the fan blade 30 is in interference fit with the straight knurled portion 2021 so that the fan blade 30 It is fixed on the shaft core 202. Preferably, in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com