A kind of preparation method of counter electrode material of dye-sensitized solar cell

A solar cell and electrode material technology, applied in photosensitive equipment, electrolytic capacitors, circuits, etc., can solve the problems of low electrocatalytic efficiency, easy agglomeration, and low photoelectric conversion efficiency of electrode materials, so as to facilitate photoelectric conversion and energy storage, and not easy to agglomerate , the effect of improving the electrocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

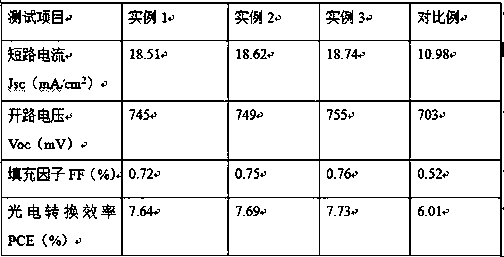

example 1

[0024] Take 12g of p-nitroaniline in a beaker, add 35mL of hydrochloric acid with a mass fraction of 20%, heat up to 70°C, heat and stir until the solids are completely dissolved, then place the beaker in an ice bath and cool it rapidly to 0°C. Stir at a speed of 300r / min and add 40mL of sodium nitrite aqueous solution with a mass fraction of 5%, react for 30min, then add 4g of sulfamic acid to the beaker, filter with suction, and separate to obtain the filtrate, which is p-nitroaniline diazo Salt solution: take 10 g of multi-walled carbon nanotubes and place them in a three-necked flask, add 200 mL of deionized water, place the three-necked flask in an ultrasonic disperser, and ultrasonically disperse at a frequency of 25 kHz for 30 min at a temperature of 50 ° C. Add 40mL of p-nitroaniline diazonium salt solution and 4g of tungsten carbide dropwise to the three-necked flask at a rate of 3mL / min through the funnel, react while adding dropwise, until the dropwise addition is co...

example 2

[0026] Take 13g of p-nitroaniline in a beaker, add 37mL of hydrochloric acid with a mass fraction of 20%, heat up to 75°C, keep stirring until the solids are completely dissolved, then place the beaker in an ice bath and cool it down to 3°C rapidly. Stir at a speed of 350r / min and add 45mL of sodium nitrite aqueous solution with a mass fraction of 5%, react for 33min, then add 4g of sulfamic acid to the beaker, filter with suction, and separate to obtain the filtrate, which is p-nitroaniline diazo Salt solution: Take 11g of multi-walled carbon nanotubes and place them in a three-necked flask, add 250mL of deionized water, place the three-necked flask in an ultrasonic disperser, and ultrasonically disperse at a frequency of 27kHz for 33min at a temperature of 53°C. Add 45mL of p-nitroaniline diazonium salt solution and 4g of tungsten carbide dropwise to the three-necked flask at a rate of 3mL / min through the funnel, react while adding dropwise, until the dropwise addition is com...

example 3

[0028] Take 15g of p-nitroaniline in a beaker, add 40mL of hydrochloric acid with a mass fraction of 20%, heat up to 80°C, keep stirring until the solids are completely dissolved, then place the beaker in an ice bath and cool it down to 5°C rapidly. Stir at a speed of 400r / min and add 50mL of sodium nitrite aqueous solution with a mass fraction of 5%, react for 35min, then add 5g of sulfamic acid to the beaker, filter with suction, and separate to obtain the filtrate, which is p-nitroaniline diazo Salt solution; put 12g of multi-walled carbon nanotubes into a three-necked flask, add 300mL of deionized water, place the three-necked flask in an ultrasonic disperser, and ultrasonically disperse at a temperature of 55°C at a frequency of 30kHz for 35min. Add 50mL p-nitroaniline diazonium salt solution and 5g tungsten carbide dropwise to the three-necked flask at a rate of 4mL / min through the funnel, react while adding dropwise, until the dropwise addition is complete, suction filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com