Crystalline silicon solar cell main grid electrode paste for spraying and preparation method thereof

A technology for solar cells and busbar electrodes, applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of reducing slurry, affecting conductive performance, and not suitable for spraying processes, etc. Achieve the effects of saving dosage, simple preparation method and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

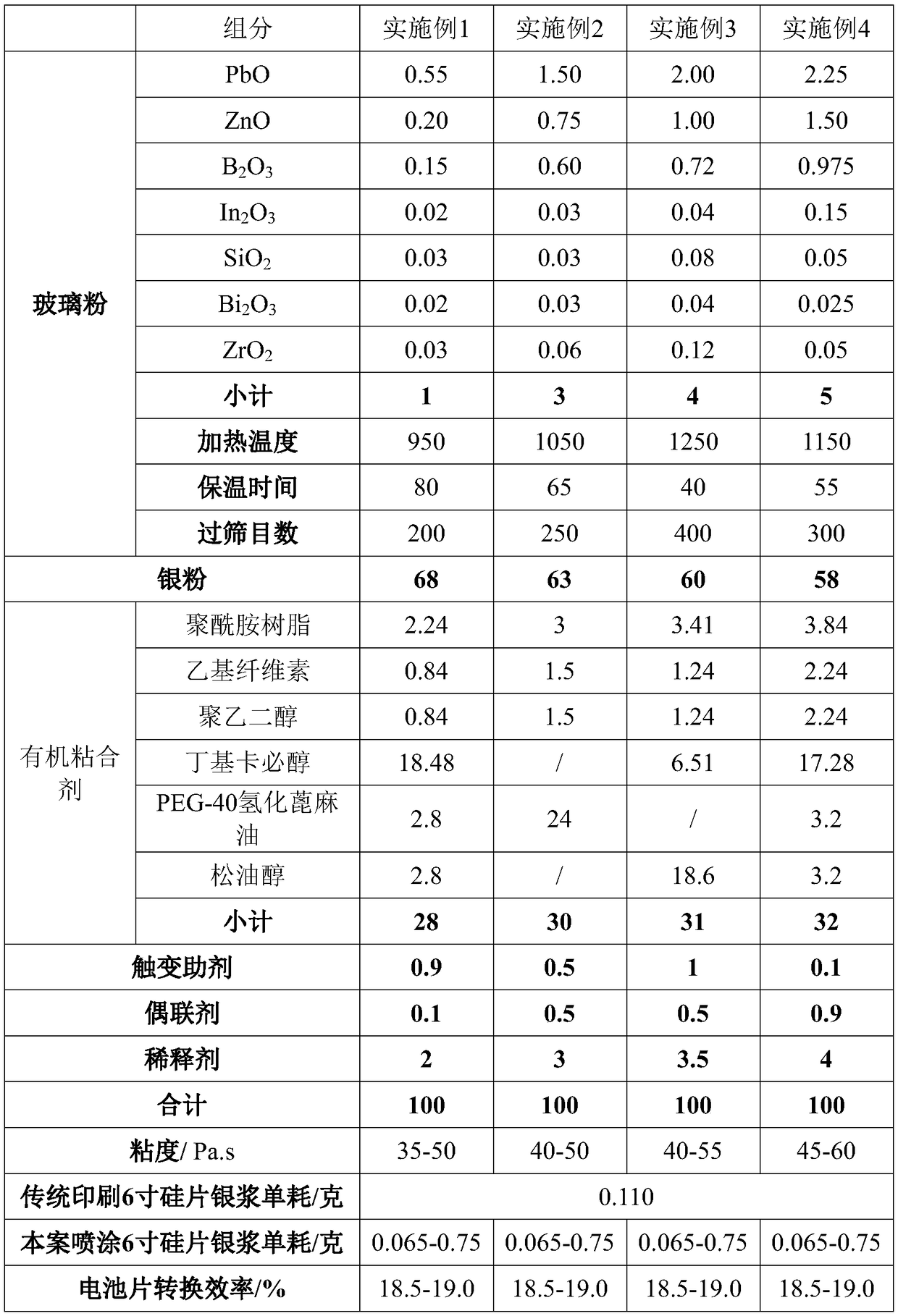

Embodiment 1

[0022] This embodiment provides a crystalline silicon solar cell main grid electrode paste for spraying, which consists of 68 parts of silver powder, 1 part of glass binder, 28 parts of organic binder, Prepared by mixing 0.9 parts of thixotropic additives, 0.1 parts of coupling agent and 2 parts of diluent; wherein, the glass binder consists of 0.55 parts of PbO, 0.20 parts of ZnO, 0.15 parts of B 2 o 3 , 0.02 copies of In 2 o 3 , 0.03 parts of SiO 2 , 0.02 parts of Bi 2 o 3 , 0.03 parts of ZrO 2 Prepared by mixing; the organic binder consists of 2.24 parts of polyamide resin, 0.84 parts of ethyl cellulose, 0.84 parts of polyethylene glycol, 18.48 parts of butyl carbitol, 2.8 parts of PEG-40 Prepared by mixing hydrogenated castor oil and 2.8 parts of terpineol.

Embodiment 2

[0024] This embodiment provides a crystalline silicon solar cell main grid electrode paste for spraying, which consists of 63 parts of silver powder, 3 parts of glass binder, 30 parts of organic binder, Prepared by mixing 0.5 parts of thixotropic additive, 0.5 parts of coupling agent and 3 parts of diluent; wherein, the glass binder is composed of 1.50 parts of PbO, 0.75 parts of ZnO, 0.60 parts of B 2 o 3 , 0.03 copies of In 2 o 3 , 0.03 parts of SiO 2 , 0.03 parts of Bi 2 o 3 , 0.06 parts of ZrO 2 Prepared by mixing; the organic binder is prepared by mixing 3 parts of polyamide resin, 1.5 parts of ethyl cellulose, 1.5 parts of polyethylene glycol, and 24 parts of PEG-40 hydrogenated castor oil.

Embodiment 3

[0026] This embodiment provides a crystalline silicon solar cell main grid electrode paste for spraying, which consists of 60 parts of silver powder, 4 parts of glass binder, 31 parts of organic binder, Prepared by mixing 1 part of thixotropic additive, 0.5 part of coupling agent and 3.5 parts of diluent; wherein, the glass binder consists of 2.00 parts of PbO, 1.00 parts of ZnO, 0.72 parts of B 2 o 3 , 0.04 copies of In 2 o 3 , 0.08 parts of SiO 2 , 0.04 parts of Bi 2 o 3 , 0.12 parts of ZrO 2 Mix and prepare; Described organic binder is by the polyamide resin of 3.41 parts, the ethyl cellulose of 1.24 parts, the polyethylene glycol of 1.24 parts, the butyl carbitol of 6.51 parts, the terpineol of 18.6 parts Prepared by mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com