Manufacturing method of solar cell with four layers of anti-reflection films

A technology of solar cells and manufacturing methods, applied in the field of solar cells, which can solve the problems of cumbersome manufacturing, lack of manufacturing methods for solar cell panels, and inability to mass-produce, etc., and achieve the effects of uniform coating color, improved attenuation trend, and improved conversion rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

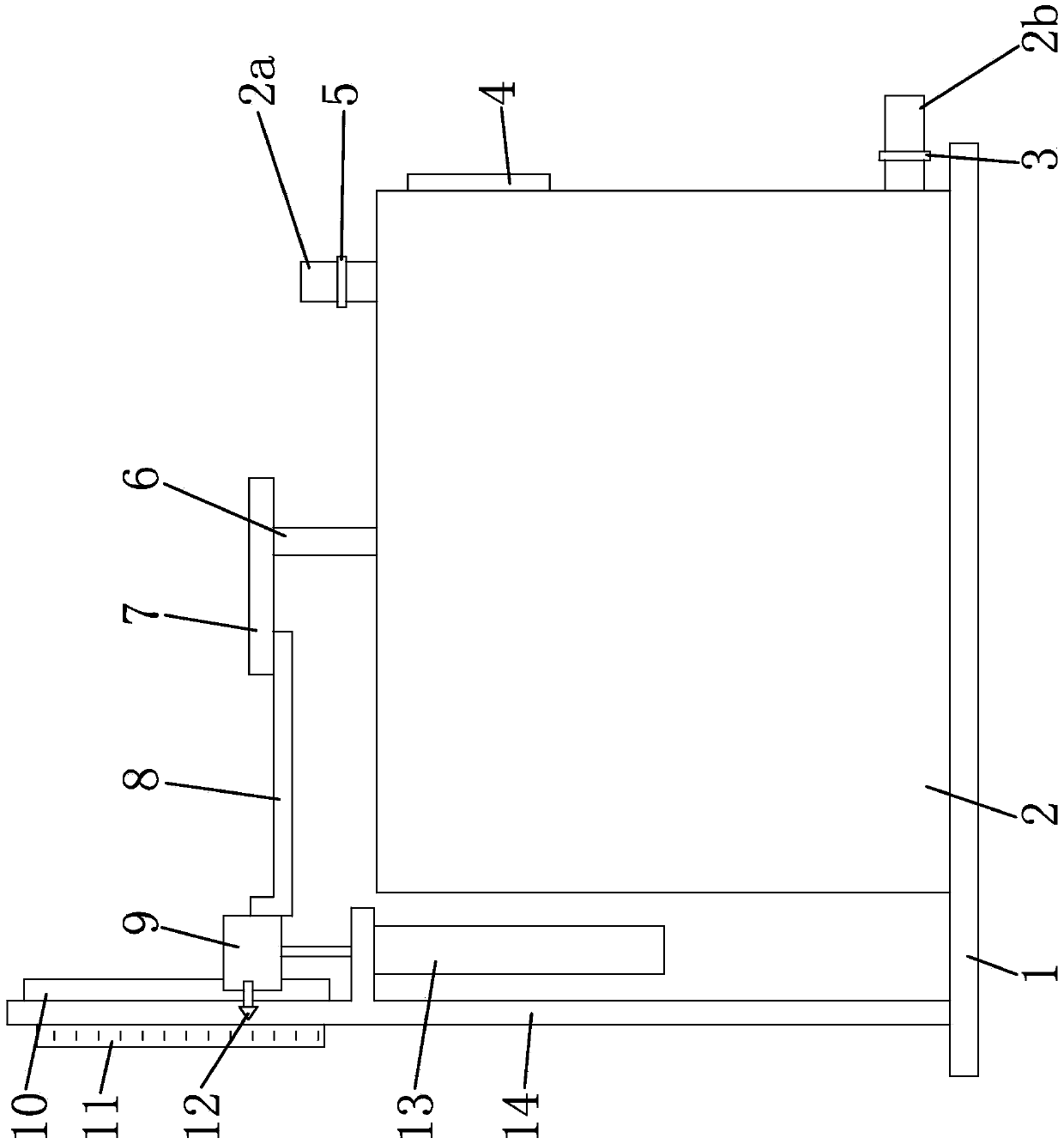

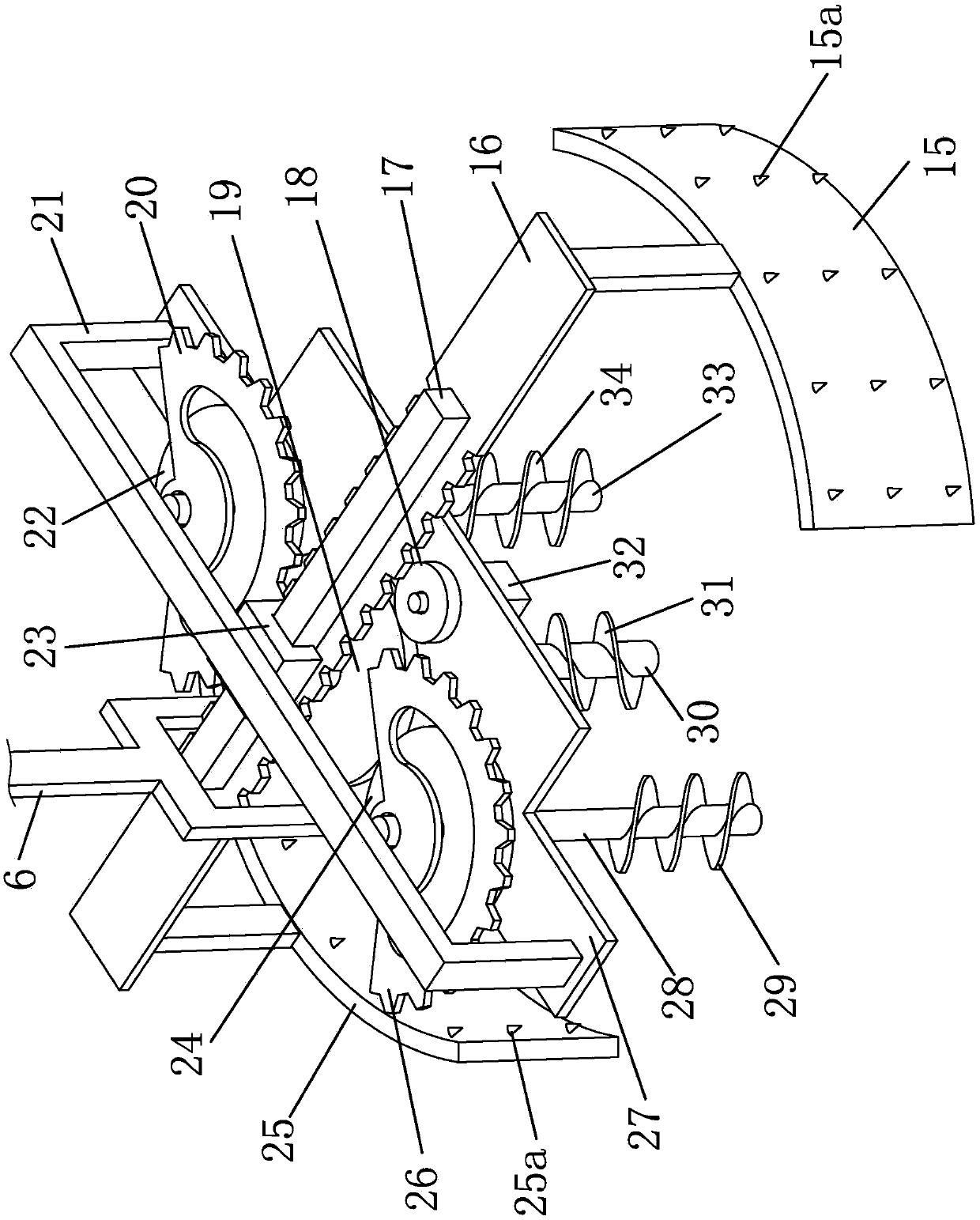

[0063] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0064] Such as figure 1 Shown, this has the manufacture method of the solar cell of four-layer anti-reflection film, comprises the steps:

[0065] a. Wafer inspection: inspect incoming silicon wafers and remove unqualified silicon wafers;

[0066] b. Surface texturing: put the tested silicon wafer into alkaline texturing solution for surface corrosion texturing;

[0067] c. Diffusion knotting: put the textured silicon wafer into a diffusion furnace for diffusion knotting;

[0068] d. Dephosphorous silicon glass: put the diffused and bonded silicon wafer into an acidic solution for dephosphorous silicon glass treatment;

[0069] e. Etching: Put the silicon wafer of dephosphorous silicon glass on the etching machine for w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com