Heat exchanging system using water circulation to intensify medium- and low-temperature paraffin phase change heat storage

A phase change heat storage and water circulation technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems affecting the large-scale application of materials, the inoperability of agitators, and the complex preparation process, and reduce Design complexity, improve heat storage and heat transfer efficiency, and improve the effect of convective heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

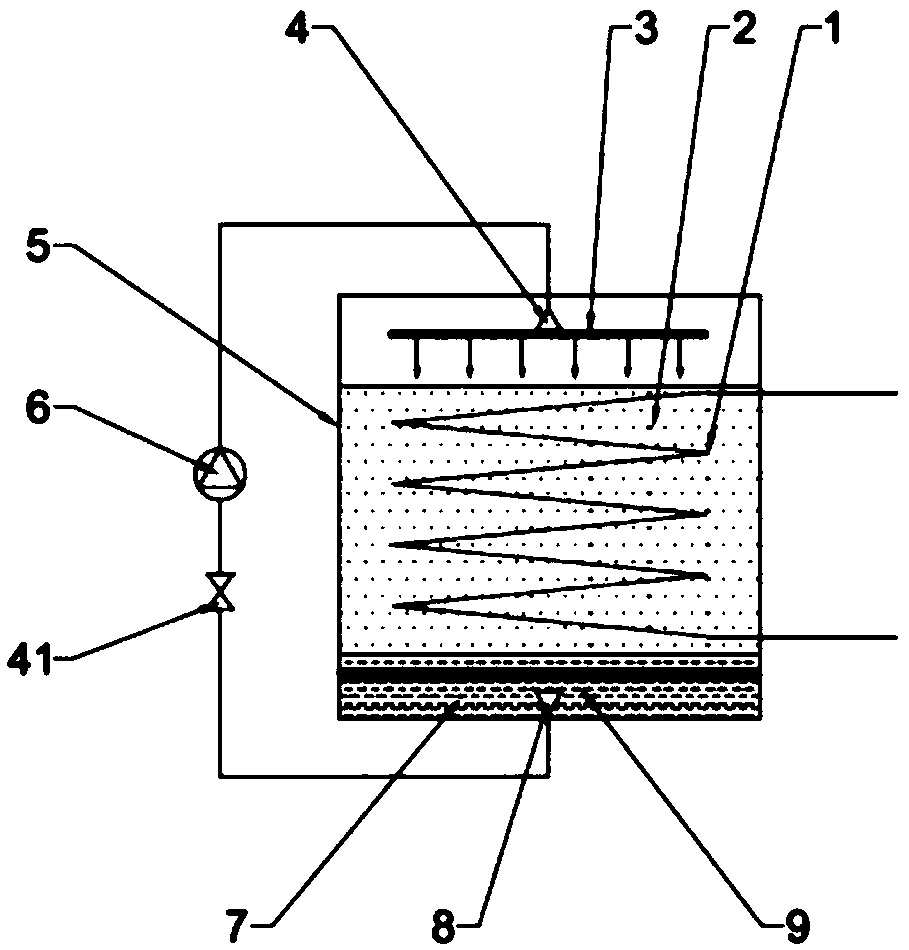

[0031] An embodiment of the heat exchange system using water circulation to strengthen the heat storage of medium and low temperature paraffin phase change heat storage in the present invention, the structural diagram of the system of using water circulation to strengthen the heat exchange of medium and low temperature paraffin phase change heat storage described in this embodiment is as follows figure 1 Shown:

[0032]It includes a heat storage container 5 and a water circulation system that circulates water in the heat storage container 5. The upper part of the heat storage container 5 is equipped with a paraffin phase change material 2, the lower part of the heat storage container 5 is equipped with water 7, and the middle of the heat storage container 5 is equipped with a heat exchanger. Heater 1; water circulation system and heat exchanger 1 operate simultaneously, and heat exchanger 1 is a kind of in coil heat exchanger, finned tube heat exchanger; Described water circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com