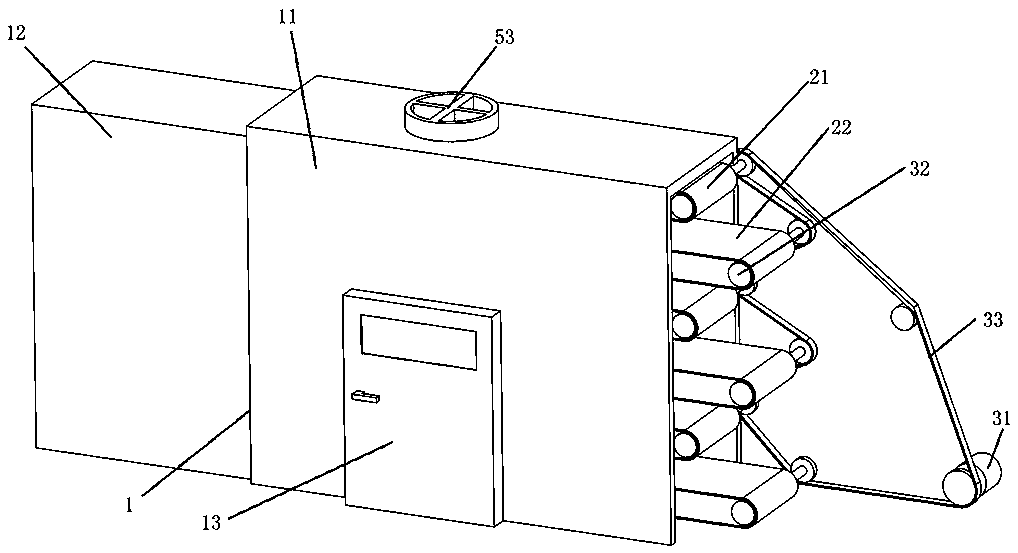

Sheet jelly drying device

A drying device and powder skin technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of short drying distance and poor thermal insulation effect, and achieve good drying effect, improve drying effect, and uniformity. The effect of air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

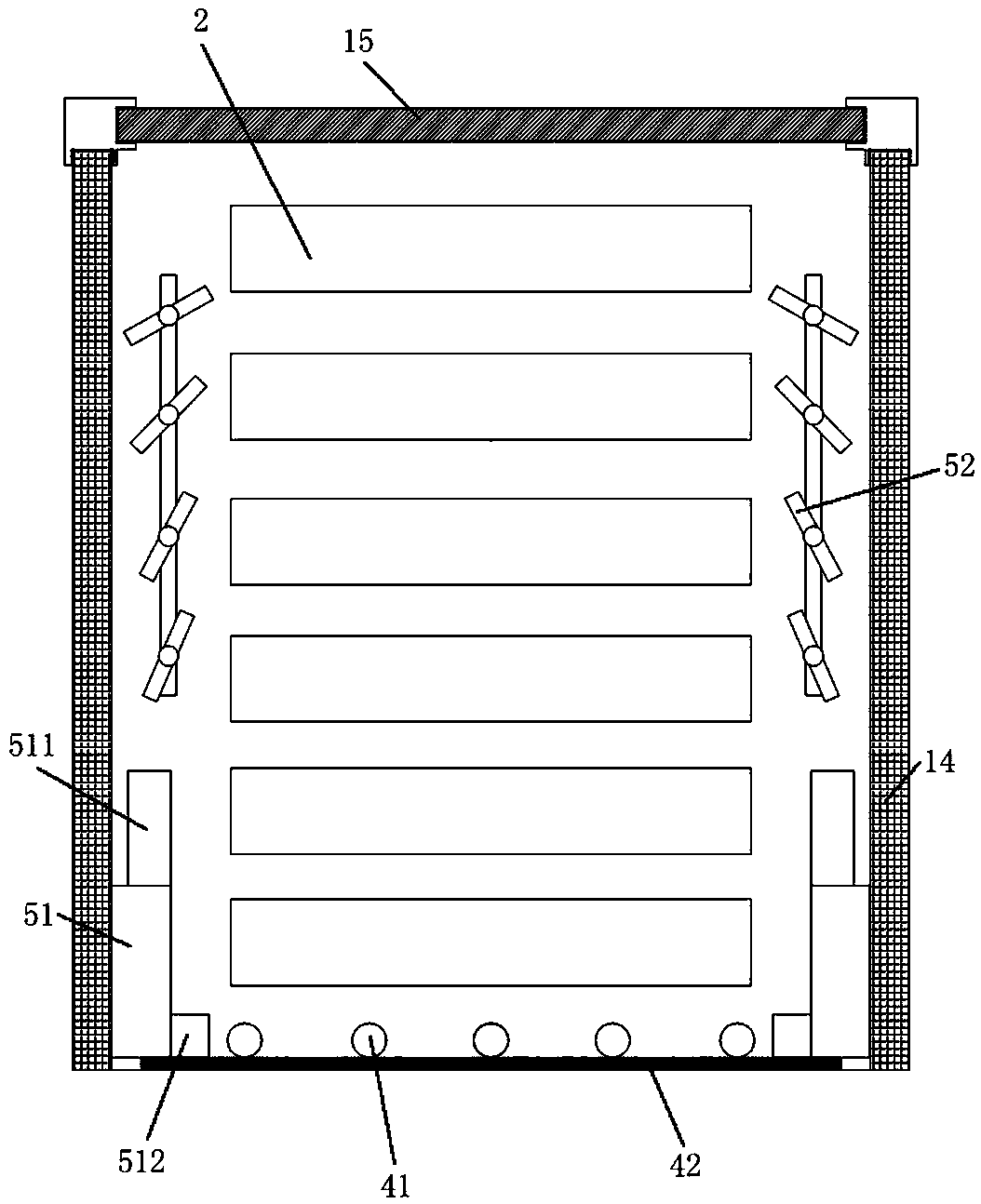

Method used

Image

Examples

Embodiment 2

[0041] The technical scheme described in embodiment two is similar to embodiment, and its difference is:

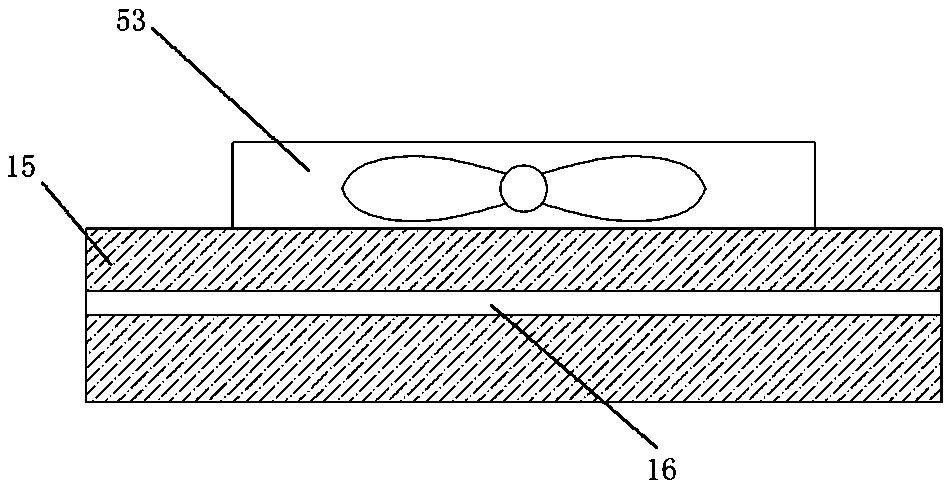

[0042] Such as image 3 As shown, in this embodiment, the drying box housing 1 includes a side plate 14 and a top plate 15, the side plate 14 is a thermal insulation side plate 14, and the top plate 15 is a microporous sponge rubber plate. The heating resistance wire 16 is embedded in the top plate 15 , and the air supply device also includes a second fan 53 arranged on the top plate 15 . The implementation of this embodiment makes the heating resistance wire 16 make the top plate 15 have a certain temperature by heating the top plate 15, so as to prevent water vapor from condensing and dripping on the top plate 15 during the drying operation, which will affect the drying effect; at the same time, the second fan 53 The top plate 15 is provided with an outward draft effect by means of an outward fan, and the draft effect makes the micropores of the top plate 15 have a neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com