Construction method of hanging basket cantilever pouring for multi-chamber corrugated steel web continuous girder bridge

The technology of corrugated steel web and steel web is applied in the field of hanging basket cantilever pouring construction method, which can solve the problems of increasing the time for bundling the steel bars of the box girder, unfavorable control of the overall construction period, and increasing the construction period of the segment, etc. High efficiency, convenient construction, fast cycle and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

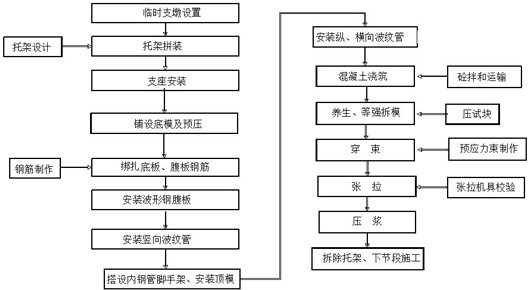

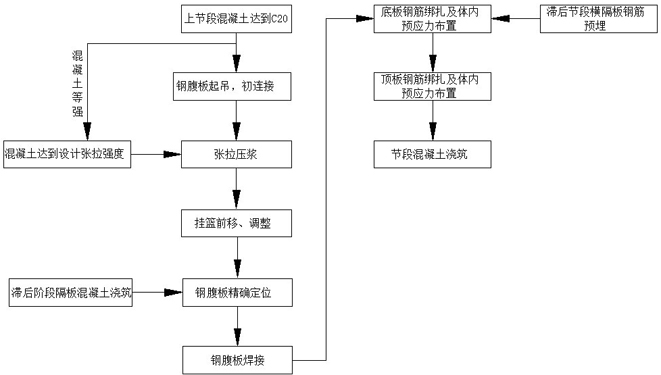

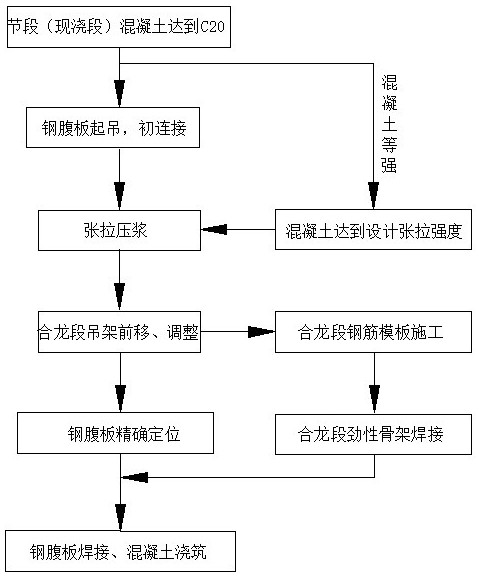

[0038] Combine below Figure 1-4 The present invention is further described, but the protection scope of the present invention is not limited to the content.

[0039] For the sake of clarity, not all features of an actual embodiment are described. In the following description, well-known functions and constructions are not described in detail since they would obscure the invention with unnecessary detail and should be considered in the development of any actual embodiment. , a great deal of implementation detail must be worked out to achieve the developer's specific goals, such as changing from one embodiment to another in accordance with system-related or business-related constraints, and it should also be recognized that such development work may be complex and time-consuming Yes, but just routine work for those skilled in the art.

[0040]A hanging basket cantilever pouring construction method for a multi-chamber corrugated steel web continuous girder bridge, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com