Preparation method of Tb-Dy-Fe-Co alloy magnetic nano pipe array

A tb-dy-fe-co, 1.tb-dy-fe-co technology, applied in the field of uniform polycrystalline materials, can solve the problem of improving the performance of nanowire arrays, not applicable to magneto-optical storage materials, nanowires The problem of uneven composition, etc., achieves the effect of uniform hole size, high temperature resistance and good insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

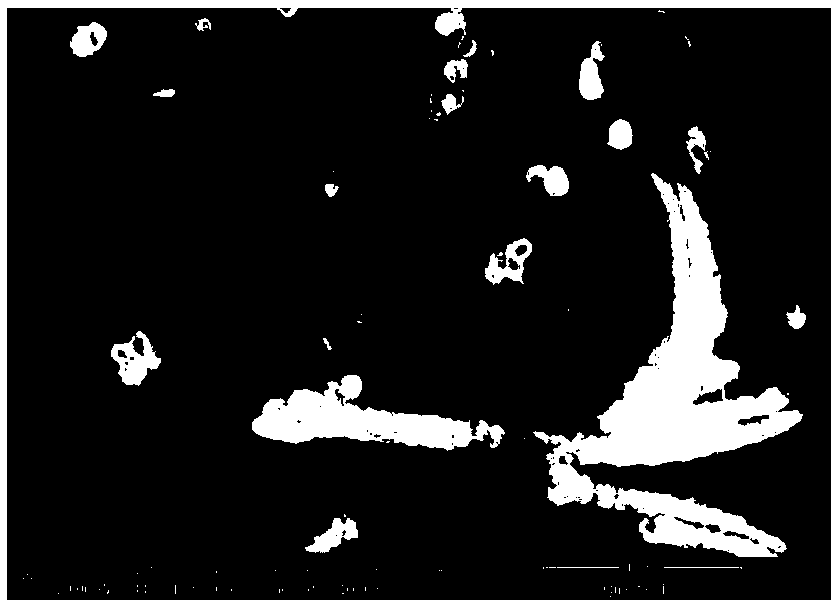

Image

Examples

Embodiment 1

[0063] In the first step, the AAO template is sprayed with gold:

[0064] Put the AAO template into the ion sputtering apparatus and put it into the ion sputtering apparatus, with Au as the target material, at a sputtering current of 15mA and a vacuum of 3x10 -2Spray gold for 5 minutes under the condition of Pa, sputter a layer of Au atoms on the back of the AAO template, and the thickness of the Au atomic layer is 1um, thus completing the gold spraying treatment of the AAO template;

[0065] The second step, the preparation of Tb-Dy-Fe-Co alloy electrodeposition solution:

[0066] the required amount of Fe 2 The Tb alloy is dissolved in reagent pure hydrochloric acid with a percentage concentration of 38%, and the required amount of DyF 3 , FeCl 2 4H 2 O, CoCl 2 ·6H 2 O, H 3 BO 3 , citric acid C 6 h 8 o 7 and ascorbic acid C 6 h 8 o 6 Add it into deionized water, and then mix together to prepare the Tb-Dy-Fe-Co alloy electrodeposition solution. The concentration...

Embodiment 2

[0078] In the first step, the AAO template is sprayed with gold:

[0079] Put the AAO template into the ion sputtering apparatus, with Au as the target material, at a sputtering current of 15mA and a vacuum of 3x10 -2 Spray gold for 8 minutes under the condition of Pa, sputter a layer of Au atoms on the back of the AAO template, and the thickness of the Au atomic layer is 5um, thus completing the gold spraying treatment of the AAO template;

[0080] The second step, the preparation of Tb-Dy-Fe-Co alloy electrodeposition solution:

[0081] the required amount of Fe 2 The Tb alloy is dissolved in reagent pure hydrochloric acid with a percentage concentration of 38%, and the required amount of DyF 3 , FeCl 2 4H 2 O, CoCl 2 ·6H 2 O, H 3 BO 3 , citric acid C 6 h 8 o 7 and ascorbic acid C 6 h 8 o 6 Add it into deionized water, and then mix together to prepare the Tb-Dy-Fe-Co alloy electrodeposition solution. The concentration of each material in the electrodeposition s...

Embodiment 3

[0093] In the first step, the AAO template is sprayed with gold:

[0094] Put the AAO template into the ion sputtering apparatus, with Au as the target material, at a sputtering current of 15mA and a vacuum of 3x10 -2 Spray gold for 10 minutes under the condition of Pa, sputter a layer of Au atoms on the back of the AAO template, and the thickness of the Au atomic layer is 10um, thus completing the gold spraying treatment of the AAO template;

[0095] The second step, the preparation of Tb-Dy-Fe-Co alloy electrodeposition solution:

[0096] the required amount of Fe 2The Tb alloy is dissolved in reagent pure hydrochloric acid with a percentage concentration of 38%, and the required amount of DyF 3 , FeCl 2 4H 2 O, CoCl 2 ·6H 2 O, H 3 BO 3 , citric acid C 6 h 8 o 7 and ascorbic acid C 6 h 8 o 6 Add it into deionized water, and then mix together to prepare the Tb-Dy-Fe-Co alloy electrodeposition solution. The concentration of each material in the electrodeposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com