A production method of φ36~40mm HRB500E threaded steel bar

A technology of threaded steel bar and production method, applied in the field of iron and steel metallurgy, can solve the problems of large difference in microstructure of steel bar, small rolling compression ratio, low performance qualification rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Steelmaking

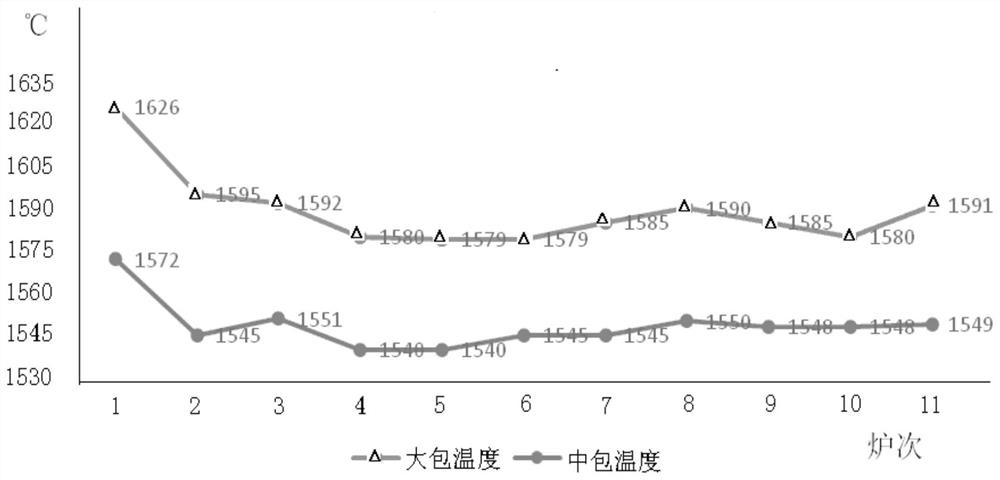

[0062] Taking 100t converter smelting 11 furnaces of Φ36~40mm HRB500E rebar as an example, the following steps of smelting test were carried out:

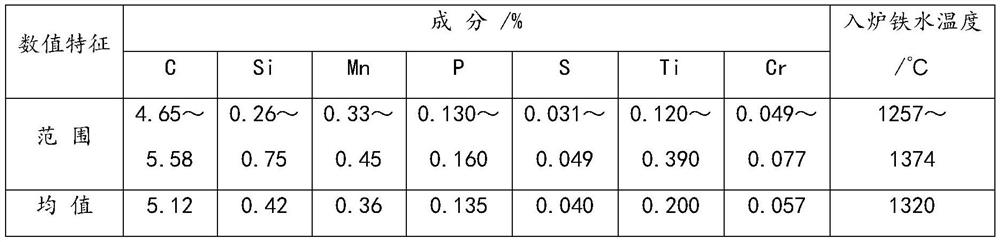

[0063] 1) Raw material requirements

[0064] The composition and temperature of molten iron are shown in Table 1 below.

[0065] Table 1 Composition and temperature of molten iron used in 11 heats of HRB500E steel

[0066]

[0067] (2) Lime composition (%): CaO>90, SiO 2 ≤1.5, S310ml.

[0068] 2) Loading system:

[0069] The loading amount of each raw material in the converter and the amount of slag in the smelting process are shown in Table 2 below.

[0070] Table 2 The amount of metal material charged in 11 heats of HRB500E steel and the amount of slag added in the smelting process

[0071]

[0072] Among them, the composition of the slagging agent is MnO≥13%, Fe 2 o 3 ≥20%, SiO 2 ≤20%, P≤0.20%, S≤0.20%, moisture≤3%.

[0073] 3) Smelting conditions

[0074] (1) The working oxygen pressure ...

experiment example 1

[0126] The multiple batches of φ36~40mm HRB500E threaded steel bars prepared in Example 1 are detected, specifically as follows:

[0127] 1 produces the effect

[0128] The microstructure and mechanical properties of the prepared batches of Φ36-40mm HRB500E threaded steel bars meet the GB / T1499.2-2018 standard and user requirements, and the performance qualification rate reaches 100%.

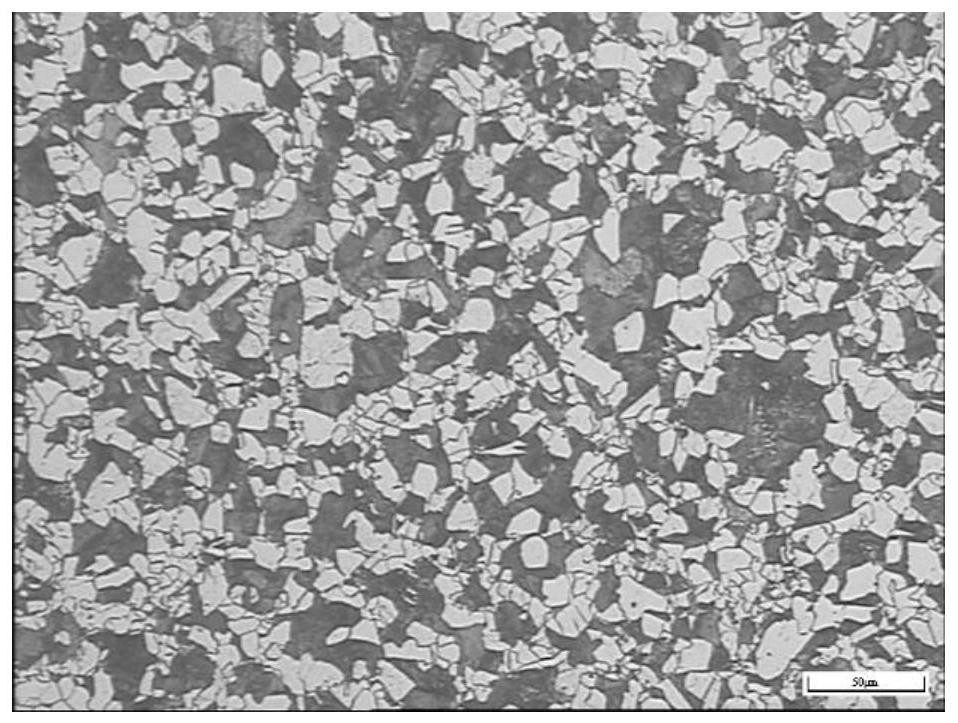

[0129] 2 microstructure

[0130] The microscopic inclusion ratings of Φ40mm HRB500E steel bars are shown in Table 9 below.

[0131] Table 9 Inclusion rating / level of Φ40mm HRB500E steel bars

[0132]

[0133] It can be seen from Table 9 that there are a small amount of silicate and spherical oxide inclusions in the steel bar, but no other inclusions, indicating that the steel is relatively clean.

[0134] At the same time, the metallographic microstructure of Φ40mm HRB500E steel bar is ferrite + pearlite, pearlite accounts for about 53%, and the grain size is 9.5-10. Its microstructure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com