3D-printing composite material with fragrance and antibacterial property, preparation method and application thereof

A technology of 3D printing and composite materials, applied in the field of new materials and new processing of polymer materials, can solve the problems of poor compatibility of fragrance-type composite materials, limited categories and product forms, and few reports on preparation methods, and achieve fragrance retention time. Long-lasting, process formulation optimization, and compatibility problem-solving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]

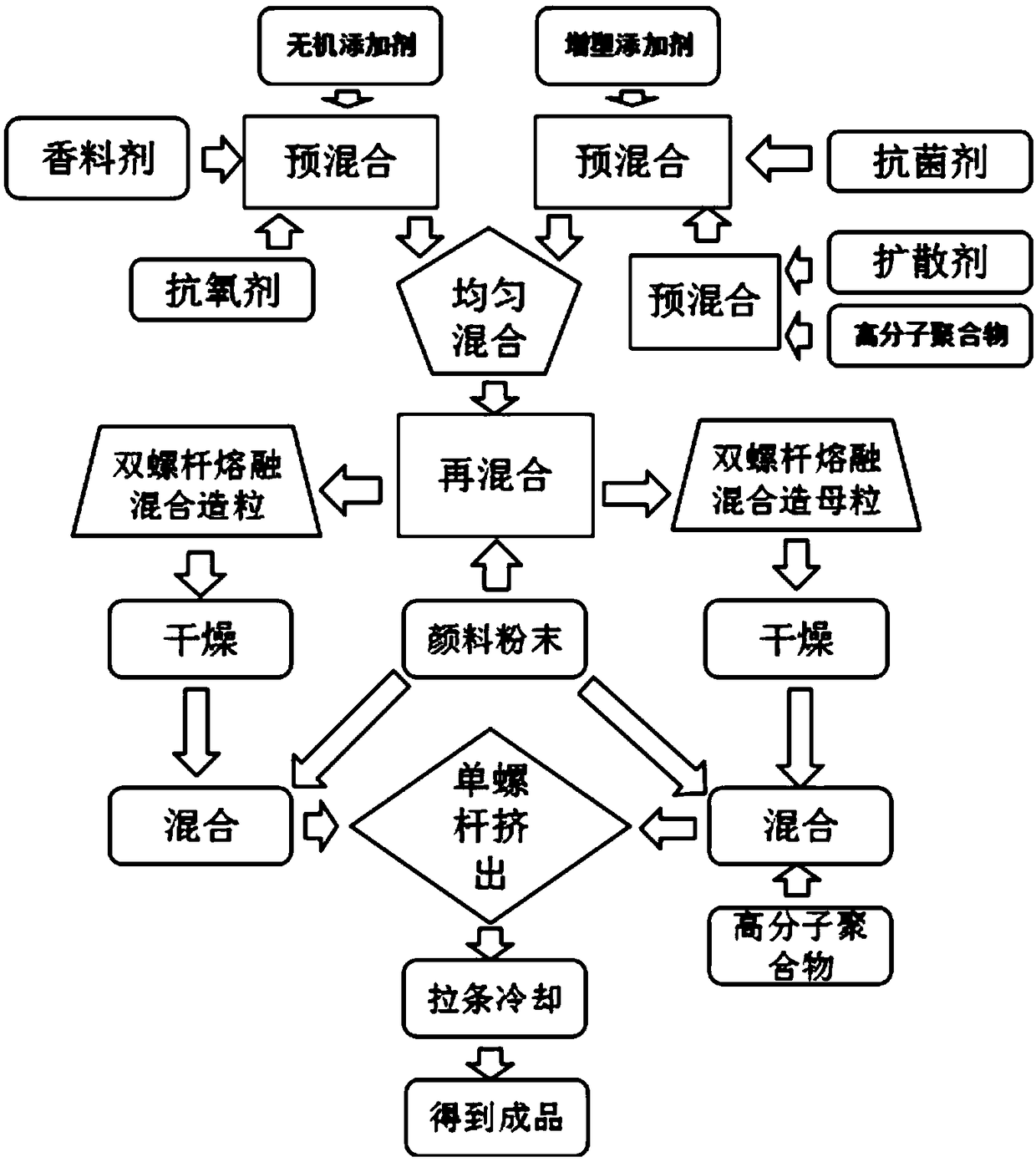

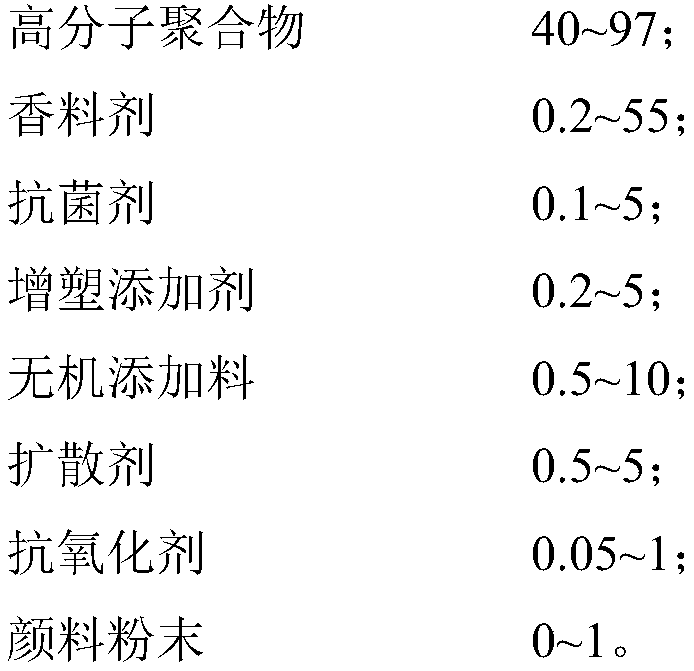

[0048] refer to figure 1 The technological process, first 0.1 weight part of antioxidant 1010, 0.05 weight part of antioxidant 168, 0.2 weight part of rose fragrance type solid fragrance, 0.5 weight part of hydrophobic silicon dioxide and 1.0 weight part of titanium dioxide are added to the high-speed The mixer is pre-mixed and mixed evenly to obtain a flavor pre-mix; wherein the pre-mix speed of the high-speed mixer is 300r / min, the pre-mix time is 1min, and the pre-mix temperature is 30°C; then 95.95 parts by weight of polyethylene glycol Lactone and 1.0 parts by weight of methyl silicone oil are added to a high-speed mixer with a premixing speed set at 500r / min, a premixing time set at 1min, and a premixing temperature of 40°C for premixing to obtain a high-molecular polymer diffusing agent Mixture; then 0.2 parts by weight of nano-zinc oxide microparticles, 0.2 parts by weight of stearic acid amide and 0.8 parts by weight of rosin are added to the high-speed mi...

Embodiment 2

[0050]

[0051] First, 0.1 parts by weight of antioxidant 1010, 0.05 parts by weight of antioxidant 168, 1.0 parts by weight of rose fragrance type solid fragrance, 0.5 parts by weight of hydrophobic silicon dioxide and 1.0 parts by weight of titanium dioxide are added to a high-speed mixer for pre-treatment. Mix and mix evenly, and obtain the fragrance premix; wherein the premix speed of the high-speed mixer is 300r / min, the premix time is 1min, and the premix temperature is 30°C; then 95.15 parts by weight of polycaprolactone, 1.0 Add the methyl silicone oil in parts by weight to a high-speed mixer whose premixing speed is set to 500r / min, the premixing time is set to 1min, and the premixing temperature is 40°C to premix evenly to obtain a polymer diffusing agent mixture; 0.2 parts by weight of nano-zinc oxide microparticles, 0.2 parts by weight of stearic acid amide and 0.8 parts by weight of rosin are added to the high-speed mixer and pre-mixed again with the polymer dif...

Embodiment 3

[0053]

[0054] First, 0.1 parts by weight of antioxidant 1010, 0.05 parts by weight of antioxidant 168, 2.0 parts by weight of rose fragrance type solid fragrance, 0.5 parts by weight of hydrophobic silicon dioxide and 1.0 parts by weight of titanium dioxide are added to a high-speed mixer for pre-treatment. Mix and mix evenly, and obtain the fragrance premix; wherein the premix speed of the high-speed mixer is 300r / min, the premix time is 1min, and the premix temperature is 30°C; then 94.15 parts by weight of polycaprolactone, 1.0 Add the methyl silicone oil in parts by weight to a high-speed mixer whose premixing speed is set to 500r / min, the premixing time is set to 1min, and the premixing temperature is 40°C to premix evenly to obtain a polymer diffusing agent mixture; 0.2 parts by weight of nano-zinc oxide microparticles, 0.2 parts by weight of stearic acid amide and 0.8 parts by weight of rosin are added to the high-speed mixer and pre-mixed again with the polymer dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com