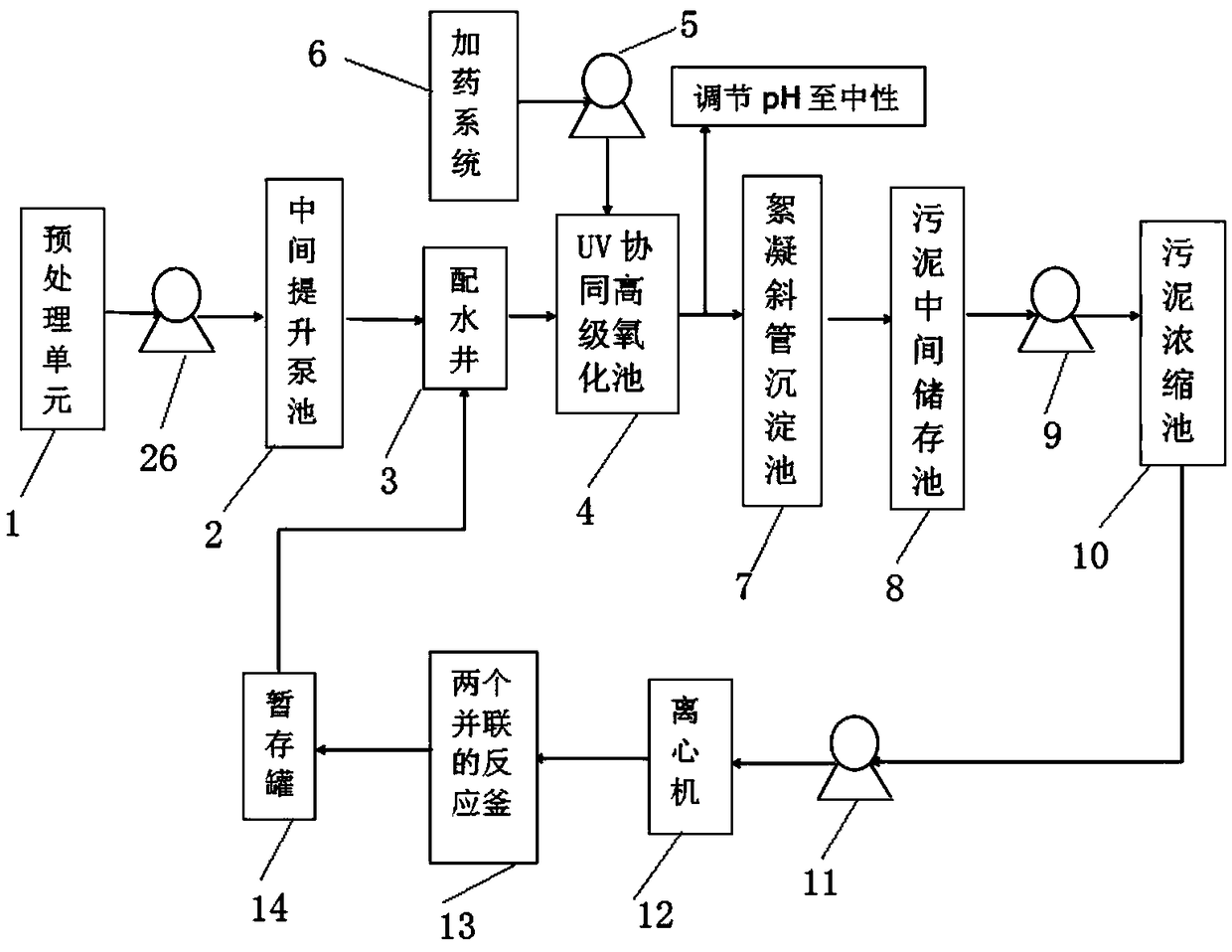

Continuous treatment system and treatment process for high-concentration chemical oxygen demand (COD) in industrial wastewater

A technology for industrial waste water and treatment system, applied in the field of continuous treatment system and treatment process of high concentration COD, can solve the problems of high COD content, not reaching the first-class A standard, not providing a COD treatment system, etc., and achieving convenient operation and management , Low investment and operation cost, avoid the effect of iron mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The sewage collected in this embodiment all comes from Yongning County Industrial Park, wherein industrial wastewater accounts for more than 60%, and the rest is domestic sewage.

[0084] The specific process is as follows:

[0085] The invention provides a continuous treatment process for high COD in industrial waste water, which comprises the steps of:

[0086] S1: the industrial waste water enters the middle lifting pump pool 2 through the middle lifting pump 26, and then enters the water distribution well 3;

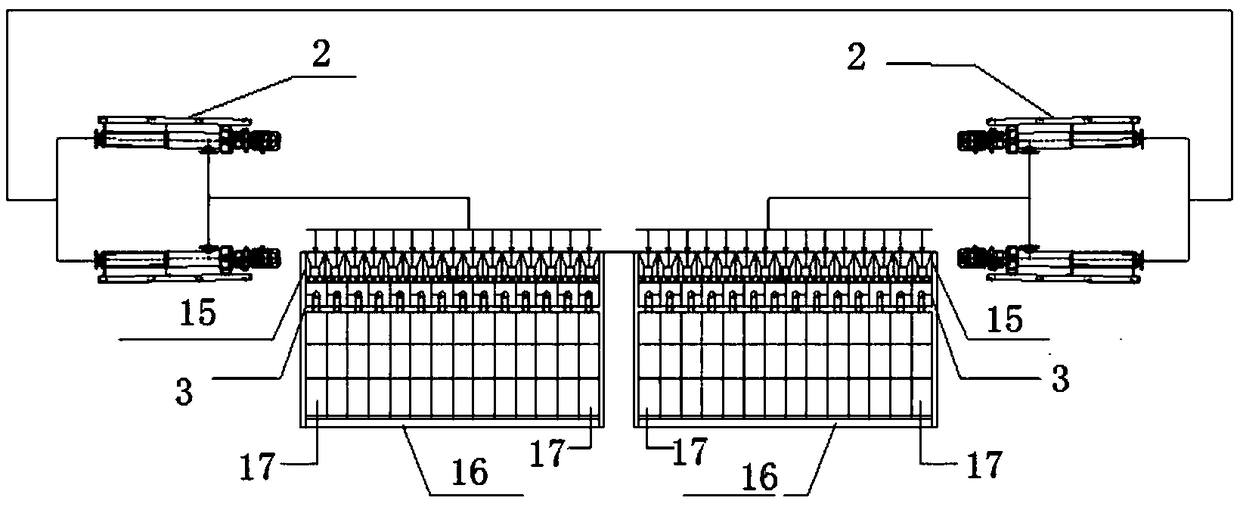

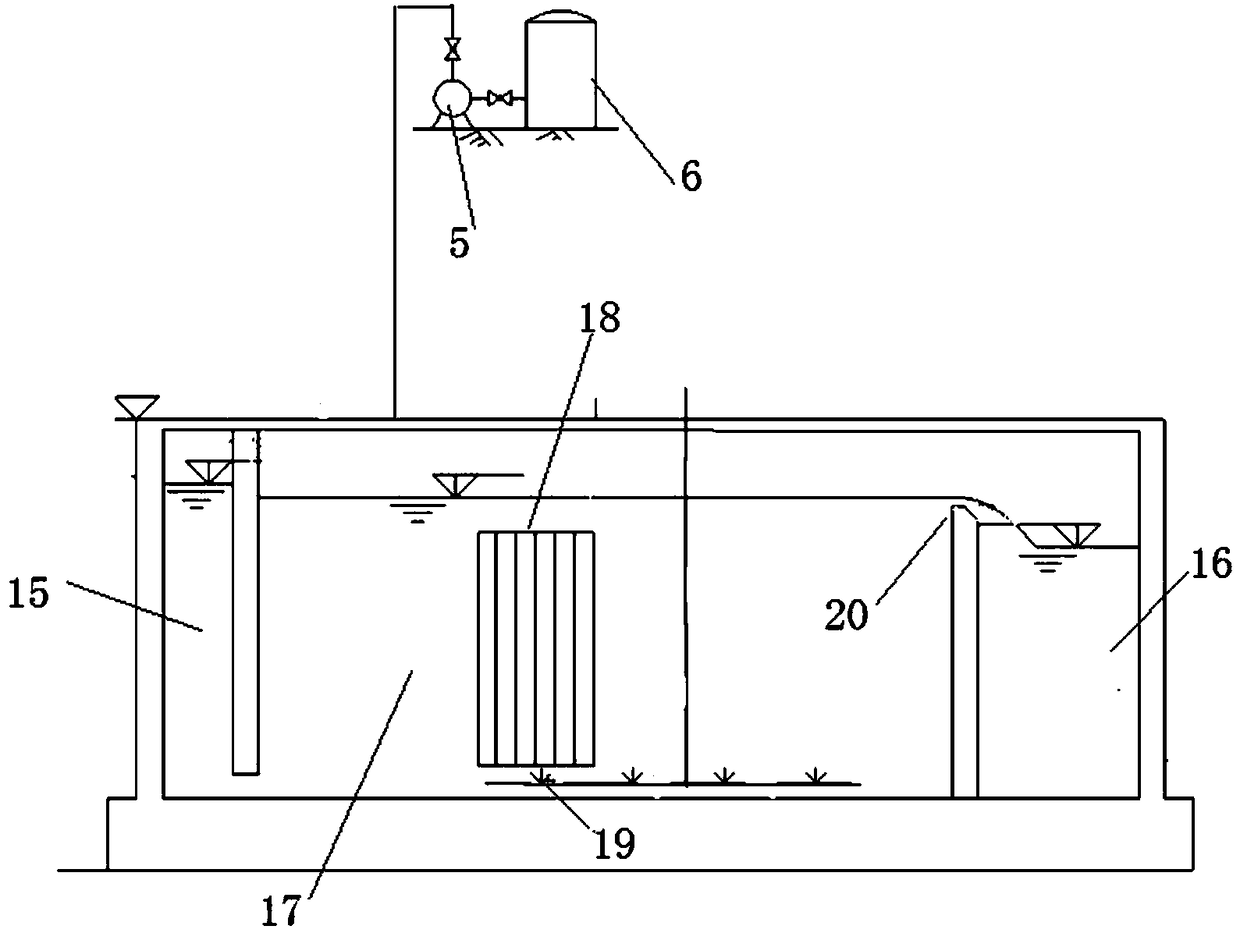

[0087] S2: Before entering the water distribution well 3, measure the COD content in the industrial wastewater by the water quality online detector, the COD content is 500mg / L, and calculate the amount of copper oxide and hydrogen peroxide that needs to be added. The measured industrial wastewater is transported from the water distribution well 3 to the front-end sump 15 of the UV synergistic advanced oxidation pool 4, and the dosing system 6 adds a certain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com