A method for extracting tungsten carbide and cobalt from waste cemented carbide

A technology of cemented carbide and tungsten carbide, which is applied in the direction of carbide, tungsten/molybdenum carbide, nickel halide, etc., can solve problems such as poor flow of electrolytic solution, solve pollution problems, increase contact area, reduce The effect of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

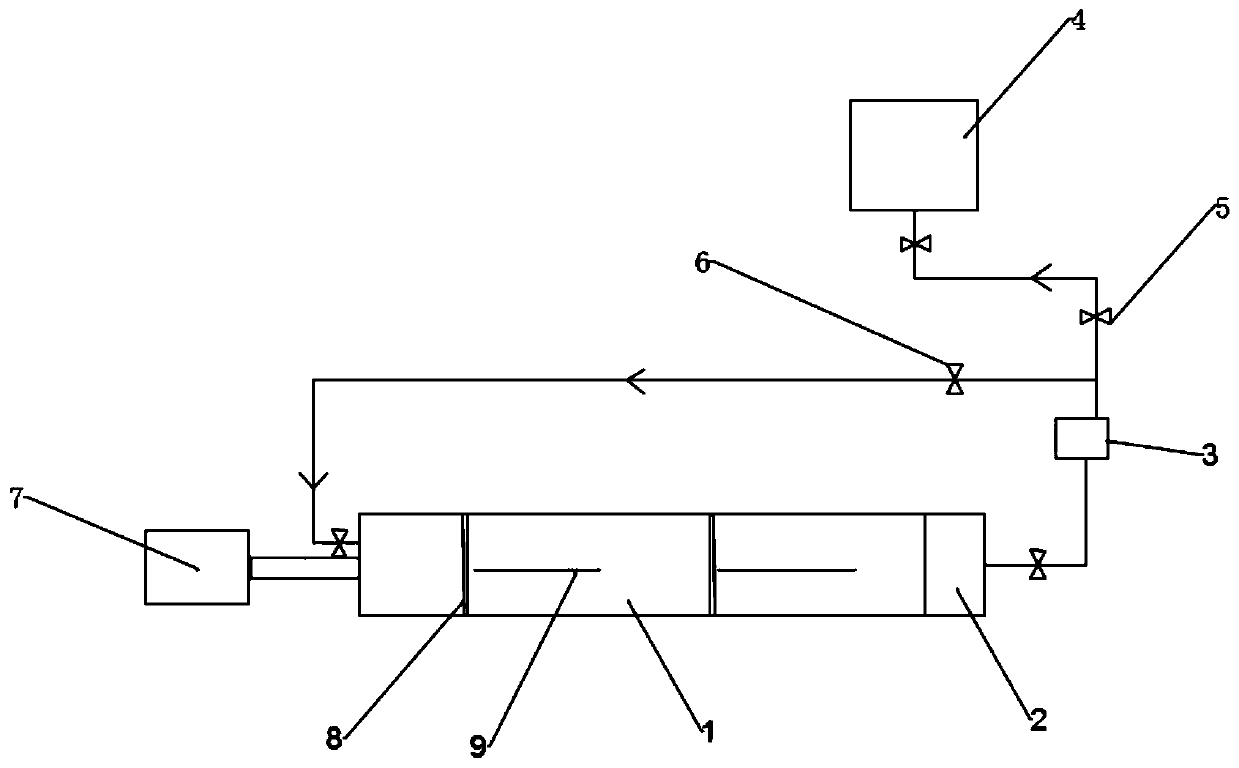

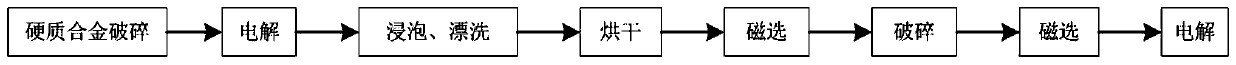

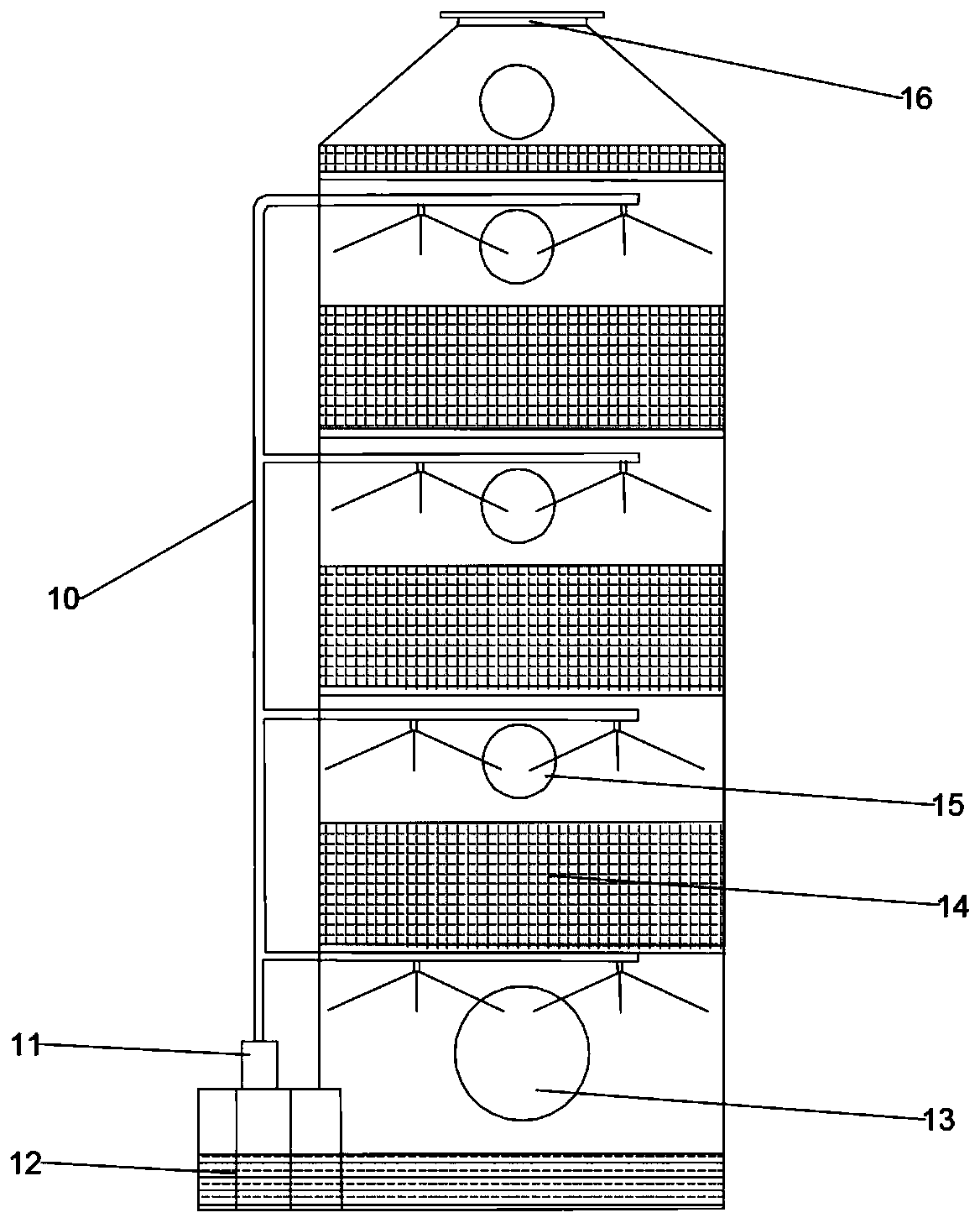

[0035] Use a ball mill to crush the hard scrap alloy. When the cobalt content of the hard scrap alloy is less than 11%, the crushed particle size is 4mm. When the cobalt content is greater than 11%, the crushed particle size is 8mm. Put it into the small electrolysis box and place it in the electrolytic tank for electrolysis, add hydrochloric acid with a concentration of 2.0mol / L as the electrolyte, use a 9kw750A rectifier, control the voltage in the small electrolysis box to 0.85V, and the current to 10A, start the heater, and control the electrolyte The temperature is 43°C, the electrolyte is continuously circulated under the action of the acid-resistant pump, and the cobalt is electrolyzed to form a cobalt chloride solution, Co+2HCl=CoCl 2 +H 2 , the non-electrolyzed alloy particles remain in the small electrolytic frame; when the specific gravity of cobalt chloride in the electrolytic solution reaches 1.24kg / dm 3 At the same time, the electrolytic solution containing coba...

Embodiment 2

[0037] Use a ball mill to crush the hard scrap metal. When the cobalt content of the hard scrap alloy is less than 11%, the crushed particle size is 2mm. When the cobalt content is greater than 11%, the crushed particle size is 6mm. Put it into the small electrolysis box and place it in the electrolytic tank for electrolysis, add hydrochloric acid with a concentration of 2.2mol / L as the electrolyte, use a 9kw750A rectifier, control the voltage in the small electrolysis box to 1V, and the current to 10A, start the heater, and control the flow of the electrolyte The temperature is 40°C, the electrolyte is continuously circulated under the action of the acid-resistant pump, and the cobalt is electrolyzed to form a cobalt chloride solution, Co+2HCl=CoCl 2 +H 2 , the non-electrolyzed alloy particles remain in the small electrolytic frame; when the specific gravity of cobalt chloride in the electrolytic solution reaches 1.20kg / dm 3 At the same time, the electrolytic solution contai...

Embodiment 3

[0039] Use a ball mill to crush the hard scrap alloy. When the cobalt content of the hard scrap alloy is less than 11%, the crushed particle size is 6mm. When the cobalt content is greater than 11%, the crushed particle size is less than 10mm. Put it into the small electrolysis box and place it in the electrolytic cell for electrolysis, add hydrochloric acid with a concentration of 2.4mol / L as the electrolyte, use a 9kw 750A rectifier, control the voltage in the small electrolysis box to 0.9V, and the current to 10A, start the heater, control The temperature of the electrolyte is 45°C, and the electrolyte is continuously circulated under the action of the acid-resistant pump, and the cobalt is electrolyzed to form a cobalt chloride solution, Co+2HCl=CoCl 2 +H 2 , the non-electrolyzed alloy particles remain in the small electrolytic frame; when the specific gravity of cobalt chloride in the electrolytic solution reaches 1.15kg / dm 3 At the same time, the electrolytic solution c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com