Precast beam timing maintenance device

A technology of prefabricated beams and pipes, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome operation, failure to automatically close, inconvenient maintenance of prefabricated beams, etc., and achieve the effect of sufficient spraying and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

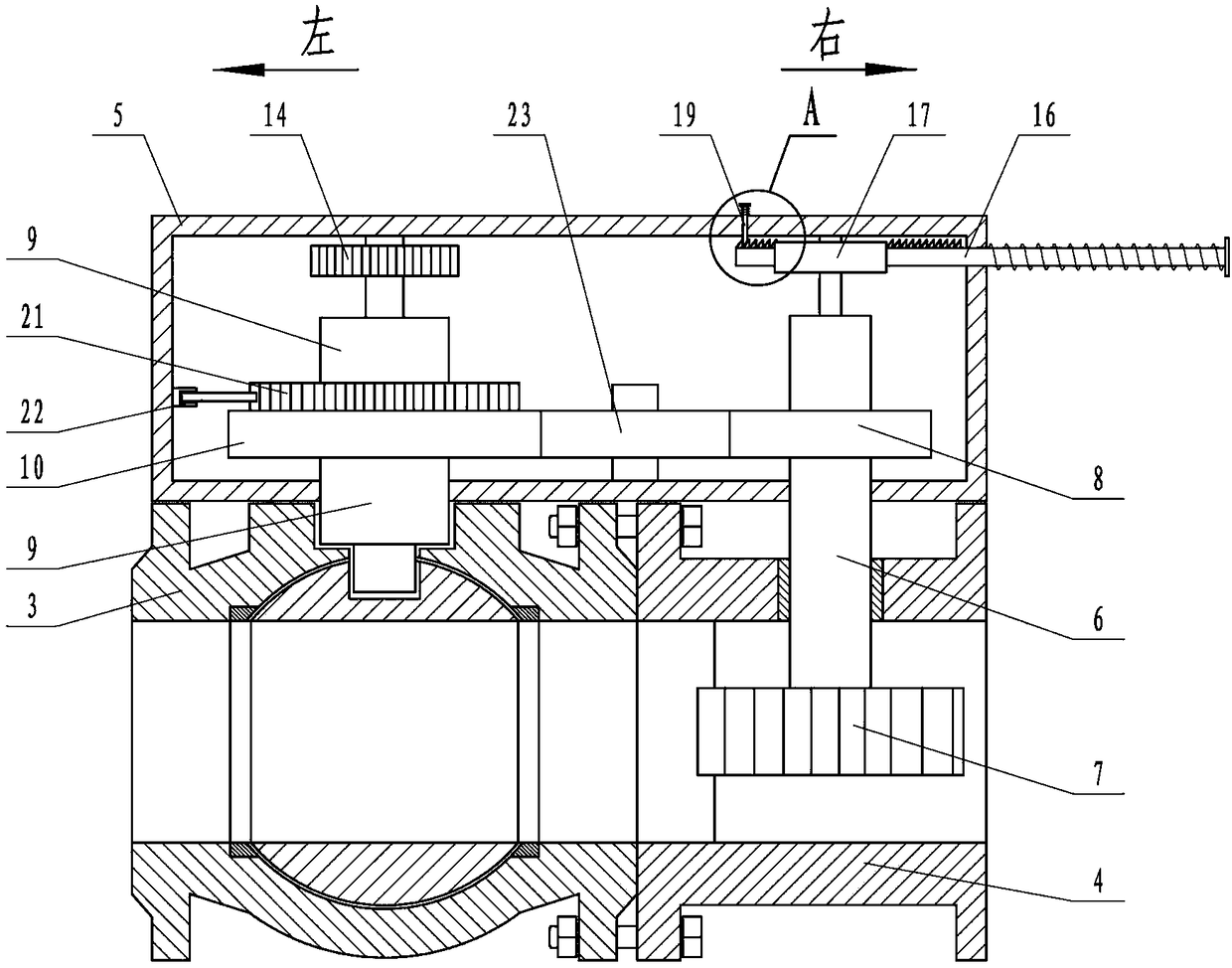

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

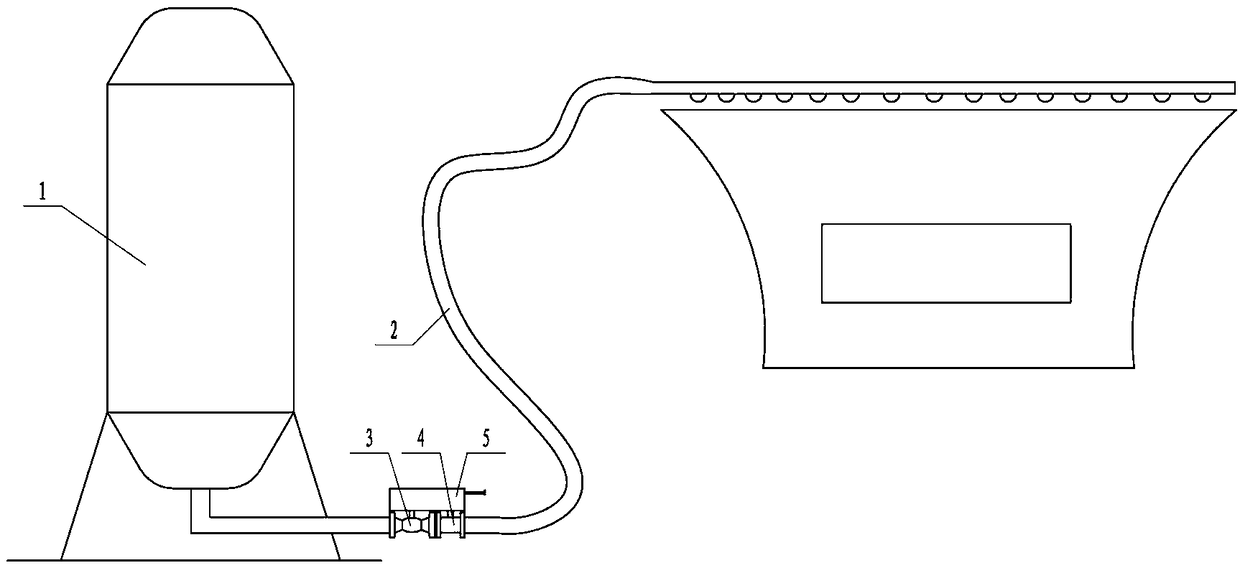

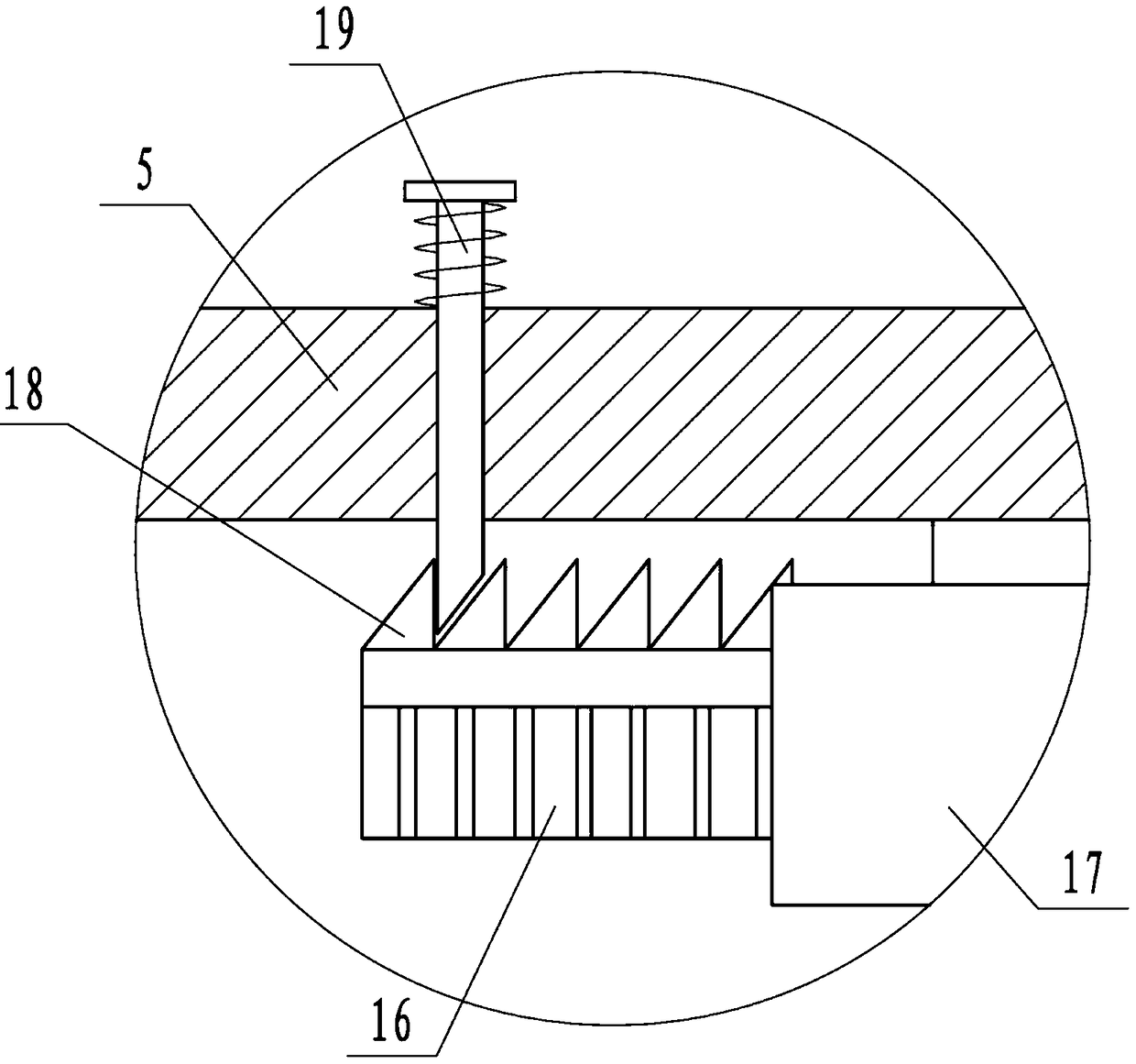

[0017] Depend on Figure 1 to Figure 8 Given, the present invention comprises a water supply system 1, a pipeline 2, a plurality of shower heads installed on the pipeline 2 and a timing valve, the timing valve includes a ball valve 3 and a housing 4 communicated with the ball valve 3, the ball valve 3 and the housing 4 A casing 5 is installed above; a vertically rotatable rotating shaft 6 is installed on the casing 4, an impeller 7 placed in the casing 4 and a driving wheel 8 placed in the casing 5 are installed on the rotating shaft 6, the rotating shaft 6 and the driving A mechanical overload device is installed between the wheels 8; a driven wheel 10 is set on the valve stem 9 of the ball valve 3, and the driven wheel 10 can only rotate in one direction and a torsion spring 11 is installed between the valve stem 9; ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com