Integrated fixture and welding method for 5G SFP package type optical transceiver module

A technology of optical transceiver module and welding method, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of reducing the influence of welding quality, low proficiency and operation technical requirements, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

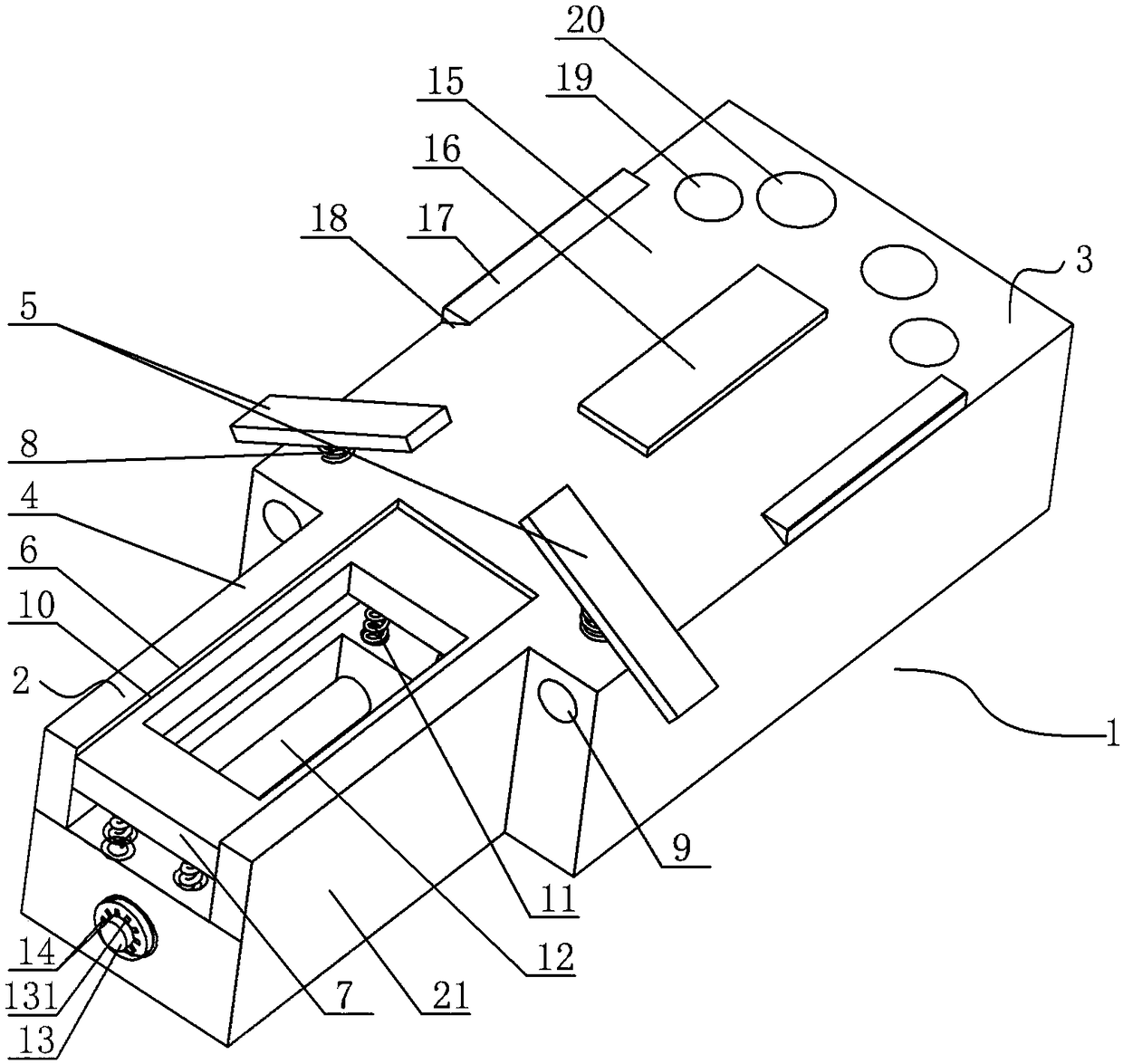

[0035] An integrated fixture for welding 5G SFP-packaged optical transceiver modules, see figure 1 : It includes a working base 1, a soft board welding part 2 and an optical device welding part 3 respectively arranged at the upper end positions of both ends of the working base 1 in the length direction, and the soft board welding part 2 is used for connecting the PCB circuit board and the PCB The flexible board is pre-fixed and pre-soldered, and the optical device welding part 3 welds the semi-finished device and optical device completed by the flexible board welding part 2 into a complete 5G SFP package optical transceiver module device.

[0036] The working base 1 is made of aluminum alloy, which can conduct the device and the ground;

[0037]The soft board welding part 2 specifically includes a welding operation table 4 and a welding combination fixture. The welding combination fixture specifically includes a pair of reversible pressure plates 5. The welding operation table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com