High-load precious metal monatomic catalyst as well as preparation method and application of high-load precious metal monatomic catalyst

A high-load, precious metal technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as reducing the electrocatalytic performance of materials, and achieve short cycle times, improved catalytic performance, and good dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] To prepare the carbon-supported single-atom platinum catalyst, 100 mg (0.1 g) of nitrogen-doped carbon black was thoroughly ground, put it into a 500 mL beaker, added 4 mL of 0.01 M chloroplatinic acid solution, and added deionized water to 250 mL. The chloroplatinate ions are fully adsorbed on the carbon carrier after being treated by stirring, ultrasonic, shaking and vacuum environment. After that, the separation operation is carried out. First, the above solution is extracted, then washed with deionized water, washed with potassium hydroxide several times, and then washed with deionized water until neutral. Collect the filter cake, dry it naturally, and grind it for later use. Spread the above powder on a glass plate, select a UV lamp with a power of 10 W and a wavelength of 254 nm, make the distance between the UV lamp and the sample 10 cm, and irradiate for 1 hour to obtain a final single-atom platinum catalyst loading of 6.9 wt%.

Embodiment 2

[0034] To prepare a carbon-supported single-atom platinum catalyst, 100 mg of nitrogen-doped graphene was thoroughly ground, put it into a 500 mL beaker, added 6 mL of 0.01 M chloroplatinic acid solution, and added deionized water to 250 mL. The chloroplatinate ions are fully adsorbed on the carbon carrier after being treated by stirring, ultrasonic, shaking and vacuum environment. After that, the separation operation is carried out. First, the above solution is extracted, then washed with deionized water, washed with potassium hydroxide several times, and then washed with deionized water until neutral. Collect the filter cake, dry it naturally, and grind it for later use. Spread the above powder on a glass plate, select a UV lamp with a power of 10 W and a wavelength of 254 nm, make the distance between the UV lamp and the sample 10 cm, and irradiate for 1 hour to obtain a final single-atom platinum catalyst loading of 9.8 wt%.

Embodiment 3

[0036]To prepare a carbon-supported single-atom platinum catalyst, 100 mg of nitrogen-doped carbon black was thoroughly ground, put it into a 500 mL beaker, added 0.1 mL of 0.01 M chloroplatinic acid solution, and added deionized water to 250 mL. The chloroplatinate ions are fully adsorbed on the carbon carrier after being treated by stirring, ultrasonic, shaking, vacuum environment and the like. After that, the separation operation is carried out. First, the above solution is extracted, then washed with deionized water, washed with potassium hydroxide several times, and then washed with deionized water until neutral. Collect the filter cake, dry it naturally, and grind it for later use. Spread the above powder on a glass plate, select a UV lamp with a power of 10 W and a wavelength of 254 nm, make the distance between the UV lamp and the sample 10 cm, and irradiate for 1 hour to obtain a final single-atom platinum catalyst loading of 0.13 wt%.

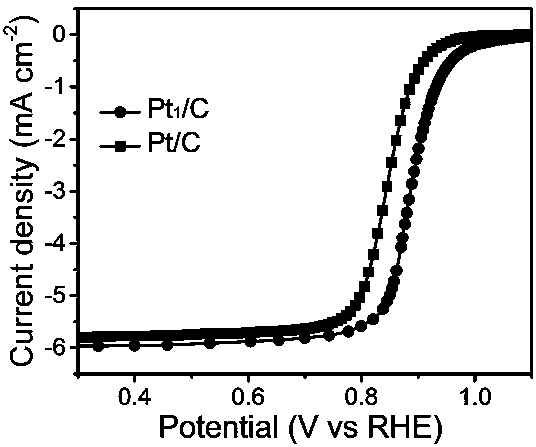

[0037] figure 1 Under the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com