Method for extracting uranium by utilizing photocatalysis technology under visible light

A photocatalytic and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor selectivity, complicated operation, and difficult elution of adsorption methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

[0022] Step 1: Put C 3 N 4 Put 10g of melamine in a crucible, heat up to 550°C in a muffle furnace at a rate of 2°C / min, and keep it for 4 hours to obtain a light yellow blocky solid, which is ground for later use;

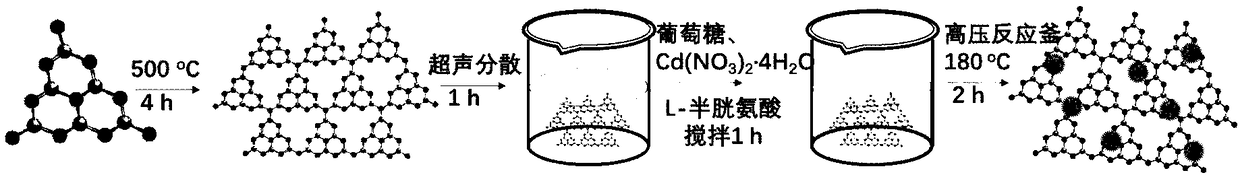

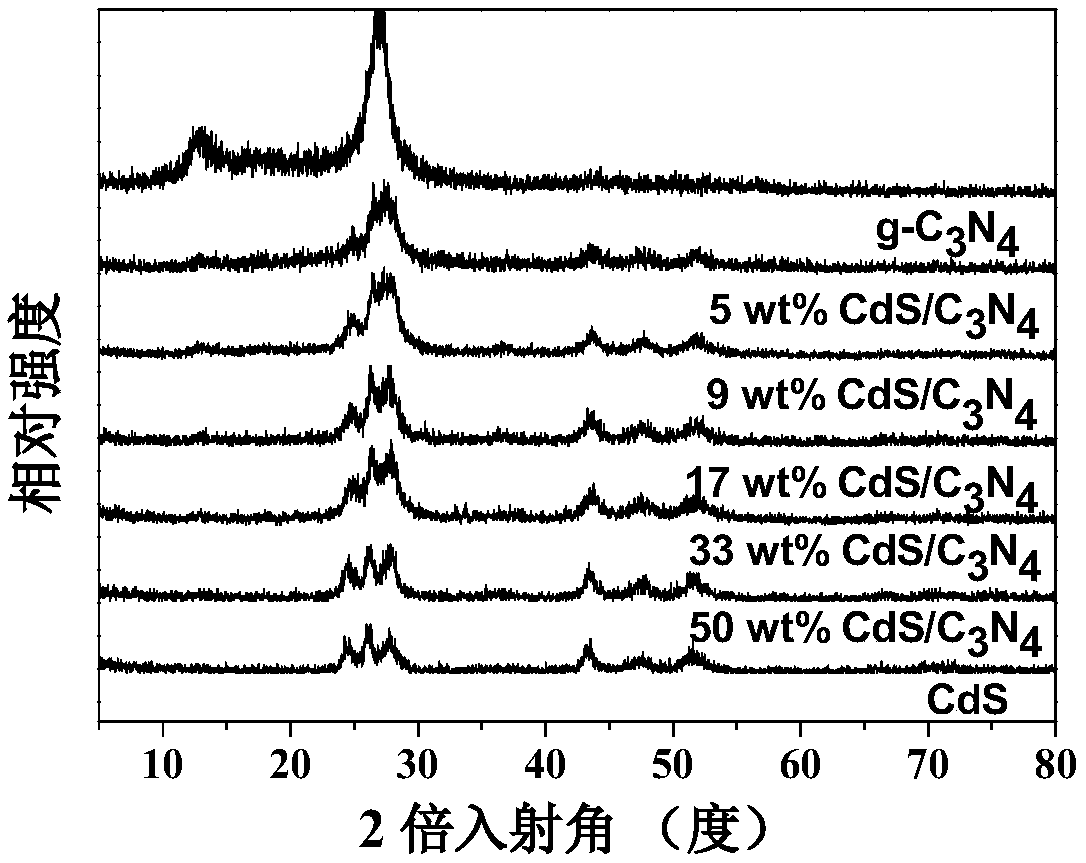

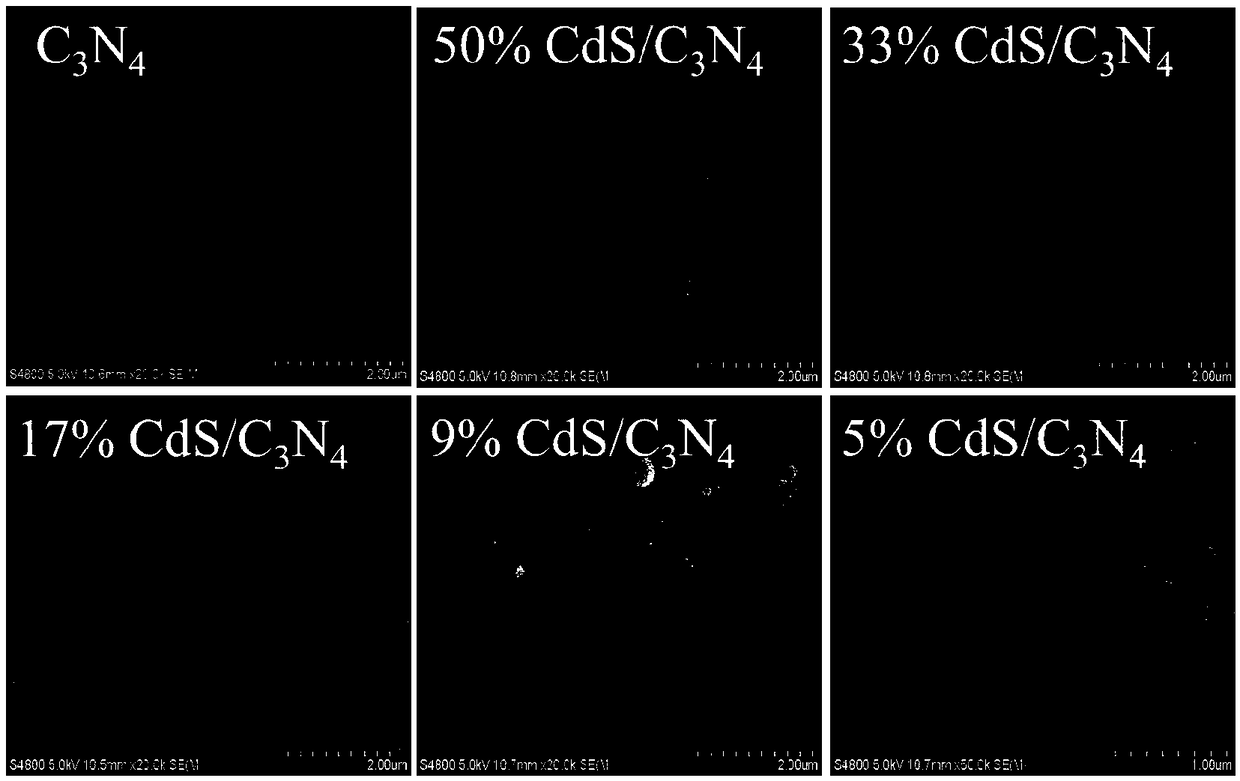

[0023] Step 2: CdS / C 3 N 4 Preparation: Weigh 0.2g light yellow blocky solid and dissolve it in 200ml ultrapure water, ultrasonically disperse it for 1h, add 0.4g glucose, 0.62g Cd(NO 3 ) 2 4H 2 O, magnetically stirred for 4 hours, added 1.18g L-cysteine and continued to stir for 1 hour, moved into a high-pressure reactor and placed in a 180-degree oven at a constant temperature for 2 hours, cooled and filtered, washed several times with ultrapure water and absolute ethanol, and freeze-dried for 12 hours , milled to obtain CdS / C with 50% CdS loading 3 N 4 composite materials;

[0024] Step 3: In the performance test experiment, add 0.015g CdS / C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com