Photocuring electrolyte, electrochromic device and preparation method thereof

An electrochromic device and electrochromic layer technology, which can be applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems such as the difficulty of liquid electrolyte encapsulation, and achieve the effects of low cost, fast encapsulation, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

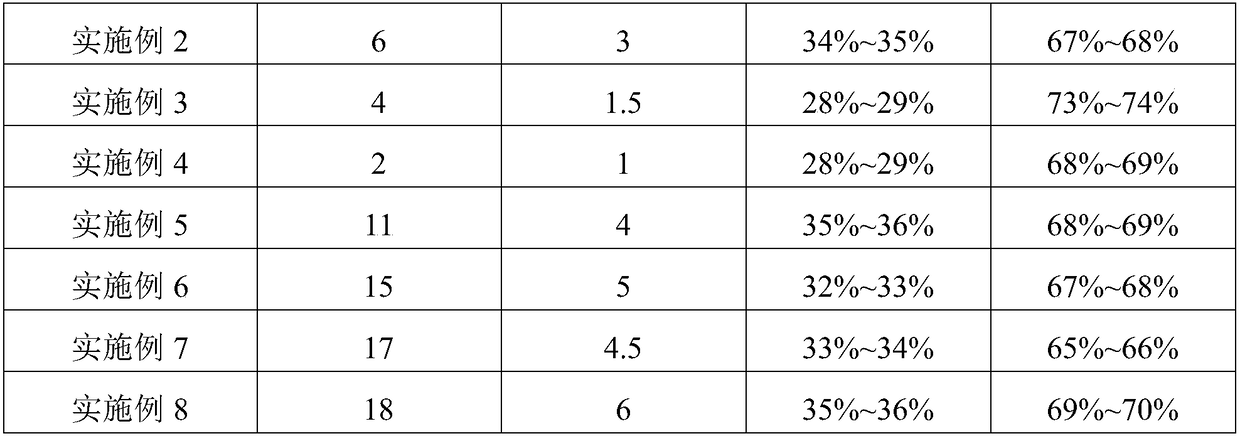

Examples

Embodiment 1

[0053] An electrochromic device comprising:

[0054] Indium tin oxide transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 100μm,

[0055] Tungsten trioxide electrochromic layer with a thickness of 10 μm,

[0056] Photocurable gel electrolyte layer with a thickness of 25 μm: 10g ethylene carbonate, 20g propylene carbonate, 10g photocurable polyester acrylic resin, 10g poly(vinylidene fluoride-hexafluoropropylene), 10g lithium trifluoromethanesulfonate, 0.02 g 2-hydroxymethylphenylpropan-1-one, 0.5 g silica.

[0057] The preparation method of the electrochromic device comprises the following steps:

[0058] (1) Indium tin oxide transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 100μm is unwound by the unwinding system, and passes through the tungsten trioxide ink feeding system (the coating method of the feeding system can be dimples, slits , letterpress, roller coating, but not limited to the above four coating...

Embodiment 2

[0064] An electrochromic device comprising:

[0065] Nano-silver wire transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 125μm,

[0066] Indium tin oxide transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 100μm,

[0067] Tungsten trioxide electrochromic layer with a thickness of 20 μm,

[0068] Photocurable gel electrolyte layer with a thickness of 25 μm: 15g ethylene carbonate, 15g propylene carbonate, 20g photocurable polyurethane acrylic resin, 25g poly(vinylidene fluoride-hexafluoropropylene), 5g lithium trifluoromethanesulfonate, 0.01g 2-Hydroxymethylphenylpropan-1-one, 3 g of silicon dioxide.

[0069] The preparation method of the electrochromic device comprises the following steps:

[0070] (1) Nano-silver wire transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 125μm is unwound by the unwinding system,

[0071] After the tungsten trioxide ink feeding system (the coa...

Embodiment 3

[0076] An electrochromic device comprising:

[0077] Indium tin oxide transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 100μm,

[0078] A poly-3,4-ethylenedioxythiophene electrochromic layer with a thickness of 10 μm,

[0079] Photocurable gel electrolyte layer with a thickness of 25 μm: 10g ethylene carbonate, 20g propylene carbonate, 10g photocurable polyester acrylic resin, 10g polyacrylonitrile, 5g polymethyl acrylate, 10g lithium perchlorate, 0.05g 2-iso Propylthioxanthone, 0.5g LiAlO 2 .

[0080] The preparation method of the electrochromic device comprises the following steps:

[0081] (1) The indium tin oxide transparent conductive PET film with a square resistance of 90Ω / □ and a thickness of 100 μm is unwound by the unwinding system, and passes through the poly-3,4-ethylenedioxythiophene ink feeding system (the coating method of the feeding system can be It is one of micro-concave, slit, letterpress, and roller coating, but not l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com