A steam supply system for a cigarette factory

A steam supply and cigarette factory technology, applied in steam generation, steam generation method using pressure combustion, preheating, etc., can solve the problems of uneven distribution of steam use, unstable pressure, high cost, etc., and achieve various forms of use Flexibility, improve utilization efficiency, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

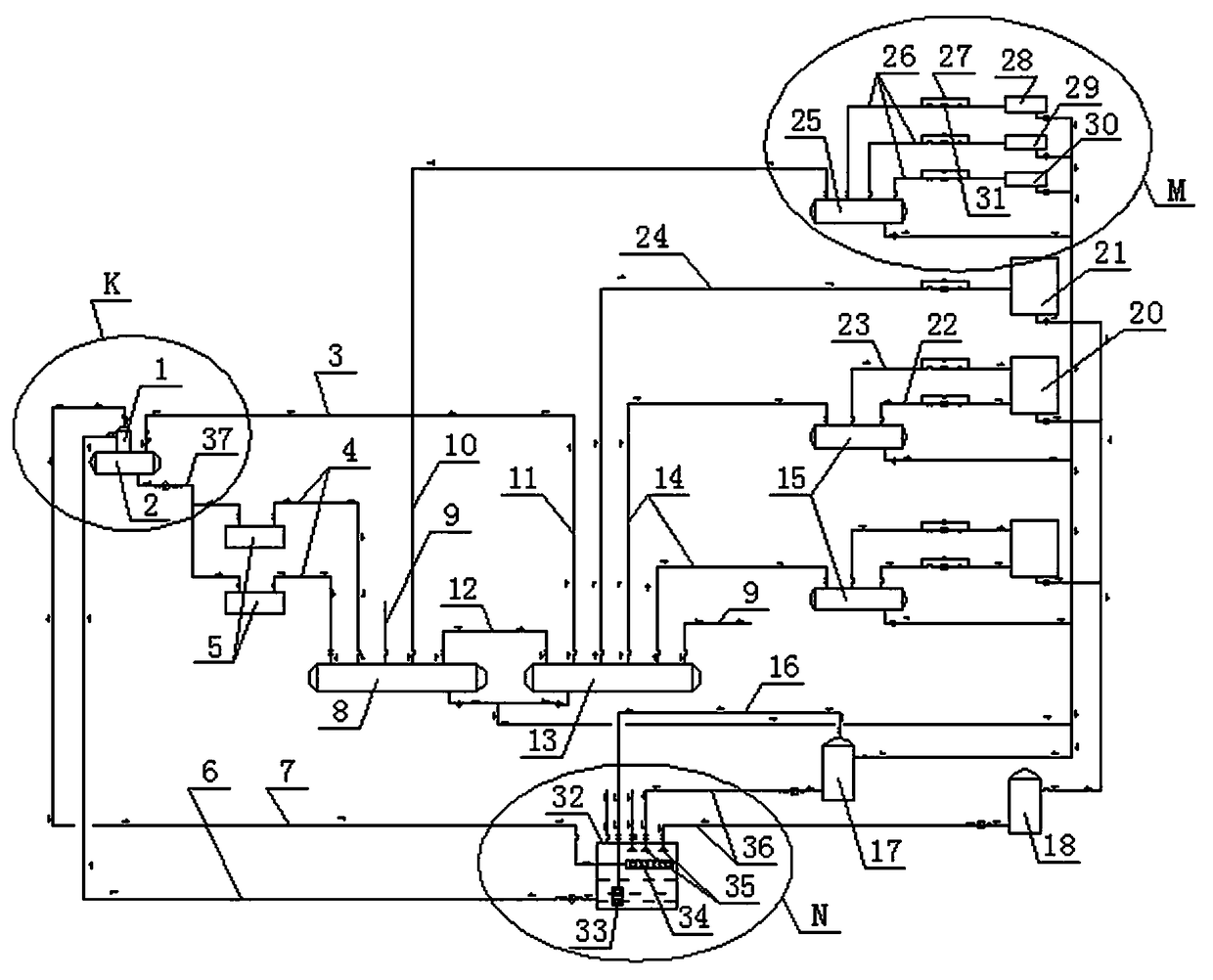

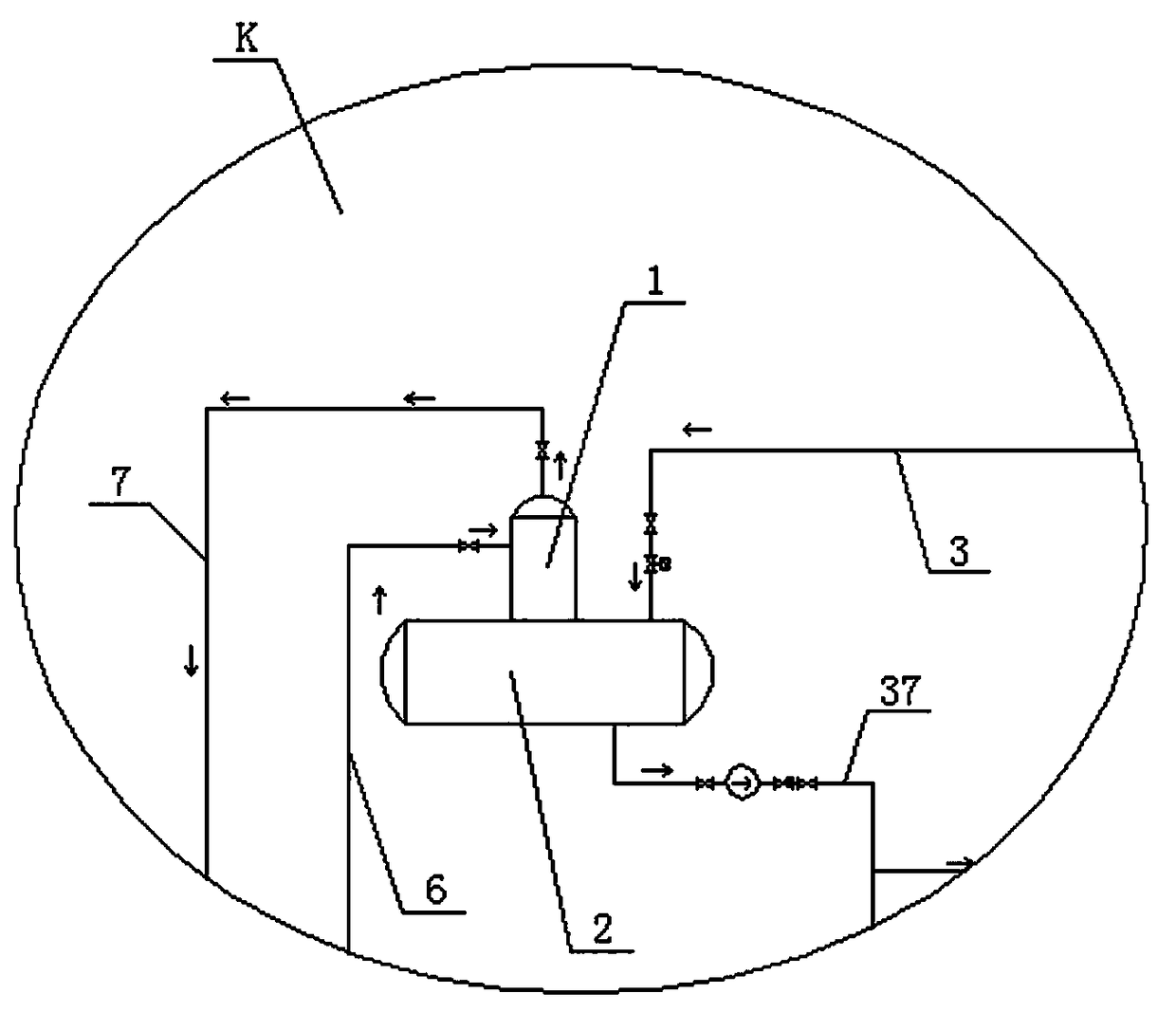

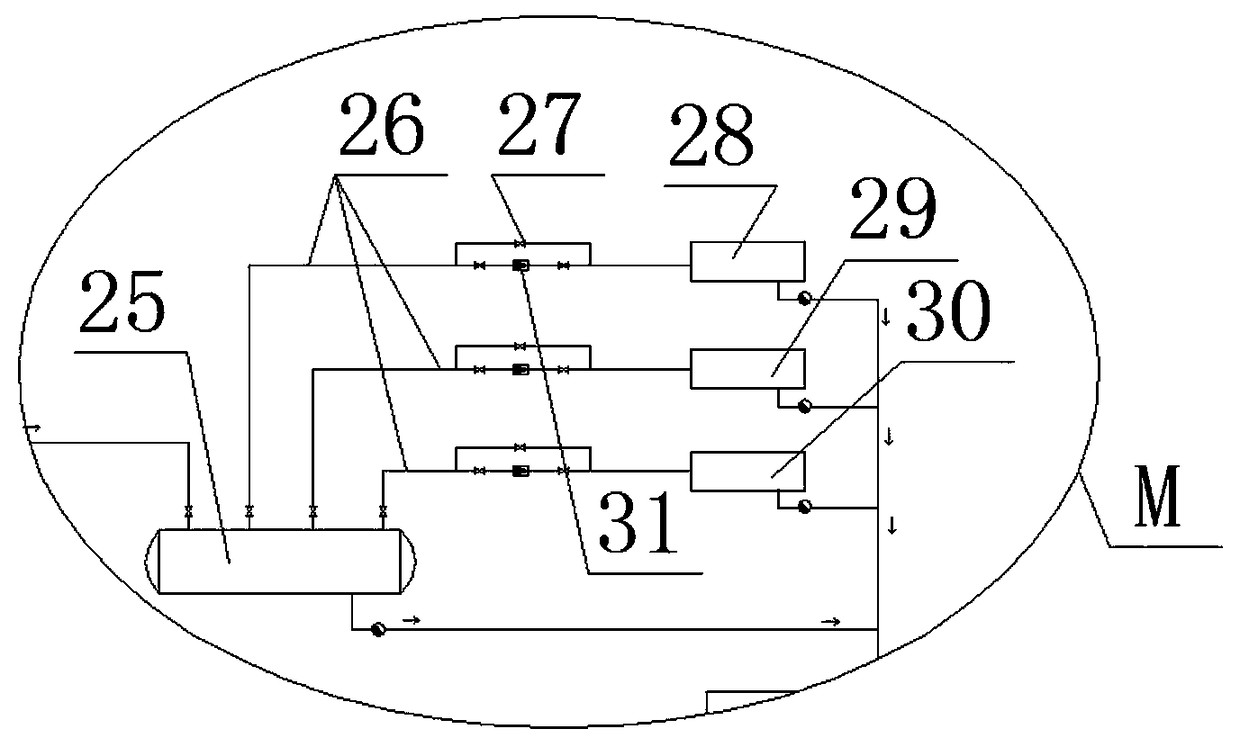

[0016] like Figure 1 to Figure 4 As shown, a cigarette factory steam supply system includes a boiler 5, a high-pressure sub-cylinder 8, a low-pressure sub-cylinder 13, a silk production sub-cylinder 25, a heat exchanger 21, an air-conditioning sub-cylinder 15, a high-pressure condensed water recovery tank 17, The low-pressure condensed water recovery tank 18 and the condensed water tank 32, the boiler 5 is connected with the high-pressure sub-cylinder 8 through the first pipeline 4, the high-pressure sub-cylinder 8 is connected with the low-pressure sub-cylinder 13 through the second pipeline 12, and the high-pressure sub-cylinder 8 passes through the first The three pipelines 10 are connected with the sub-cylinder 25 for silk production, the low-pressure sub-cylinder 13 is connected with the heat exchanger through the fourth pipeline 24, and the low-pressure sub-cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com