A method for preparing printing paper with moisture-proof function

A technology for printing paper and functions, which is applied in the field of printing paper with moisture-proof function, can solve the problems of unsuitability for printer printing, ink is not easy to form, and printing is inconvenient, and achieves the effect of enhancing surface energy, enhancing moisture-proof performance, and improving moisture-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of printing paper preparation method with moisture-proof function of the present embodiment, comprises the following steps:

[0025] Step 1: Disperse the starch into water, prepare a slurry with a concentration of 30%, then add 0.01% starch branching enzyme, raise the temperature to 35°C, react for 15 minutes, then add concentrated sulfuric acid to it for 4 minutes, and then add poly Vinyl alcohol, continue to stir for 12min, cool to room temperature, and set aside;

[0026] Step 2: Add the starch slurry prepared in Step 1 into the wood pulp and straw pulp mixture, add while stirring, then add 6% of the total weight of inorganic thickening agent, pretreated hydrophobic zeolite, hydroxypropyl cellulose, and stir The rotation speed was increased to 155r / min, the stirring time was 25min, and then papermaking, pressing, drying, and coiling were performed to obtain printing base paper, and then the printing base paper was sprayed with moisture-proof additives and then...

Embodiment 2

[0035] A kind of printing paper preparation method with moisture-proof function of the present embodiment, comprises the following steps:

[0036] Step 1: Disperse the starch into water, prepare a slurry with a concentration of 40%, then add 0.04% starch branching enzyme, raise the temperature to 45°C, react for 15-25min, then add concentrated sulfuric acid to it for 6min, and then Add polyvinyl alcohol, continue to stir for 16 minutes, cool to room temperature, and set aside;

[0037] Step 2: Add the starch slurry prepared in Step 1 into the wood pulp and straw pulp mixture, add while stirring, then add 10% of the total weight of inorganic thickening agent, pretreated hydrophobic zeolite, hydroxypropyl cellulose, and stir The rotation speed was increased to 165r / min, and the stirring time was 35min. Then, papermaking, pressing, drying, and coiling were performed to obtain printing base paper. Then, the printing base paper was sprayed with moisture-proof additives and dried to...

Embodiment 3

[0046] A kind of printing paper preparation method with moisture-proof function of the present embodiment, comprises the following steps:

[0047] Step 1: Disperse the starch in water, prepare a slurry with a concentration of 35%, then add 0.025% starch branching enzyme, raise the temperature to 40°C, react for 20 minutes, then add concentrated sulfuric acid to it for 5 minutes, and then add poly Vinyl alcohol, continue to stir for 14min, cool to room temperature, and set aside;

[0048] Step 2: Add the starch slurry prepared in Step 1 into the wood pulp and straw pulp mixture, add while stirring, then add 8% of the total weight of inorganic thickening agent, pretreated hydrophobic zeolite, hydroxypropyl cellulose, and stir The rotation speed is increased to 160r / min, the stirring time is 30min, and then papermaking, pressing, drying, and coiling are performed to obtain printing base paper, and then the printing base paper is sprayed with moisture-proof additives and dried to ...

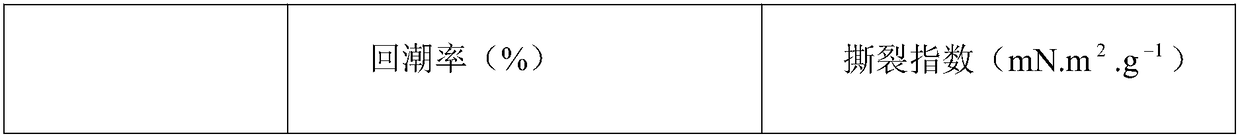

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com