A method for rapidly preparing ultra-thin ceramic sheets

A special ceramic, ultra-thin technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve problems such as a single ultra-thin ceramic sheet, to expand the application mode and scope, short production cycle, prospects huge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

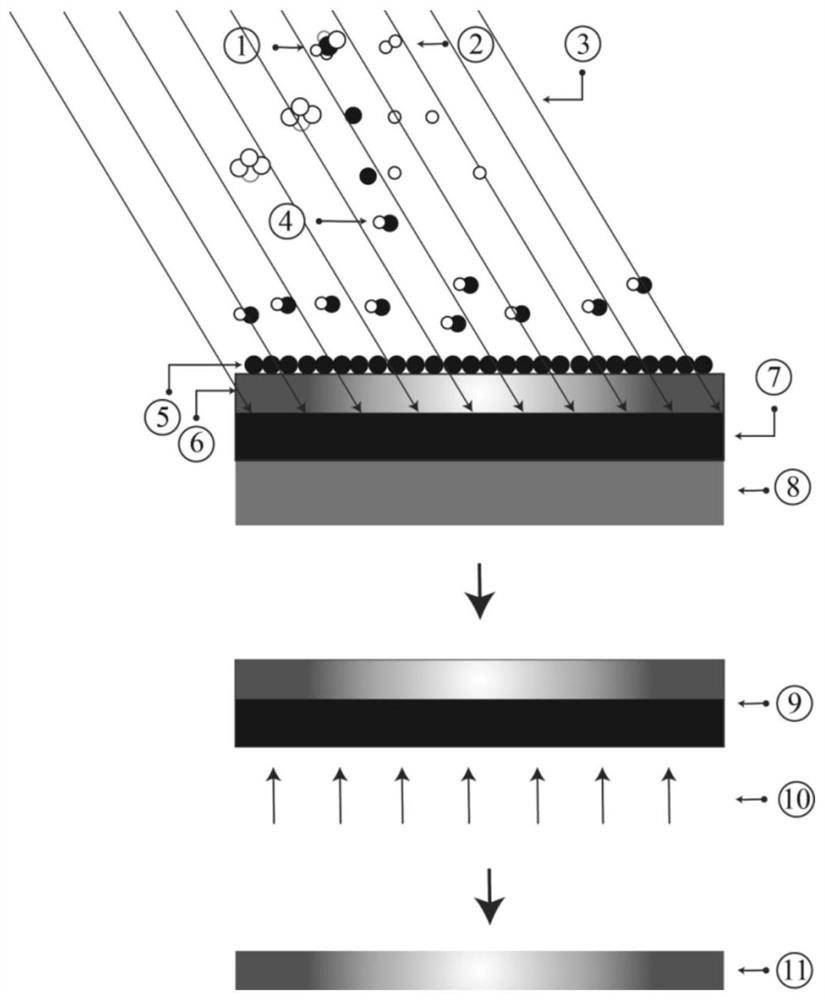

Method used

Image

Examples

Embodiment 1

[0034] The method for rapidly preparing ultra-thin AlN special ceramic sheets with a thickness of 500 μm on a graphite substrate with a thickness of 50 mm by using LCVD technology is as follows:

[0035] (1) Clean and dry the graphite substrate according to the above method, place it on the heating platform substrate base of the laser chemical vapor deposition device, extract the vacuum to below 800Pa, and then preheat the substrate to 773K. Take appropriate amount of Al(acac) 3 (Aluminum triacetylacetonate) was dissolved in 200 mL of tetrahydrofuran solvent, and the resulting solution was added to the raw material tank.

[0036] (2) Turn on the laser, set the output power to 180W, and the continuous Nd:YAG laser (wavelength: 1064nm) irradiates the surface of the substrate through the quartz window of the equipment, forming a spot of about 25mm. The temperature of the substrate is measured in real time through the thermocouple on the back of the heating stage. After the tempe...

Embodiment 2

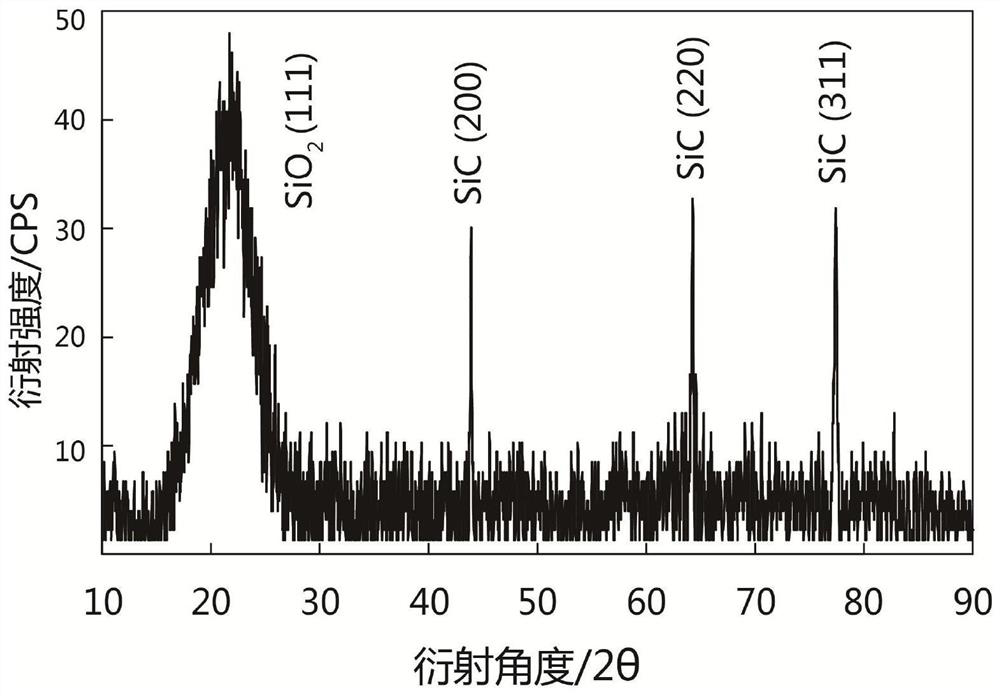

[0040] The method of quickly preparing SiC ultra-thin special ceramic sheets with a thickness of 450 μm on a graphite substrate with a thickness of 100 mm by using LCVD technology is as follows:

[0041] (1) Firstly, the graphite substrate was placed in acetone, absolute ethanol, and deionized water for 20 minutes by ultrasonic vibration cleaning, and then the cleaned substrate was fully dried in an oven. Put the cleaned graphite substrate on the heating platform substrate seat of the laser chemical vapor deposition device, vacuumize to reduce the pressure to below 800Pa, and then preheat the substrate to 773K. Take an appropriate amount of hexamethyldisilane (C 6 h 18 Si 2 ) was dissolved in about 200 mL of tetrahydrofuran (Tetrahydrofuran; THF) solvent, and the resulting solution was added to the raw material tank.

[0042] (2) Turn on the laser, set the output power to 180W, and the continuous Nd:YAG laser (wavelength is 1064nm) shines on the surface of the substrate thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com