A method for microwave heating reduction-magnetic separation dephosphorization of high phosphorus hematite

A technology of microwave heating and hematite, which is applied in the direction of fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of easy fusion of reactors and large damage to reactors, and achieve simple and easy crushing and ensure iron grades , Improve the effect of reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

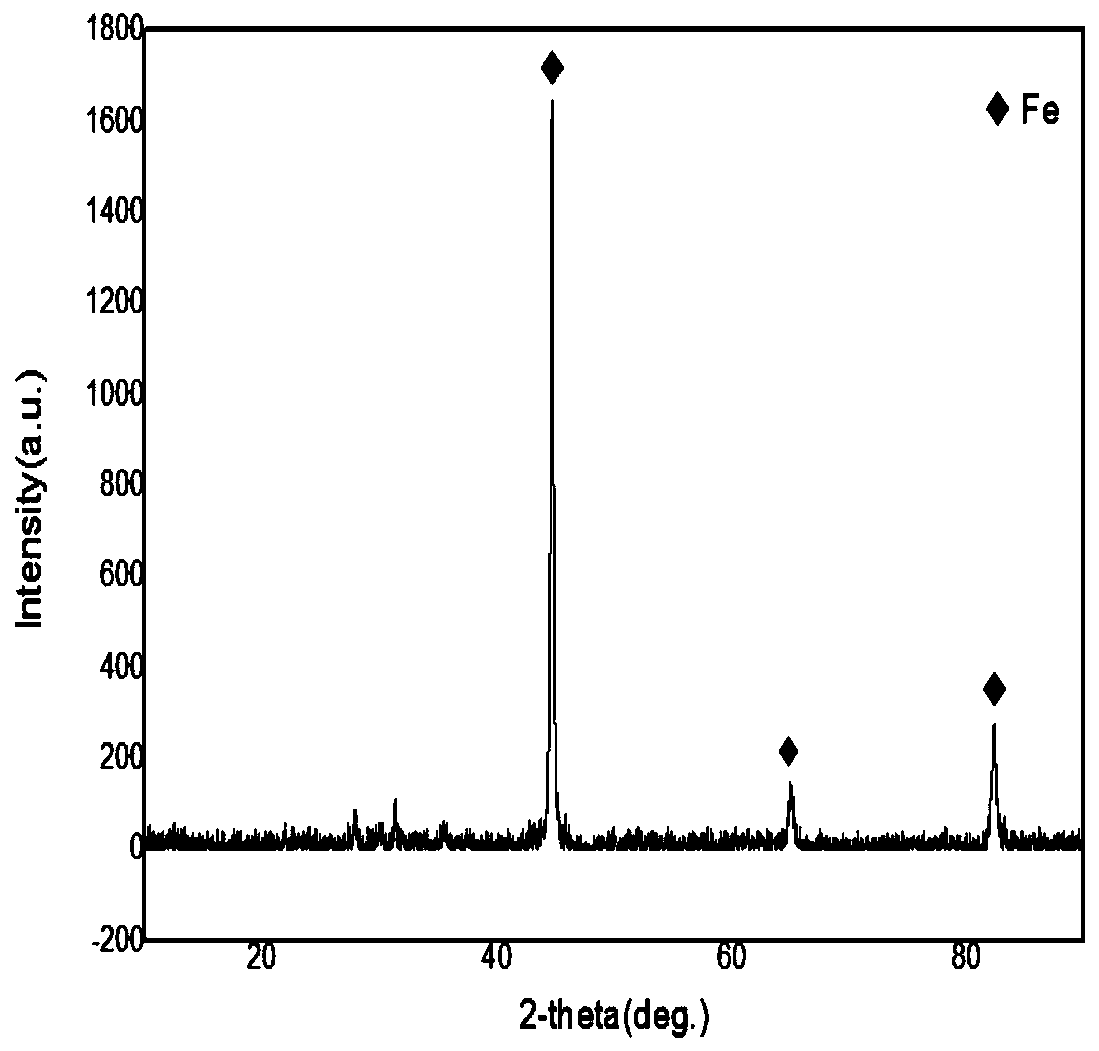

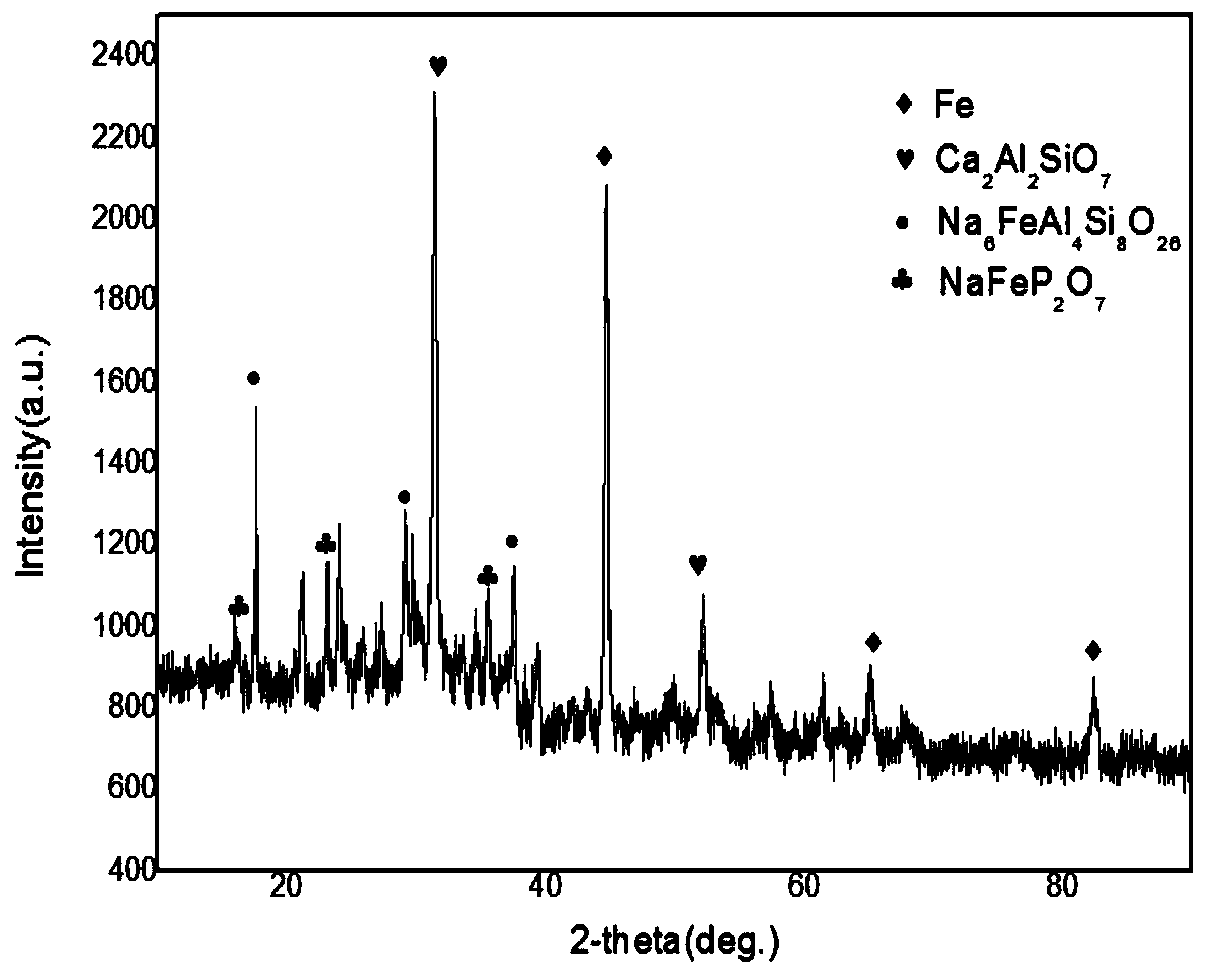

Embodiment 1

[0042] A high-phosphorus oolitic hematite ore contains 43% iron and 0.87% phosphorus. Phosphorus is mainly stored in collophanite. The material ratio of the high-phosphorus oolitic hematite reduction is that the ratio of high-phosphorus hematite to mixed coal powder (anthracite coal powder and coconut shell carbon powder is mixed at 3:1) is 1:0.1 by weight, and the alkali Degree: 0.4, the ratio of binder is 4% by weight, the ratio of dephosphorization agent is 7.5% by weight, and the type of dephosphorization agent is Na 2 CO 3 , CaCl 2 Mixed at 1:1, the composite catalyst is 3% by weight, and the perforation density is 5 holes / cm 2 . Place the prepared pellets in a microwave heating furnace and heat them from room temperature to 900°C at a controlled heating rate of 17°C / min, then from 900°C to 1100°C at a heating rate of 10°C / min, and then keep warm for 10 minutes After taking it out, it is immediately placed in hot water for heat quenching treatment, so as to facilitate...

Embodiment 2

[0044] A high-phosphorus oolitic hematite ore contains 43% iron and 0.87% phosphorus. Phosphorus is mainly stored in collophanite. The material proportion of this high-phosphorus oolitic hematite reduction is that the proportioning ratio of high-phosphorus hematite and mixed coal powder (anthracite coal powder and coconut shell carbon powder are mixed at 3.5:1) is 1:0.15 by weight, alkali Degree: 1.0, the ratio of binder is 4% by weight, the ratio of dephosphorization agent is 7.5% by weight, and the type of dephosphorization agent is Na 2 CO 3 , the composite catalyst is 5% by weight, and the perforation density is 6 holes / cm 2 . Place the prepared pellets in a microwave heating furnace and heat from room temperature to 900°C at a controlled heating rate of 19°C / min, then from 900°C to 1200°C at a heating rate of 12°C / min, and then keep warm for 15 minutes Take it out and put it in hot water immediately for heat quenching treatment. Afterwards, put the reduced pellets int...

Embodiment 3

[0046] A high-phosphorus oolitic hematite ore contains 46.4% iron and 0.69% phosphorus. Phosphorus is mainly stored in fluorapatite. The material proportion of this high-phosphorus oolitic hematite reduction is that the proportioning ratio of high-phosphorus hematite and coal powder (anthracite coal powder and coconut shell carbon powder are mixed at 3.2:1) is 1:0.18 by weight, and the alkalinity For: 1.2, the proportioning of binder is 3% by weight percentage, the proportioning of dephosphorization agent is 5% by weight percentage, the kind of dephosphorization agent is CaCl 2 and Na 2 SO 4 , mixed by 4:1, the composite catalyst is 2% by weight, and the perforation density is 8 holes / cm 2 . Place the prepared pellets in a microwave heating furnace and heat from room temperature to 900°C at a controlled heating rate of 20°C / min, then from 900°C to 1250°C at a heating rate of 13°C / min, and then continue to keep warm for 3 minutes Take it out and put it in hot water immediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com