Random distributed Rayleigh feedback fiber laser based on double-cladding weak ytterbium-doped fiber

A technology of fiber lasers and ytterbium-doped fibers, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems that a single fiber cannot provide distributed active gain and random distributed Rayleigh feedback at the same time, and achieve the suppression Effects of non-linear effects, reduced requirements, lower lasing threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

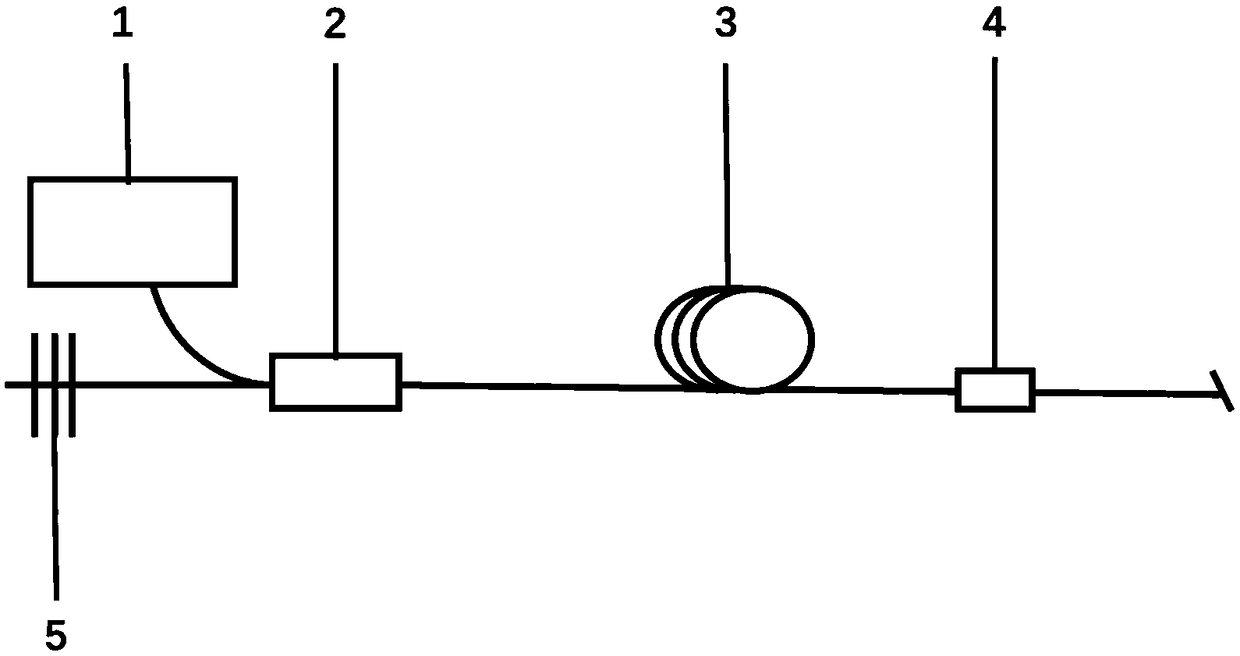

[0058] A randomly distributed Rayleigh feedback fiber laser based on a double-clad weakly doped ytterbium fiber, including a pump laser source 1, a pump beam combiner 2 and a cladding power stripper 4, including for simultaneously realizing distributed active gain and The double-clad weakly doped ytterbium fiber 3 with randomly distributed Rayleigh feedback, the output end of the pump combiner 2 is connected to one end of the double-clad weakly doped ytterbium fiber 3, and the other end of the double-clad weakly doped ytterbium fiber 3 is connected to the cladding The input end of the layer power stripper 4 is connected, and the double-clad weakly doped ytterbium fiber 3 includes an outer cladding composed of pure silicate, an inner cladding of germanium silicate doped with a certain concentration of germanium ions, and the fiber Core, the core consists of germanosilicate doped with a low concentration of ytterbium ions, the concentration of ytterbium ions is 8x10 23 / m 3 , l...

Embodiment 2

[0060] Based on embodiment 1, it also includes FBG5 for enhancing laser feedback, and FBG5 is connected to the pump beam combiner 2 signal end; the structure is as figure 2 shown;

[0061] The concentration of ytterbium ions in double-clad weakly doped ytterbium fiber 3 is 8x10 23 / m 3 The pump laser source 1 is 976nm, the length of FBG5 is 1040nm, and the length of double-clad weakly doped ytterbium fiber 3 is 210m; FBG5 of 1040nm has high reflectivity and low transmittance to 1040nm light; the FBG is set to form a semi-open cavity structure, which enhances The feedback of the laser and the narrow line width of the FBG have a narrowing effect on the laser, thereby achieving a high-power random laser output with a lower threshold and narrower line width. Such as image 3 As shown, as the pump power increases, the laser power also increases continuously, such as Figure 4 The random fiber laser shown is the distribution of laser power along the longitudinal direction of th...

Embodiment 3

[0063] On the basis of Example 2, the pump laser source 1 is selected to be 976nm, the length of the double-clad weakly doped ytterbium fiber 3 is selected to be 170m, and the length of the FBG5 is selected to be 1060nm; the lasing efficiency of random fiber lasers in the 1060nm band can be greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com