Method for recovering a lithium ion battery anode material

A lithium-ion battery and recycling method technology, applied in the field of waste lithium-ion battery treatment, can solve the problems of graphite raw material damage, graphitization difficulty, low reversible capacity, etc., to reduce graphitization temperature and time, and improve cycle stability , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

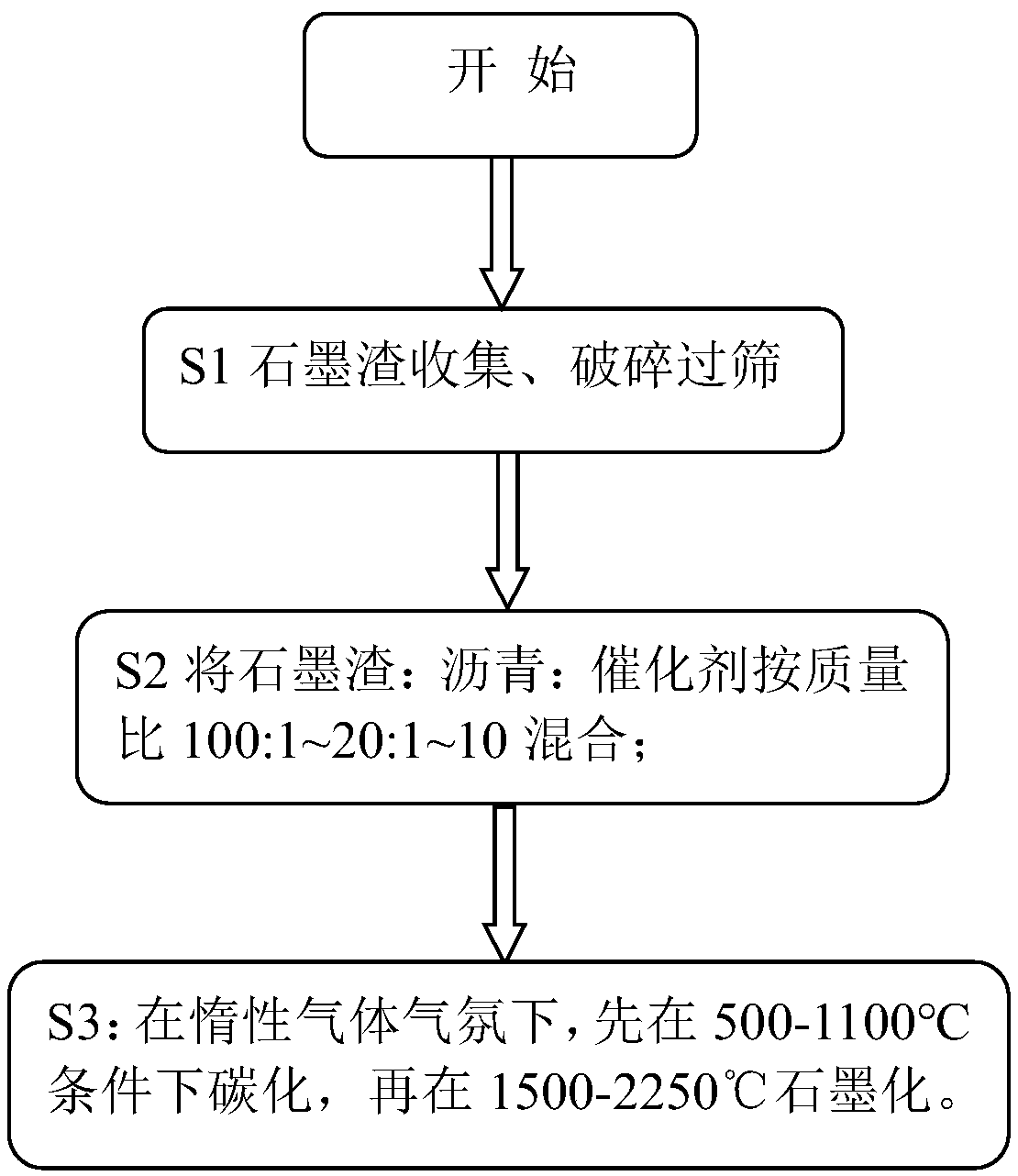

Method used

Image

Examples

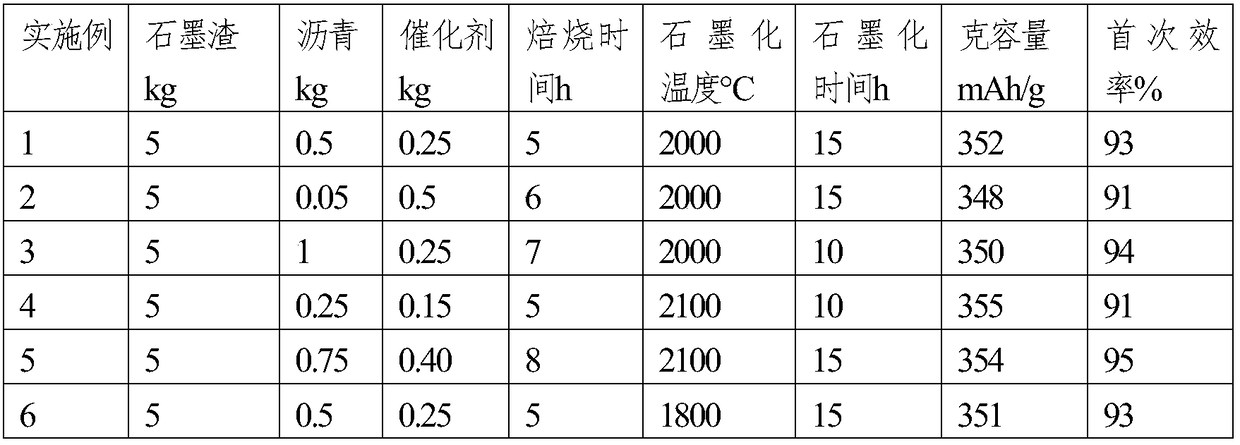

Embodiment 1

[0039] Collect the graphite slag left after the lithium-ion battery recovers metal, crush it and pass it through a 100-mesh sieve to obtain finer and more uniform graphite slag. Take 5kg of graphite slag, 0.5kg of asphalt, and 0.25kg of iron oxide powder, and mix them at a certain temperature. Under inert gas conditions, roast at 900°C for 5h; then transfer to a graphitization furnace, graphitize at 2000°C for 15h, ball mill and sieve, collect sieves with a particle size D50 of 15μm, and obtain a graphite negative electrode material.

Embodiment 2

[0041] Collect the graphite slag left after the lithium-ion battery recovers metal, crush it and pass it through a 100-mesh sieve to obtain finer and more uniform graphite slag. Take 5kg of graphite slag, 0.05kg of asphalt, and 0.5kg of iron oxide powder, and mix them at a certain temperature. Under inert gas conditions, roast at 1000°C for 6h; then transfer to a graphitization furnace, graphitize at 2000°C for 15h, ball mill and sieve, collect sieves with a particle size D50 of 15μm, and obtain graphite negative electrode materials.

Embodiment 3

[0043] Collect the graphite slag left after the lithium-ion battery recovers metal, crush it and pass through a 120-mesh sieve to obtain finer and more uniform graphite slag. Take 5kg of graphite slag with a particle size of less than 100 mesh, 1kg of asphalt, and 0.25kg of boron oxide powder, and mix them at a certain temperature. Under the condition of inert gas, it was roasted at 1100°C for 7h; then transferred to a graphitization furnace, graphitized at 2000°C for 10h, ball milled and sieved, and the sieve with particle size D50 of 15μm was collected to obtain graphite negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com