A method for reducing the surface defect density of silicon carbide epitaxy

A defect density, silicon carbide technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., to achieve the effect of reducing surface defect density, simple and easy epitaxy, and uniform in-situ etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

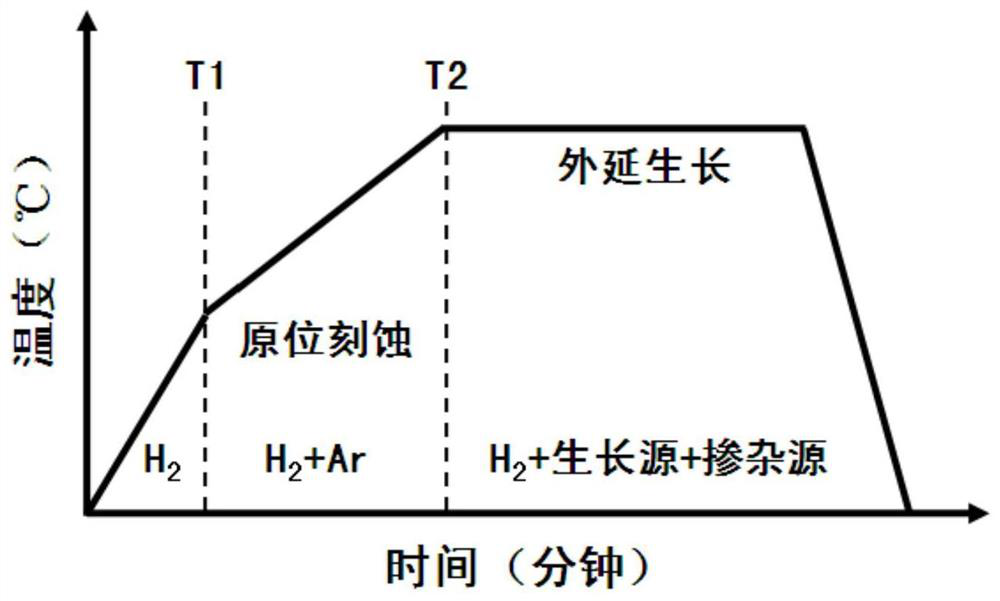

[0024] Such as figure 1 As shown, the method for reducing the surface defect density of silicon carbide epitaxy described in the present invention comprises steps:

[0025] (1) Place the cleaned SiC substrate on the pedestal in the chemical vapor deposition (CVD) equipment. The silicon carbide substrate can be a 3-8 inch silicon carbide substrate that is 4° to the direction;

[0026] (2) set reaction chamber pressure to be 80-150mbar, hydrogen (H 2 ) The flow rate is 80-150L / min, and the system heats up to a temperature of 1400-1500°C;

[0027] (3) Keep the temperature and reaction chamber pressure constant, and perform pure hydrogen etching on the substrate for 1-10 minutes;

[0028] (4) Keep the pressure and H 2 The flow rate is constant, and a small flow rate of argon (Ar) is introduced into the reaction chamber to ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com