Suspended particle type intelligent window preparation method and intelligent window

A suspended particle and intelligent technology, applied in the direction of nonlinear optics, parallel glass structures, instruments, etc., can solve the problems of safety issues that cannot be ignored, SPD driving voltage is large, and achieve high transparency switching rate, strong ability to absorb ultraviolet rays, and easy fill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

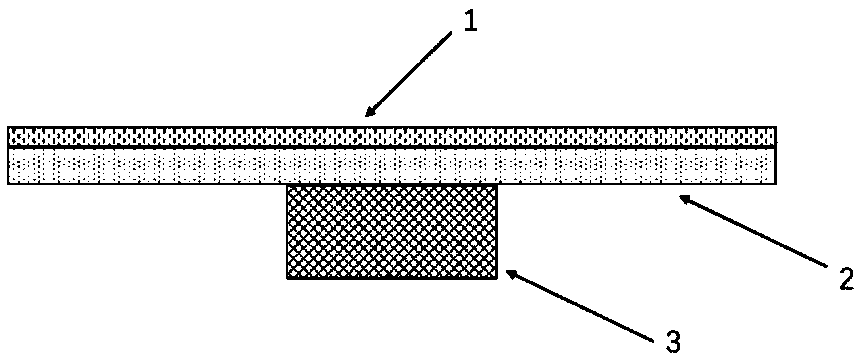

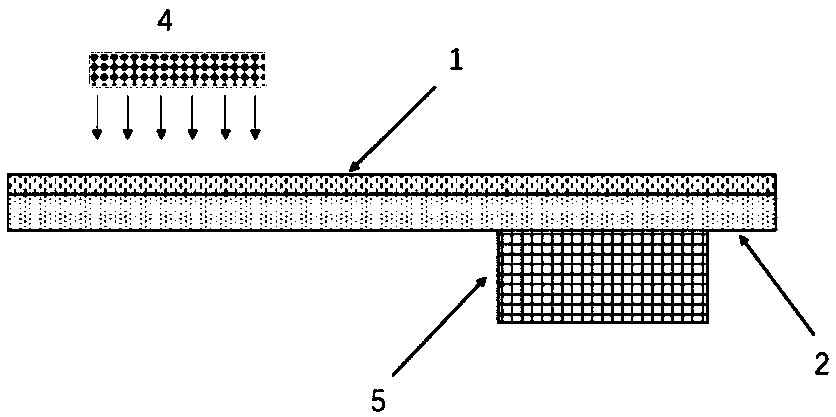

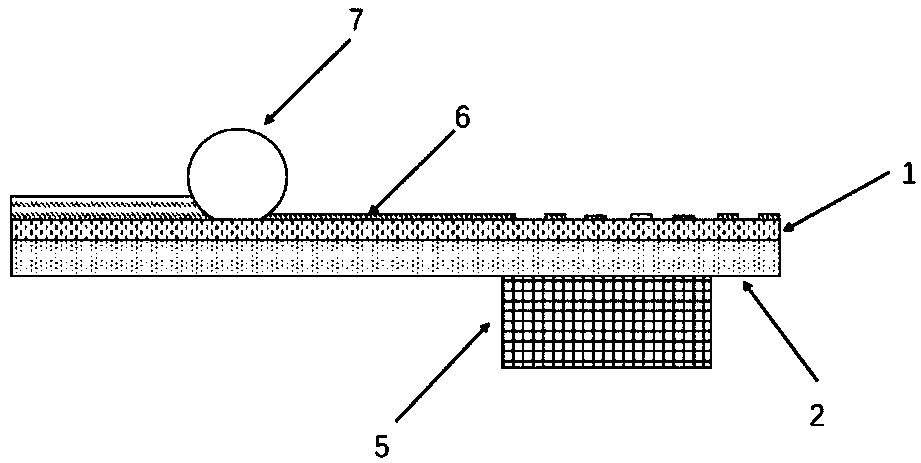

[0056] This embodiment provides a method for preparing a suspended particle-type smart window, which includes the following steps:

[0057] (1) setting a dielectric layer on the transparent substrate;

[0058] (2) curing the dielectric layer and performing a hydrophilic treatment;

[0059] (3) Make a crack template on the dielectric layer:

[0060] (4) Form a crack network transparent conductive electrode on the transparent substrate;

[0061] (5) preparation of modified nano titanium dioxide sol;

[0062] (6) The modified nano-titanium dioxide sol is injected between two cracked network transparent conductive electrodes and encapsulated to obtain a suspended particle smart window.

[0063] It includes four main steps: one is the preparation of dielectric materials and cracking fluid, and the other is the modification of nano-TiO 2 The preparation of the sol changes from water-soluble to oil-soluble. The third is to prepare the dielectric layer and the deposition of the cr...

Embodiment 2

[0086] What this embodiment provides is the intelligent window of suspension particle formula, and what differ from embodiment 1 is that nail polish (model is CA600, commercially available product) is mainly used as cracking liquid and CYTOP as dielectric layer and KH-570 as TiO 2 A modifying agent for nanoparticles, comprising the steps of:

[0087] (1) Preparation of dielectric materials, cracking fluid and

[0088] The method of preparing the cracking fluid is described in detail here.

[0089] Add 10mL of CA600 into the beaker, put it in an ultrasonic cleaner and shake it for 20min, put it in a centrifuge and centrifuge at 5500r / min for 5min, take out the solution and remove the lower sediment, the supernatant is the solution;

[0090] The method for preparing the dielectric layer solution is described in detail here.

[0091] Add 1.0mL of CYTOP diluent to beaker B, then add 1.0mL of 9%wt CYTOP solution, put it into an ultrasonic cleaner and vibrate for 20min, and prepa...

Embodiment 3

[0104] The suspended particle-based intelligent window based on the cracked grid provided in this embodiment is different from Embodiment 1 in that it mainly uses egg white cracking liquid, PAA dielectric layer and DTMS (dodecyltrimethoxy silane) as TiO 2 The modification of nanoparticles comprises the following steps:

[0105] (1) Preparation of dielectric materials, cracking fluid and

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com