Ultraviolet irradiation machine and equipment for making alignment film

A technology of ultraviolet rays and ultraviolet lamps, applied in nonlinear optics, instruments, optics, etc., can solve problems such as EUV process capability decline, reduction of alignment film formation, glass substrate scratches, etc., to reduce the risk of scratches and avoid fragments , to avoid the effect of non-stick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

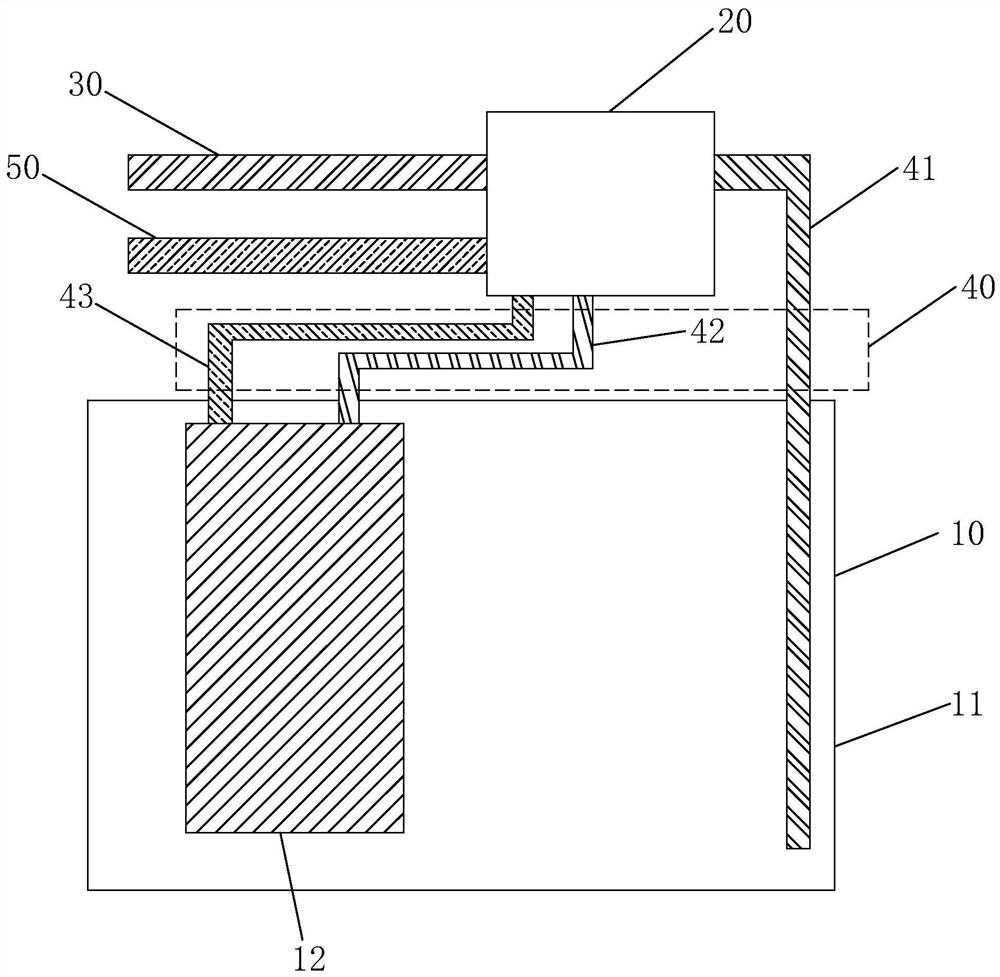

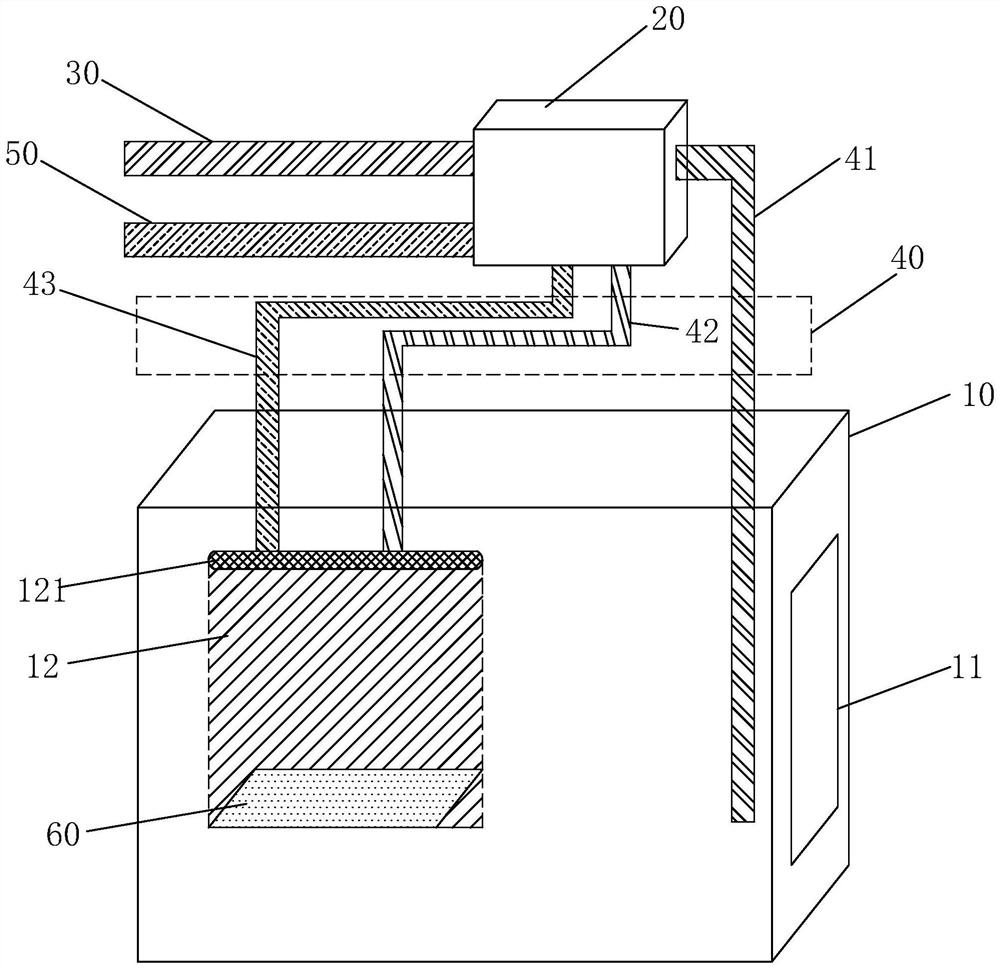

[0029] see figure 1 and figure 2 The present invention provides an ultraviolet irradiation machine comprising: an ultraviolet irradiation machine body 10, a refrigeration device 20 spaced apart from the ultraviolet irradiation machine body 10, a first gas input pipe 30 connected to the refrigeration device 20, and the The gas pipeline 40 that the ultraviolet irradiation machine body 10 and the refrigeration device 20 are all connected;

[0030] The refrigerating device 20 is used to cool the temperature of the first gas input by the first gas input pipe 30 to a range lower than a preset threshold value, and then pass through the gas pipe 40 into the ultraviolet irradiation machine body 10 .

[0031] It should be noted that, the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com