Flexible substrate and preparation method thereof, color film substrate and display panel

A flexible substrate and substrate technology, applied in the direction of nonlinear optics, identification devices, instruments, etc., can solve the problems of high color gamut, low power display panels, etc., to achieve thin design of subsequent devices, simple process, shorten process time and The effect of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

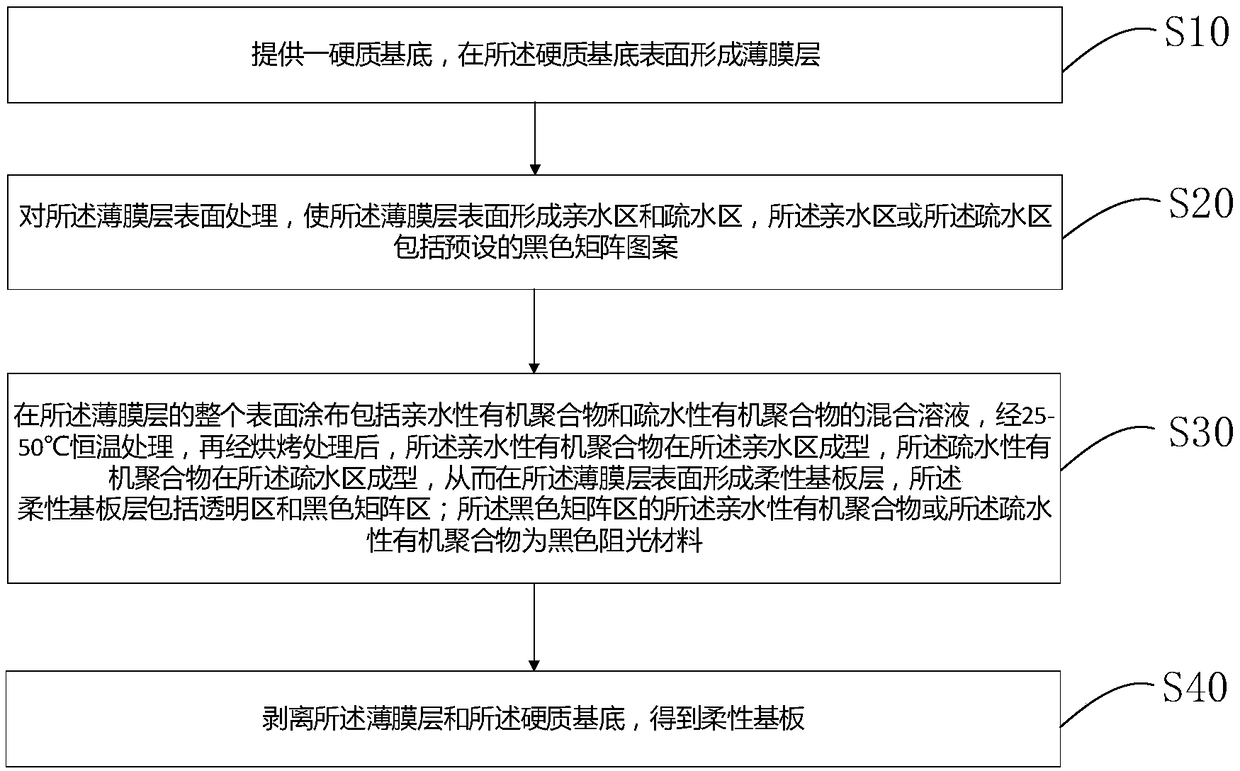

[0036] see figure 1 As shown, the present invention provides a method for preparing a flexible substrate, comprising:

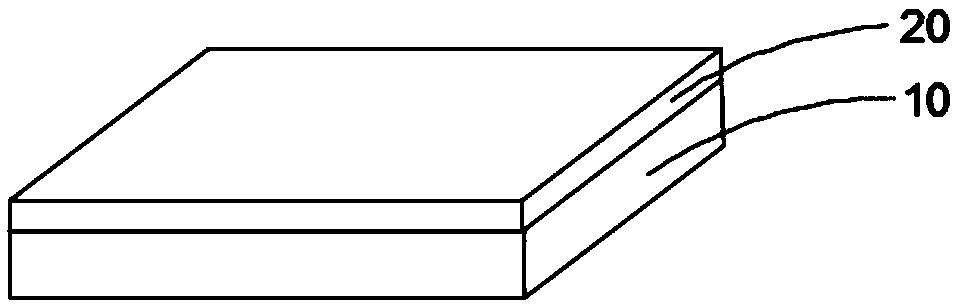

[0037] S10, providing a hard substrate 10, forming a film layer 20 on the surface of the hard substrate 10, see figure 2 ;

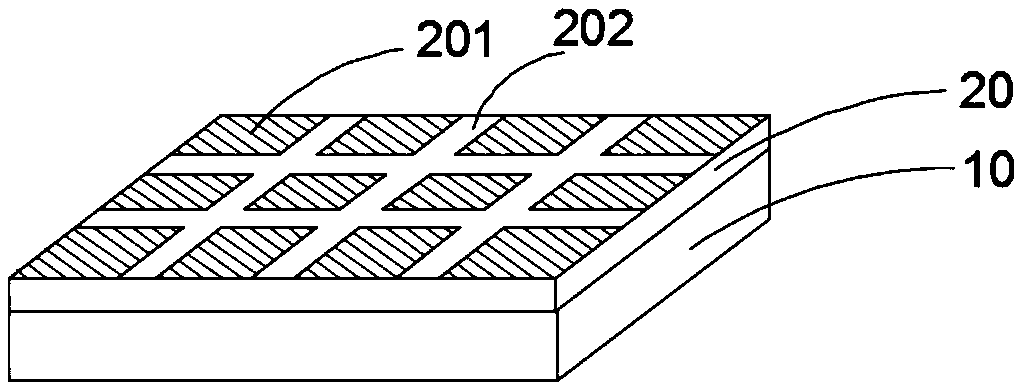

[0038] S20. Treat the surface of the thin film layer 20 to form a hydrophilic region 201 and a hydrophobic region 202 on the surface of the thin film layer 20. The hydrophilic region 201 or the hydrophobic region 202 includes a preset black matrix pattern, see image 3 ;

[0039] S30. Coat the entire surface of the film layer with a mixed solution comprising a hydrophilic organic polymer and a hydrophobic organic polymer, and after a constant temperature treatment at 25-50° C. The polymer is formed in the hydrophilic region, and the hydrophobic organic polymer is formed in the hydrophobic region, thereby forming a flexible substrate layer 40 on the surface of the film layer 20, and the flexible substrate layer 40 includes a transpar...

Embodiment 1

[0067] A method for preparing a flexible substrate, comprising:

[0068] Coating a layer of hydrophobic PET film layer on the surface of a hard substrate; then coating a layer of photoresist material on the PET film, and patterning it on the surface of the PET film layer through exposure, development, etching and other operations Form a photoresist layer, the area not covered with the photoresist layer on the PET film layer is a preset black matrix pattern, and carry out a hydrophilic surface modification treatment on the entire surface of the PET film layer, so that the PET film layer After the film layer has hydrophilicity, the photoresist layer is peeled off; wherein, the surface of the area covered by the original photoresist layer on the surface of the PET film layer is hydrophobic, forming a hydrophobic area; the PET film layer is not covered with The region of the photoresist layer is hydrophilic, forming a hydrophilic region, and obtaining a surface-treated PET film la...

Embodiment 2

[0072] A method for preparing a flexible substrate, comprising:

[0073] Coat a layer of hydrophilic PTFE film layer on the surface of a hard substrate; then coat a layer of photoresist material on the PTFE film, and pattern it on the surface of the PTFE film layer through exposure, development, etching and other operations A photoresist layer is formed on it, and the photoresist layer includes a preset black matrix pattern, and the surface of the entire PTFE film layer is subjected to a hydrophobic surface modification treatment, so that the PTFE film layer is hydrophobic, and the photoresist layer is stripped. Resistance layer; Wherein, the surface of the area covered by the original photoresist layer on the surface of the PTFE film layer is hydrophilic, forming a hydrophilic region; the area not covered with the photoresist layer on the PTFE film layer is hydrophobic , form a hydrophobic region, and obtain a surface-treated PTFE film layer.

[0074] On the surface of the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com