Wire cable conductor DC resistance auxiliary measuring device and measuring method

A DC resistance, wire and cable technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as single-line non-passing current, affecting length measurement accuracy, and limited measurement length, so as to solve the preparatory work Complicated and cumbersome, accurate length measurement results, and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the content of the present invention easier to understand, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

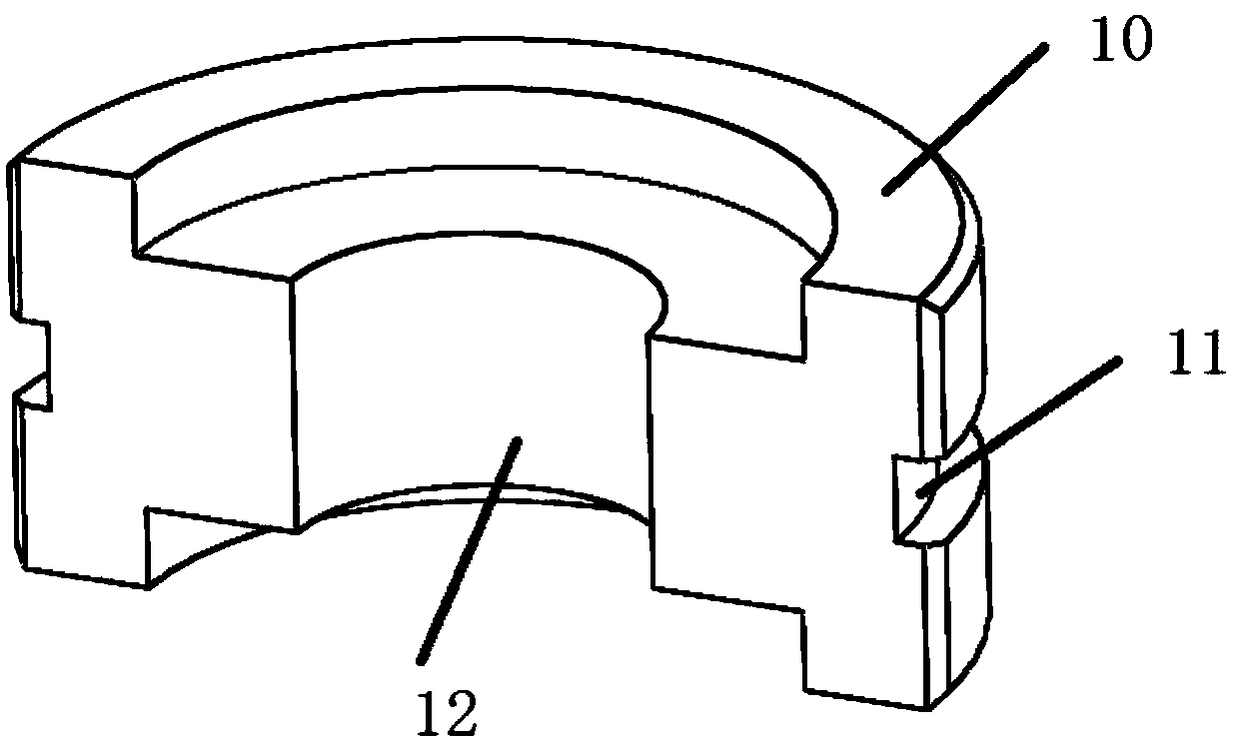

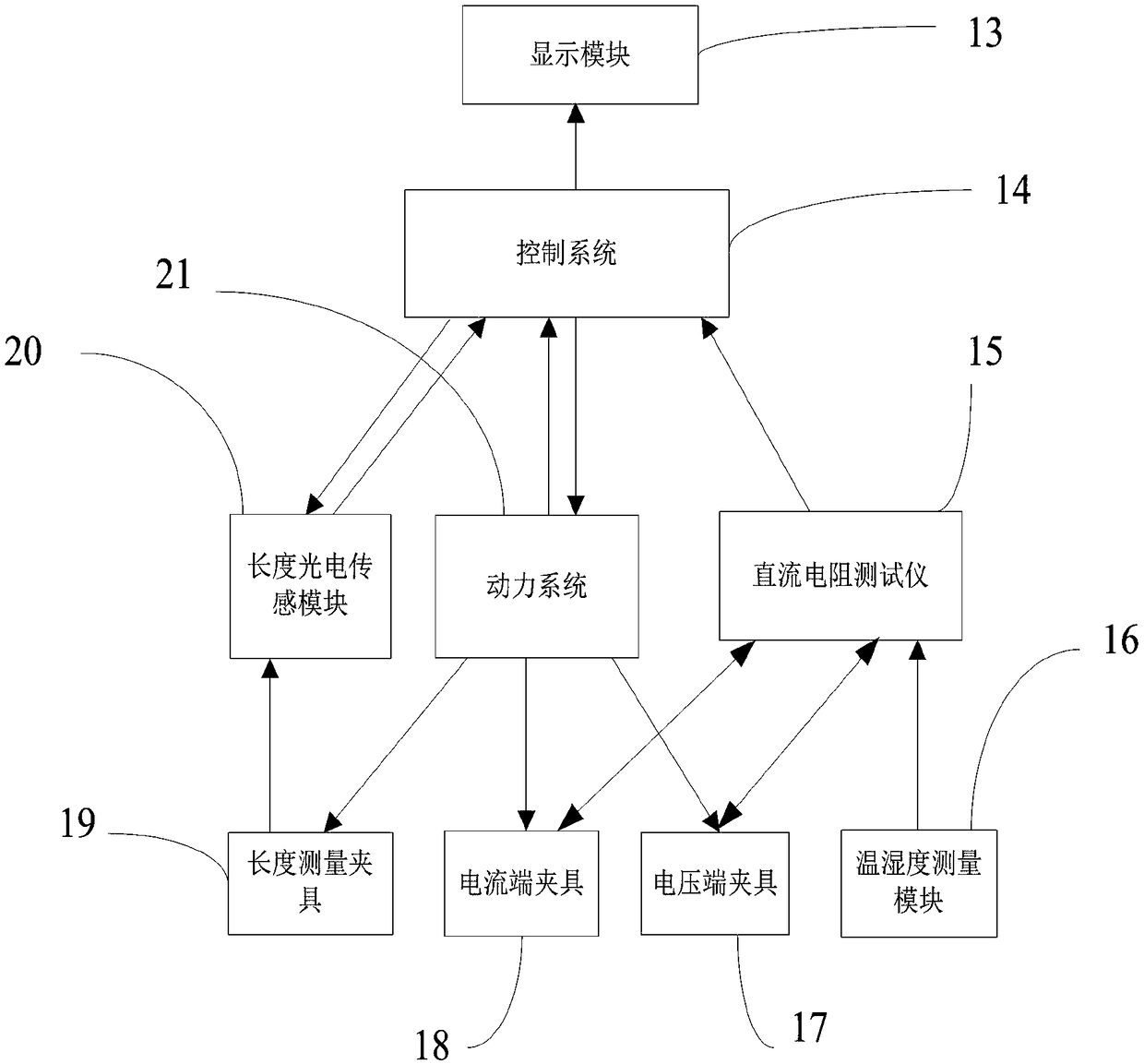

[0032] see Figure 1-Figure 3, an auxiliary measuring device for DC resistance of wire and cable conductors, comprising a current end fixture 18, a potential end fixture 17, a length measurement fixture 19, a length photoelectric sensor module 20, a temperature and humidity measurement module 16, a base 9, a power system 21, and a control system 14 and a display module 13, the current end fixture 18, the potential end fixture 17, the length measurement fixture 19, and the length photoelectric sensor module 20 are respectively connected to the base, and the control system-14 is connected with the power system-21, the length photoelectric sensor Module-20, DC resistance tester-15, and display module-13 are connected, the temperature and humidity measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com