Method for measuring dynamic full-surface local strain and uniformity of sand tri-axial test sample by utilizing digital image processing technology

A triaxial sample and technical measurement technology, applied in image data processing, applying stable tension/pressure to test material strength, image enhancement, etc., to achieve the effect of simple operation steps, avoiding interference, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with example, the present invention is described in detail:

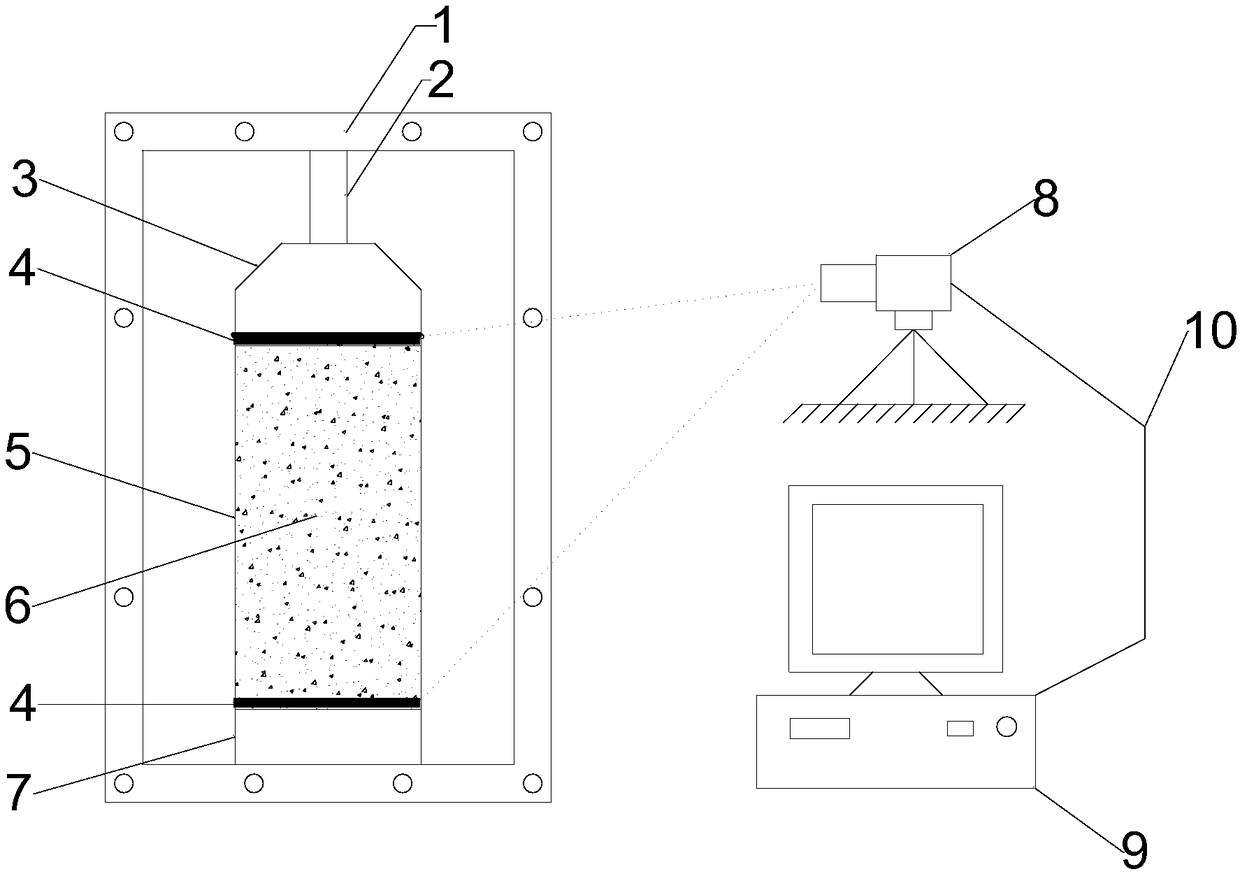

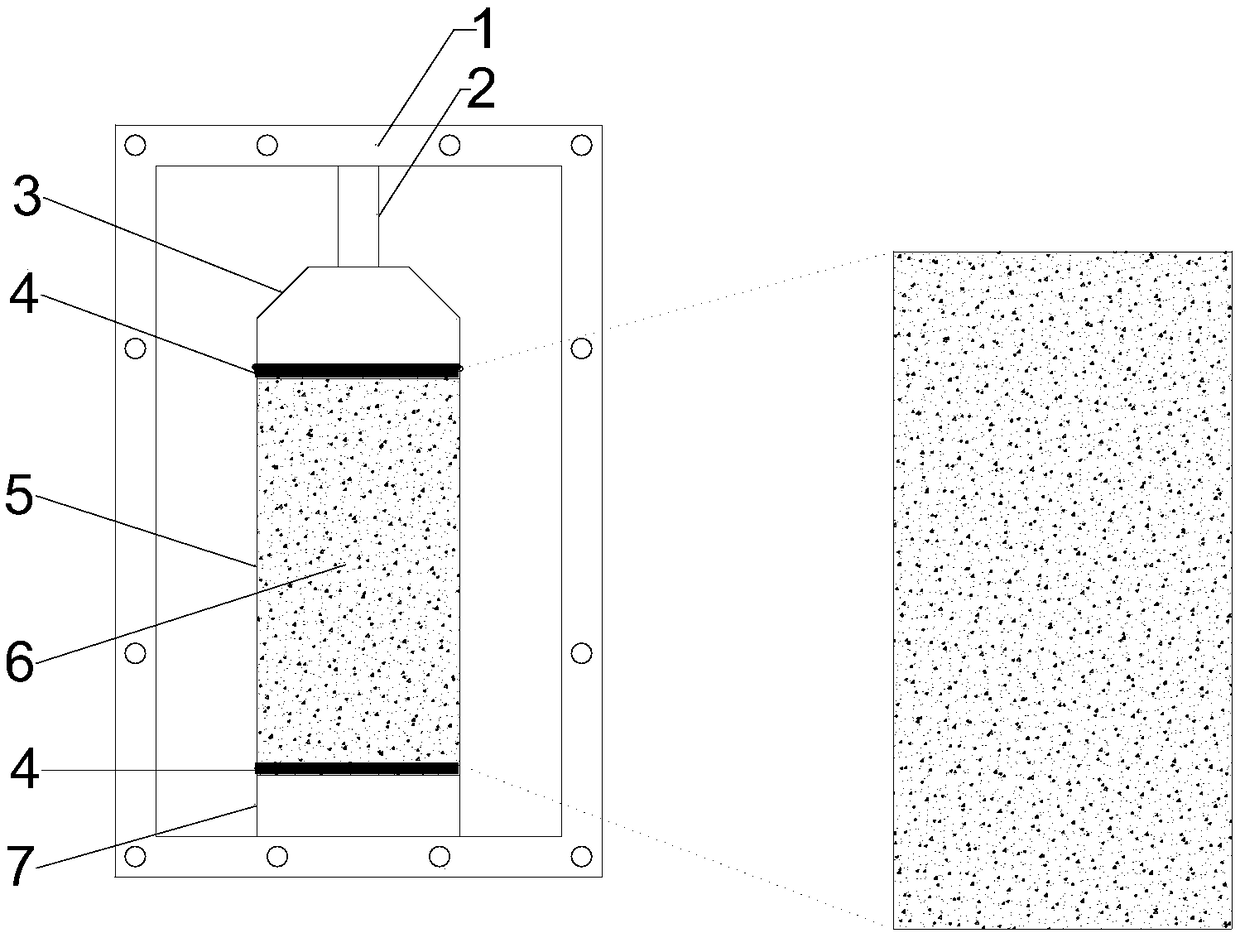

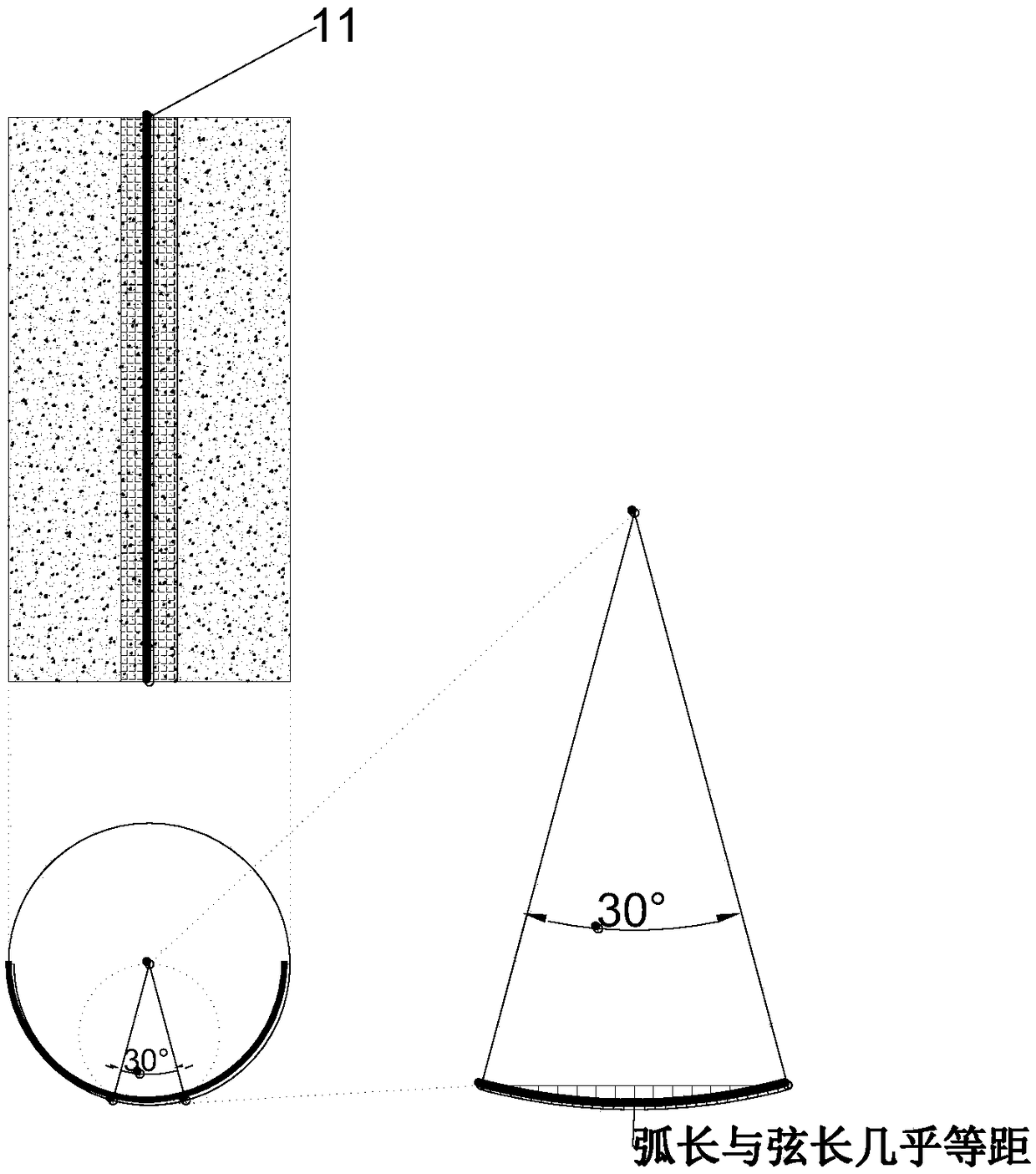

[0027] A method for measuring the dynamic full-surface variable strain and its uniformity of a triaxial sample using digital image processing technology is realized based on a small triaxial tester 1, and the test device includes a high-speed industrial camera 8, a computer 9 and a high-speed data acquisition line 10. Specifically include the following steps:

[0028] (1) Adopt small-scale triaxial instrument 1 test equipment, prepare triaxial sample 6 by routine test method in " soil engineering test regulation " (SL237-1999), utilize sandy soil to finish present embodiment test, sandy soil gradation is as follows Figure 5 shown.

[0029] (2) Using spray paint (black and white) to perform full-field speckle treatment on the surface of the latex film 5 . Spray a uniform black base first, and then spray white speckles randomly after drying. The black bottom layer makes the image clear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com