Early strength type polycarboxylic acid water reducer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixture, can solve the problems of concrete centrifugal dehydration difficulty, long static stop time of pipe piles, and rough inner wall, etc., and achieves easy operation, obvious early strength effect, and high production capacity The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

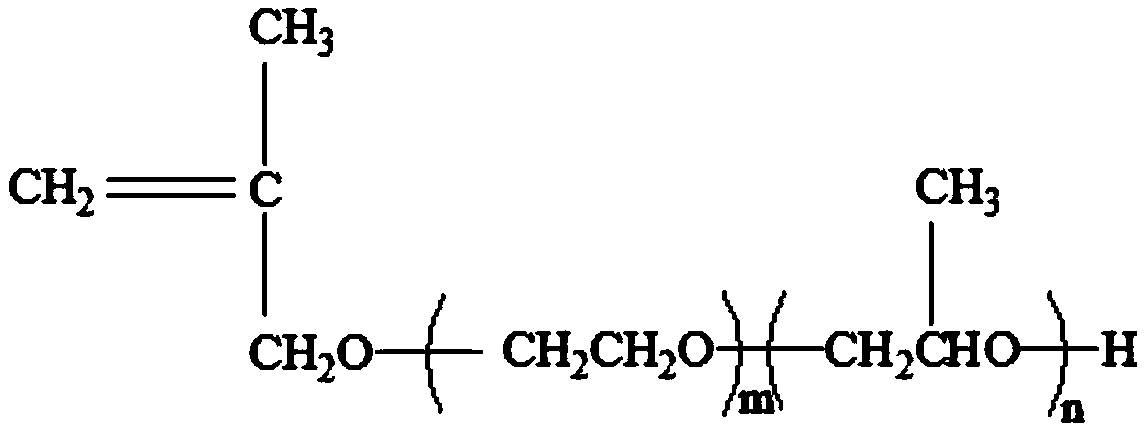

[0018] The invention provides an early-strength polycarboxylate water-reducer and a preparation method thereof. Polyether with an early-strength function is used as a synthetic macromonomer, and a polymeric small monomer with an early-strength function is introduced during the synthesis process. According to Based on the principle of free radical polymerization, under the action of oxidation-reduction initiation system, an early-strength polycarboxylate water-reducer is prepared by double-dropping method, which has the performance of significantly improving the early strength of concrete.

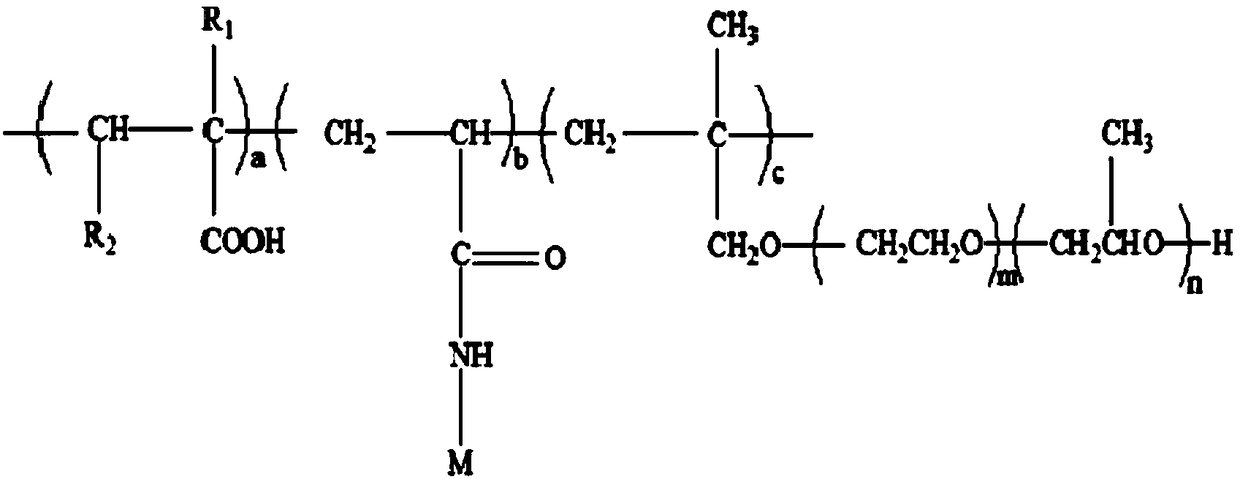

[0019] The present invention provides an early-strength polycarboxylate water-reducer, the early-strength polycarboxylate water-reducer has a molecular weight of 40,000-60,000, and its molecular formula is as follows:

[0020]

[0021] In the formula, R 1 = H or CH 2 COOH or CH 3 ;

[0022] R 2 = H or COOH;

[0023] M=H or CH 2 OH or C(CH 3 ) 2 CH 2 SO 3 Na,

[0024] m=0-120, ...

Embodiment 1

[0049] First, 100 parts of polyether macromonomers with a weight average molecular weight of 3800-6000 were weighed and dissolved in water, with a mass concentration of 63.3%. Make it dissolve at 40°C to obtain the first mixed solution,

[0050] Next, 11.75 parts of acrylic acid were mixed to form an aqueous solution to obtain a second mixed solution with a concentration of 67.7%, and 0.12 parts of ascorbic acid and 0.33 parts of thioglycolic acid were mixed to form an aqueous solution to obtain a third mixed solution with a concentration of 1.7%.

[0051] Again, when the temperature is 40°C, add all 0.37 parts of hydrogen peroxide. After 5-10 minutes, start to add the second mixed solution and the third mixed solution dropwise. The second mixed solution is added dropwise for 3 hours, and the third mixed solution is added dropwise for 3 hours. After the mixed solution is dripped, react for 1 hour while keeping the temperature constant, adjust the pH value to 6-7 with lye, and ...

Embodiment 2

[0053] First, 100 parts of polyether macromonomer with a weight average molecular weight of 3800-6000 and 3 parts of acrylic acid were dissolved in water, and dissolved at 25°C to obtain the first mixed solution with a mass concentration of 58%.

[0054] Next, mix 9 parts of acrylic acid to form an aqueous solution to obtain a second mixed solution with a mass concentration of 65%, and mix 0.1 part of ascorbic acid and 0.2 part of mercaptopropionic acid to form an aqueous solution to obtain a third mixed solution with a mass concentration of 1.5%.

[0055] Again, when the temperature is 25°C, add all 0.25 parts of ammonium persulfate. After 5-10 minutes, start to add the second mixed solution and the third mixed solution dropwise. The second mixed solution is added dropwise for 2 hours, and the third mixed solution is added dropwise for 2.5 minutes. hour, after the third mixed solution is dripped, the temperature is kept constant for 1 hour, the pH value is adjusted to 6-7 with l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com