Novel early-strength polycarboxylate superplasticizer

A water-reducing agent and early-strength type technology, which is applied in the field of new-type early-strength polycarboxylate water-reducing agent, can solve problems such as prolonging the setting time of concrete, darkening the appearance of concrete components, and lacking a sense of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

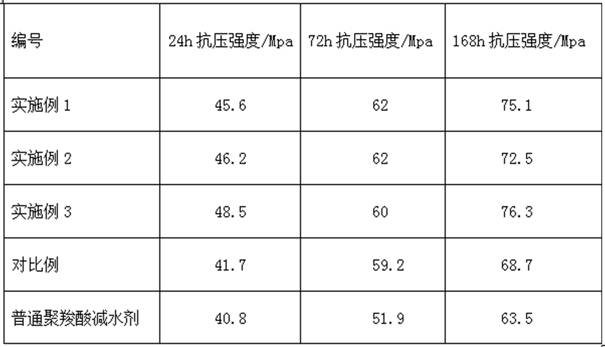

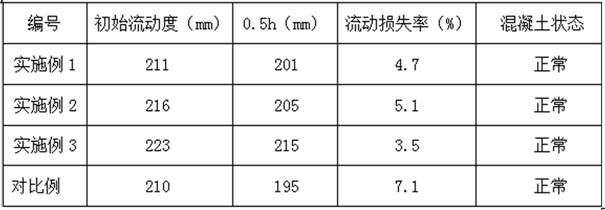

Examples

Embodiment 1

[0015] The preparation method of early-strength polycarboxylate water reducer comprises the following steps:

[0016] 1) First put 50 parts of water and 50 parts of polycarboxylate water reducer into the reaction kettle, stir until dissolved, and heat to 65°C;

[0017] 2) Add 3 parts of glucose, 5 parts of methacrylic acid, and 1 part of mercaptopropionic acid to it at the same time. After 1.8 hours of heat preservation, add alkali to neutralize to pH 6-7, and replenish water until the solid content is 45%. Strong polycarboxylate superplasticizer.

Embodiment 2

[0019] The preparation method of early-strength polycarboxylate water reducer comprises the following steps:

[0020] 1) First, put 70 parts of water and 30 parts of polycarboxylate water reducer into the reaction kettle, stir until dissolved, and heat to 70°C;

[0021] 2) Add 5 parts of glucose, 10 parts of methacrylic acid, and 2 parts of thioglycolic acid to it at the same time. After 1.5 hours of heat preservation, add alkali to neutralize to pH 6-7, and replenish water until the solid content is 46%, and the early-strength type is obtained. Polycarboxylate superplasticizer.

Embodiment 3

[0023] The preparation method of early-strength polycarboxylate water reducer comprises the following steps:

[0024] 1) First put 40 parts of water and 60 parts of polycarboxylate water reducer into the reaction kettle, stir until dissolved, and heat to 85°C;

[0025] 2) Add 2 parts of sodium citrate, 3 parts of methacrylic acid, and 2 parts of mercaptopropionic acid to it at the same time. After keeping warm for 2 hours, add alkali to neutralize the pH to 6-7, and replenish water until the solid content is 42%. Early strength polycarboxylate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com