Continuous dilution device and continuous dilution method for cooling devitrification of 4-acetamidobenzenesulfonyl chloride

A technology of acetaminobenzenesulfonyl chloride and dilution device, which is applied in the direction of mixing methods, chemical instruments and methods, crystallization separation, etc., can solve the problems of high equipment cost, large floor area, and high labor intensity, and achieve uniform crystal particle size , less cooling water consumption and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

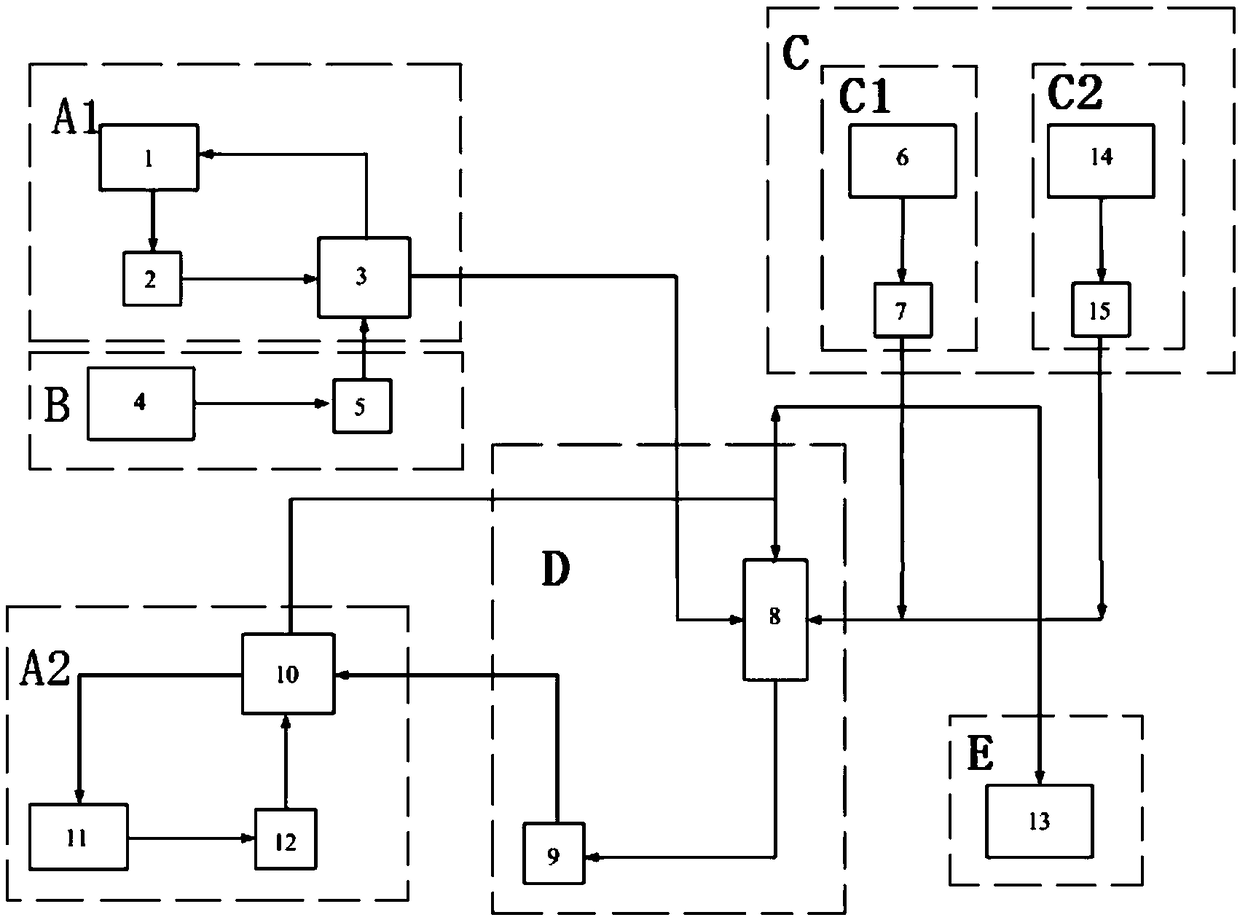

[0037] Embodiment 1 The continuous dilution device used for the cooling and crystallization process of acetaminobenzenesulfonyl chloride according to the present invention comprises:

[0038] Two sets of heat exchange units (A1, A2), wherein the tube side inlet of the first heat exchange unit A1 is connected with the outlet pipeline of the dilution unit, and the tube side outlet is connected with the feed port pipeline of the mixed circulation unit, for Heat exchange for dilution water; while the tube side inlet of the second set of heat exchange unit A2 is connected with one of the feed inlet pipelines of the mixed circulation unit, and the tube side outlet is connected with the corresponding feed inlet pipeline of the continuous dilution mixed circulation unit Connected, used to cool down the diluted material to crystallize the paracetamol sulfonyl chloride;

[0039]The dilution water unit B includes a dilution water tank 4 and a dilution water discharge pump 5. The outlet o...

Embodiment 2

[0052] Example 2 The serial dilution device used in the cooling and crystallization process of acetaminobenzenesulfonyl chloride described in this example, specifically, the outlet of the No. 1 cooling water tank 1 is connected to the inlet of the No. 1 cooling water circulating pump 2, The outlet of the No. 1 cooling water circulation pump 2 is connected to the shell-side inlet of the No. 1 cooling water heat exchanger 3, and the shell-side outlet of the No. 1 cooling water heat exchanger 3 is connected to the feed inlet of the No. 1 cooling water tank 1. , the outlet of the dilution water tank 13 is connected to the inlet of the dilution water discharge pump, the outlet of the dilution water discharge pump 5 is connected to the inlet of the No. 1 cooling water heat exchanger 3 tubes, and the No. 1 cooling water The outlet of the tube side of the water heat exchanger 3 is connected with the feed port of the pipeline mixer 8, the discharge port of the acetaminobenzenesulfonyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com