Fluorgypsum-based self-leveling floor material and preparation method thereof

A gypsum-based, fluorogypsum technology, applied in the field of new building materials, can solve the problems of polluted soil and groundwater environment, poor water resistance and wear resistance, drying shrinkage, hardening shrinkage, etc., and achieve high volume energy storage density, good fluidity, The effect of small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Fluorogypsum-based self-leveling floor materials are prepared as follows:

[0078] Step 1: Preparation of inorganic low-temperature phase-change energy storage and heat storage materials: pre-treat the packaging material (expanded perlite, 24 parts by weight) (after screening, place it in an oven for drying), put it into a 55°C water bath and continuously Stir (rotating speed is 6000rpm), utilize the capillary adsorption force of expanded perlite to mix the inorganic low-temperature phase change material (KAl(SO 4 ) 2 12H 2 O, 18 parts by weight) is adsorbed in its pore structure to make an inorganic low-temperature phase change energy storage heat storage material. Weigh 10 parts by weight of the inorganic low-temperature phase-change energy storage and heat storage material for use.

[0079] Step 2: The activator KAl(SO 4 ) 2 12H 2 0 is pulverized and ground to about 200 orders, and takes 2.78 parts by weight;

[0080] Step 3: Take 100 parts by weight of fluoro...

Embodiment 2

[0098] The method for preparing the fluorogypsum-based self-leveling floor material is the same as in Example 1, except that:

[0099] Fluorogypsum (74um) is 100 parts by weight, sulfoaluminate cement is 15 parts by weight, K 2 SO 4 2.78 parts by weight, 25 parts by weight of inorganic low-temperature phase change energy storage material, 0.8 parts by weight of polycarboxylate water reducer as water reducing agent, 3 parts by weight of redispersible latex powder, and 0.1 parts by weight of stabilizer Starvis 3003F , The filler is 60 parts by weight (70-90 mesh), and the water is 30 parts by weight.

[0100] The preparation of the fluorogypsum-based self-leveling floor mortar was the same as in Example 1.

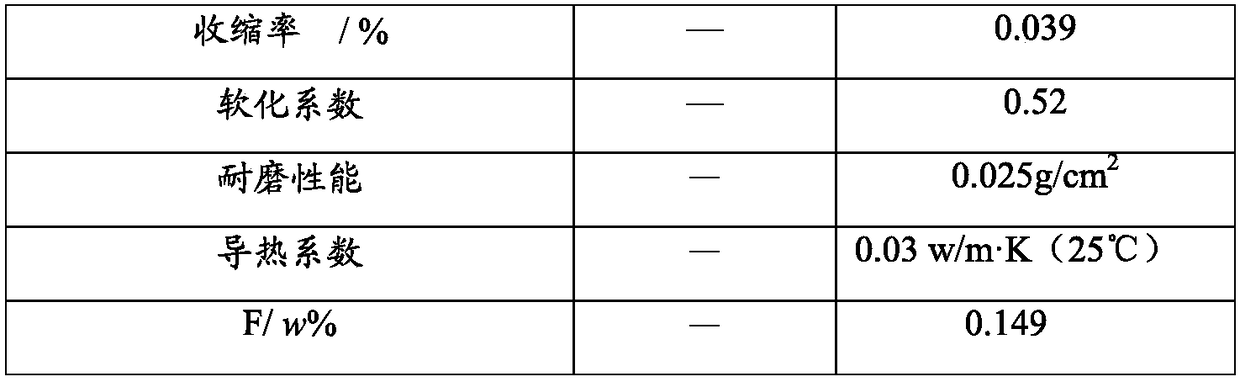

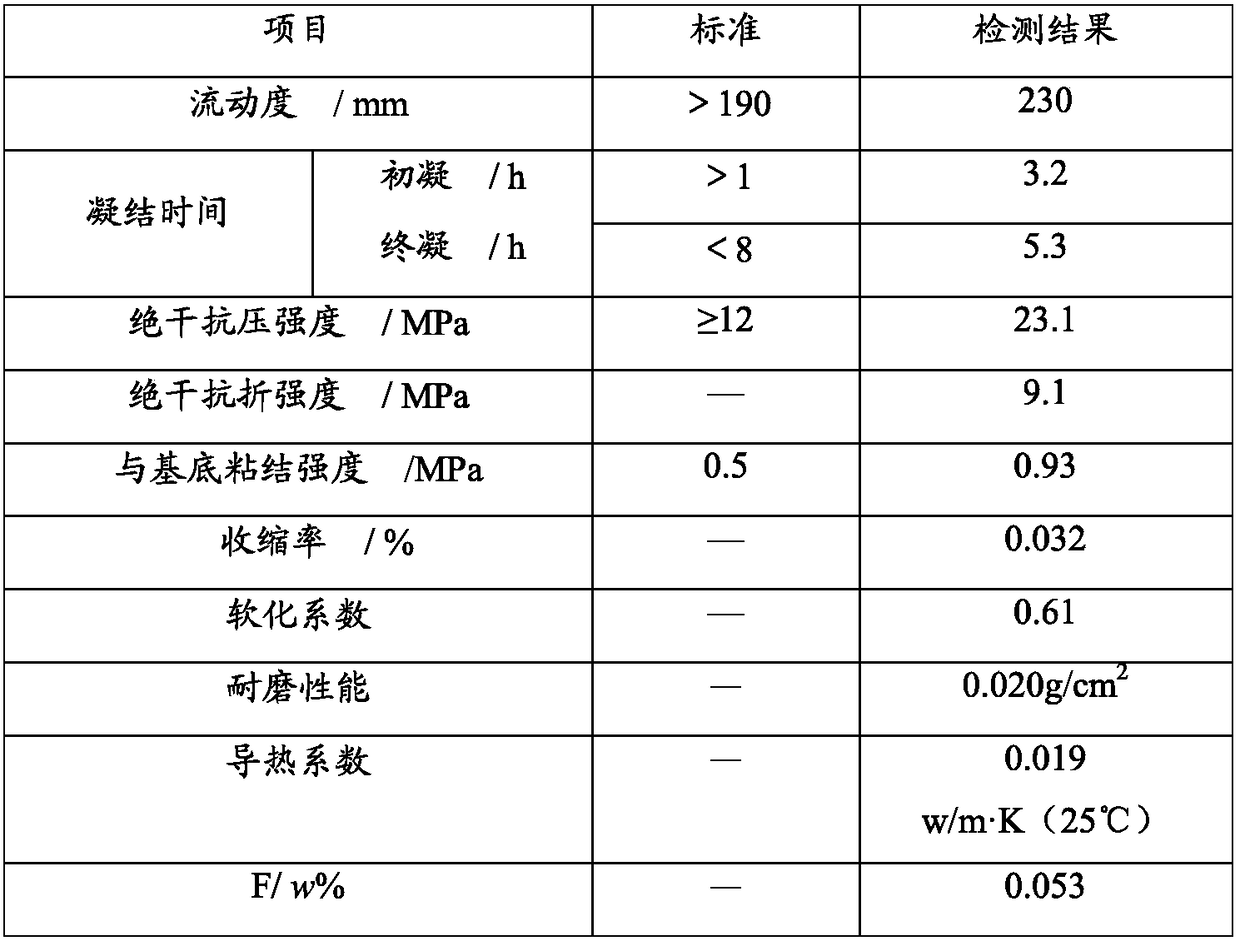

[0101] The performance test of the fluorogypsum-based self-leveling mortar produced in Example 2 was carried out according to the test method described in Example 1, and the results are shown in Table 2 below:

[0102] Table 2

[0103]

Embodiment 3

[0105] The method for preparing the fluorogypsum-based self-leveling floor material is the same as in Example 1, except that:

[0106] Fluorogypsum (149um) is 100 parts by weight, sulfoaluminate cement is 24 parts by weight, acid activator is 12 parts by weight of potassium alunite mineral, inorganic low temperature phase change energy storage material is 15 parts by weight, pyrimidine resin water reducing The agent is 0.7 parts by weight, the redispersible latex powder is 2 parts by weight, the stabilizer Starvis 3003F is 0.07 parts by weight, the filler (70-90 mesh) is 50 parts by weight, and the water is 25 parts by weight. Among them, the acid activator potassium alunite mineral is calcined at 550°C for 2 hours after pretreatment, cooled at room temperature and then ground to about 200 mesh.

[0107] The preparation of the fluorogypsum-based self-leveling floor mortar is basically the same as in Example 1.

[0108] The performance test of the fluorogypsum-based self-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com