Efficient special fiber anti-cracking agent and preparation method thereof

A special fiber and anti-cracking agent technology, applied in the field of high-efficiency special fiber anti-cracking agent and its preparation, can solve the problems of increased slump loss of fluidized concrete, large reduction of water absorption ratio, slow water absorption speed, etc. The effect of increasing temperature shrinkage stress, reducing temperature shrinkage cracks, and reducing the temperature rise of heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

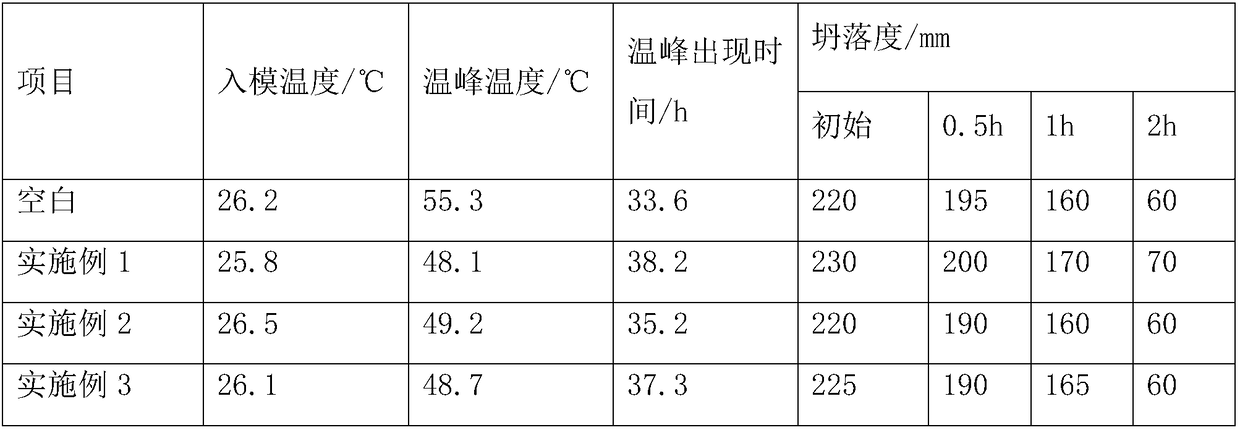

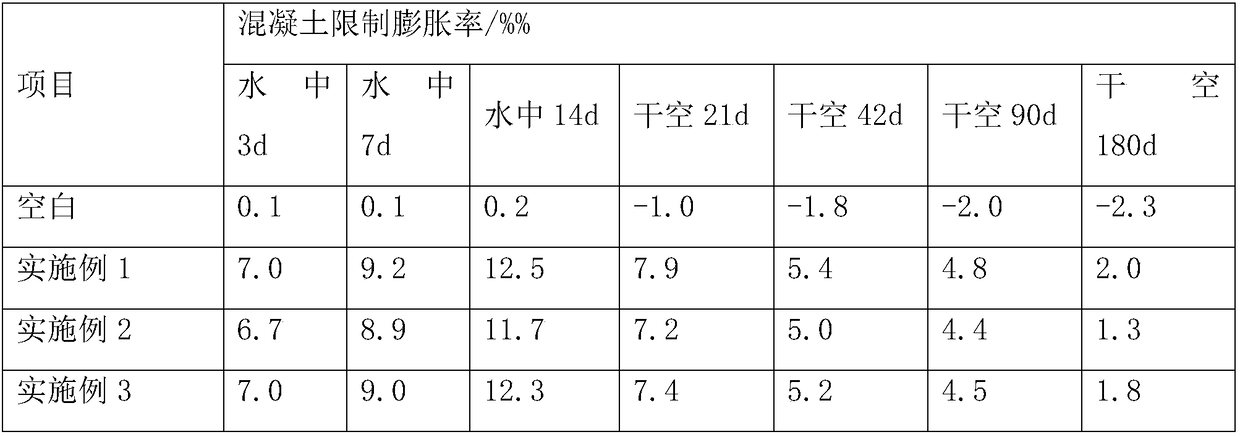

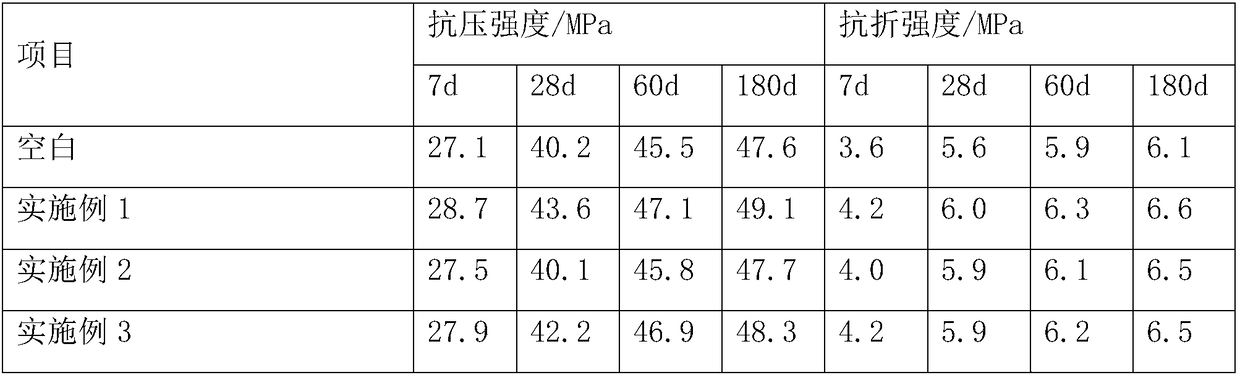

Examples

Embodiment 1

[0058] In this embodiment, the high-efficiency special fiber anti-cracking agent components (by mass) include: hydration heat inhibiting expansion agent 55wt%, basalt fiber 22.5wt%, corn starch 22.5wt%.

[0059] Wherein, the heat of hydration inhibiting expansion clinker is 85wt% and the gypsum is 15wt% in the heat of hydration inhibiting expansion agent.

[0060] The preparation process is as follows: (1) 78% limestone, 7% gypsum, 5% iron slag, 5% bauxite and 5% zinc oxide are ground together, and calcined in a rotary kiln at 1300 ° C, and its composition is SiO 2 3.52%, Fe 2 o 3 1.39%, Al 2 o 3 5.11%, CaO76.3%, SO 3 8.03%, MgO 2.38%.

[0061] The basalt fiber has a nominal diameter of 10μm, a nominal length of 15mm, and a density of 2.6g / cm 3 , tensile strength 4000MPa, modulus of elasticity 94GPa, elongation at break 2.8%, moisture content 0.06%.

[0062] (2) Mix heat of hydration inhibited expansion clinker with gypsum and grind together until the specific surfa...

Embodiment 2

[0066] In this embodiment, the high-efficiency special fiber anti-cracking agent components (by mass) include: hydration heat inhibiting expansion agent 55wt%, basalt fiber 15wt%, steel fiber 7.5wt%, corn starch 22.5wt%.

[0067] Wherein, the heat of hydration inhibiting expansion clinker is 85wt% and the gypsum is 15wt% in the heat of hydration inhibiting expansion agent.

[0068] The preparation process is as follows: (1) 78% limestone, 7% gypsum, 5% iron slag, 5% bauxite and 5% zinc oxide are ground together, and calcined in a rotary kiln at 1300 ° C, and its composition is SiO 2 3.52%, Fe 2 o 3 1.39%, Al 2 o 3 5.11%, CaO76.3%, SO 3 8.03%, MgO 2.38%.

[0069] The basalt fiber has a nominal diameter of 10μm, a nominal length of 15mm, and a density of 2.6g / cm 3 , tensile strength 4000MPa, modulus of elasticity 94GPa, elongation at break 2.8%, moisture content 0.06%.

[0070] Steel fiber length 20mm, diameter 0.5mm, density 7.8g / cm3, tensile strength ≥ 600MPa, elast...

Embodiment 3

[0075]The high-efficiency special fiber anti-cracking agent components in this embodiment (by mass) include: hydration heat inhibiting expansion agent 55wt%, basalt fiber 15wt%, polypropylene fiber 7.5wt%, cornstarch 22.5wt%.

[0076] Wherein, the heat of hydration inhibiting expansion clinker is 85wt% and the gypsum is 15wt% in the heat of hydration inhibiting expansion agent.

[0077] (1) Heat of hydration inhibited expansion clinker is calcined at 1300°C in a rotary kiln with 78% limestone, 5% bauxite, 5% iron slag, 7% gypsum and 5% zinc oxide, and its composition is SiO 2 3.52%, Fe 2 o 3 1.39%, Al 2 o 3 5.11%, CaO 76.3%, SO 3 8.03%, MgO 2.38%.

[0078] The basalt fiber has a nominal diameter of 10μm, a nominal length of 15mm, and a density of 2.6g / cm 3 , tensile strength 4000MPa, modulus of elasticity 94GPa, elongation at break 2.8%, moisture content 0.06%.

[0079] Polypropylene fiber length 19mm, diameter 4.8μm, density 0.91g / cm3, tensile strength ≥ 400MPa.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com