Preparation method of element-doped porous g-C3N4 nano-sheets

An element doping, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of high exciton binding energy, easy recombination, low specific surface area, etc., to achieve strong light absorption ability, low preparation cost, high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

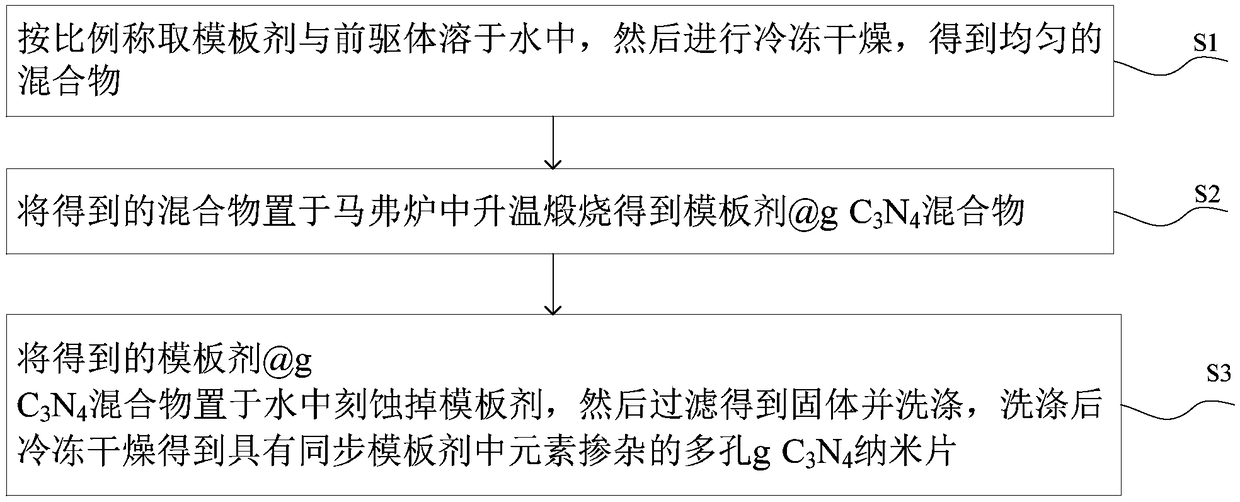

[0024] Please refer to figure 1 , an embodiment of the present invention provides an element-doped porous g-C 3 N 4 The preparation method of nano sheet, comprises the following steps:

[0025] (1) Take the template agent and the precursor in proportion and dissolve them in water, then freeze-dry to obtain a uniform mixture; the mass ratio of the template agent to the precursor is 2 to 40:1, the template agent uses sodium chloride, and the precursor It is dicyandiamide; the freeze-drying temperature is -15~-30°C; during the freezing process, sodium chloride and dicyandiamide are precipitated in the form of crystals, and the two can be mixed evenly. The template agent sodium chloride is a mineral rock salt. The main component is rich in reserves, easy to obtain, and low in cost, which is conducive to industrial production;

[0026] (2) Place the obtained mixture in a muffle furnace to heat up and calcinate to obtain the template @g-C 3 N 4 Mixture; the heating rate is 5-15...

Embodiment 2

[0035] Preparation of sodium-doped porous g-C according to the method of Example 1 of the present invention 3 N 4 Nanosheets, comprising the steps of:

[0036] (1) 2g of sodium chloride and 1g of dicyandiamide were co-dissolved in 150mL of deionized water, and then the solution was freeze-dried to obtain a homogeneous mixture of sodium chloride and dicyandiamide;

[0037] (2) Put the homogeneous mixture of sodium chloride and dicyandiamide in a muffle furnace for calcination at 550°C for 4 hours, the heating rate is 2.3°C / min, take it out after natural cooling, and obtain sodium chloride@g-C 3 N 4 mixture;

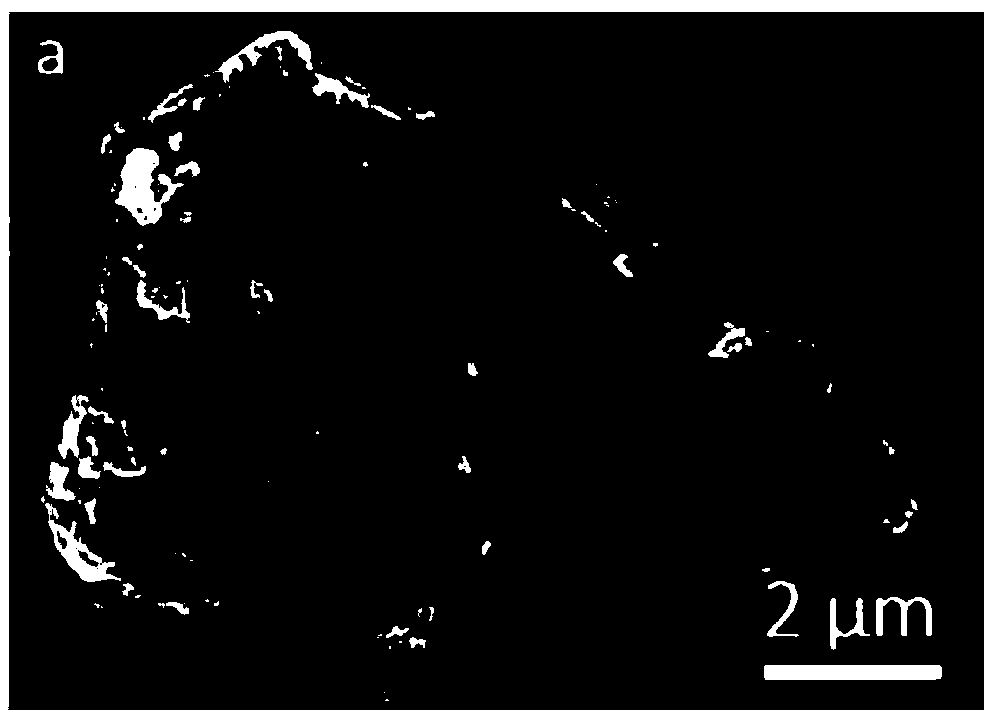

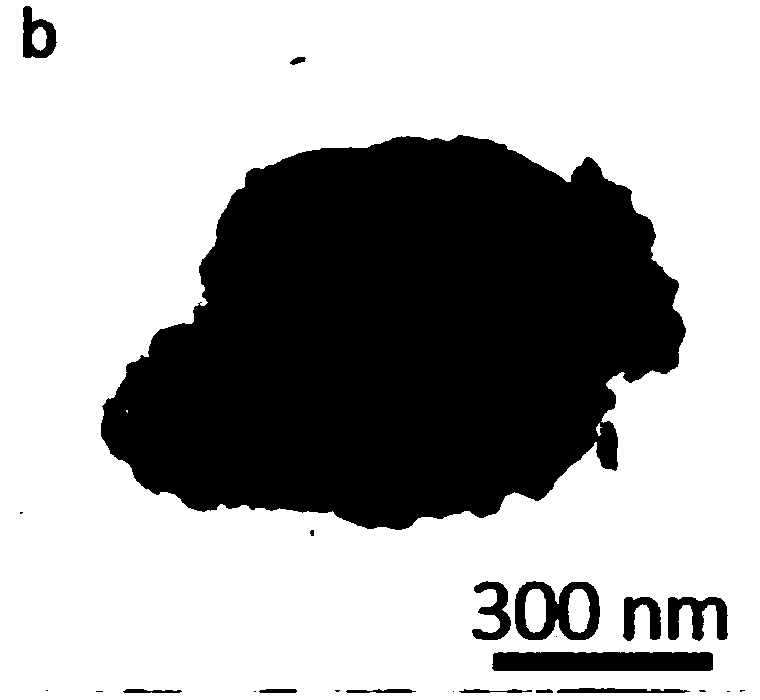

[0038] (3) The obtained sodium chloride@g-C 3 N 4 The mixture was placed in 150 mL of deionized water and stirred at room temperature for 10 h, then suction filtered until the conductivity of the filtrate dropped below 10, and the obtained pale yellow solid was freeze-dried to obtain porous g-C with sodium doping. 3 N 4 Nanosheet; its visible light catalytic water s...

Embodiment 3

[0041] Preparation of sodium-doped porous g-C according to the method of Example 1 of the present invention 3 N 4 Nanosheets, comprising the steps of:

[0042] (1) 10g of sodium chloride and 1g of dicyandiamide were co-dissolved in 150mL of deionized water, and then the solution was freeze-dried to obtain a homogeneous mixture of sodium chloride and dicyandiamide;

[0043] (2) High-temperature calcination: put the uniform mixture of sodium chloride and dicyandiamide in a muffle furnace for calcination at 550°C for 4 hours, the heating rate is 2.3°C / min, take it out after natural cooling, and obtain sodium chloride@g-C 3 N 4 mixture;

[0044] (3) The obtained sodium chloride@g-C 3 N 4 The mixture was placed in 150 mL of deionized water and stirred at room temperature for 10 h, then suction filtered until the conductivity of the filtrate dropped below 10, and the obtained pale yellow solid was freeze-dried to obtain porous g-C with sodium doping. 3 N 4 Nanosheets; its vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com